Method for manufacturing high chromium white wear-resistant cast iron

A wear-resistant cast iron, manufacturing method technology, applied in the direction of manufacturing tools, heat treatment baths, heat treatment equipment, etc., can solve the problems of high price of molybdenum and restrictions on use, and achieve the effects of low cost, high cost performance and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

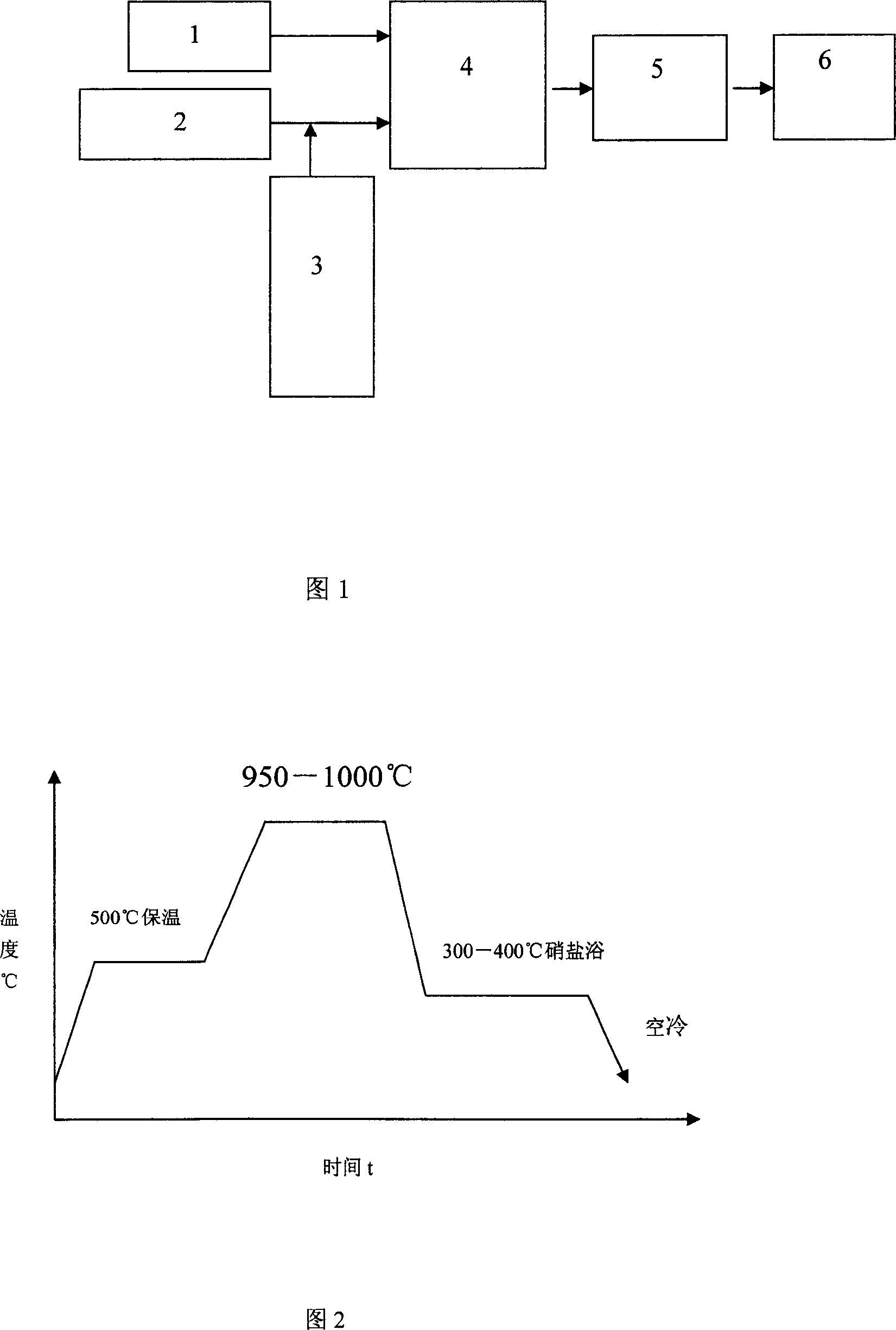

[0024] The present invention has developed a high-chromium white wear-resistant cast iron, its chemical composition (wt%) is: C: 2.6-3.0, Si: ≤ 0.6, Mn: 0.6-0.8, P ≤ 0.07, S ≤ 0.06, Cr: 16-19. Its production process is as follows:

[0025] Qualified molten iron is smelted in the intermediate frequency induction furnace according to the chemical ratio, and 0.5% rare earth silicon alloy of molten iron quality is put into the molten iron ladle. After the casting is solidified, open the box and clean it. Qualified castings are subjected to heat treatment. Heat the casting to 980°C and wait for 1.5 hours in a nitrate bath at 300-400°C. , αk≥8.5J / cm2. Compared with the conventional quenching process, that is, heating at 980°C and tempering at 250°C after air cooling, the hardness of austempering is increased by 10%, the impact toughness is increased by 40%, and the wear resistance is increased by 40%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com