Bimetal liner with flanged flange and manufacturing method of bimetal liner

A bimetallic and bushing technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of complex manufacturing process, welding stress, and failure to use normally

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The content of the present invention will be further described below in conjunction with the accompanying drawings.

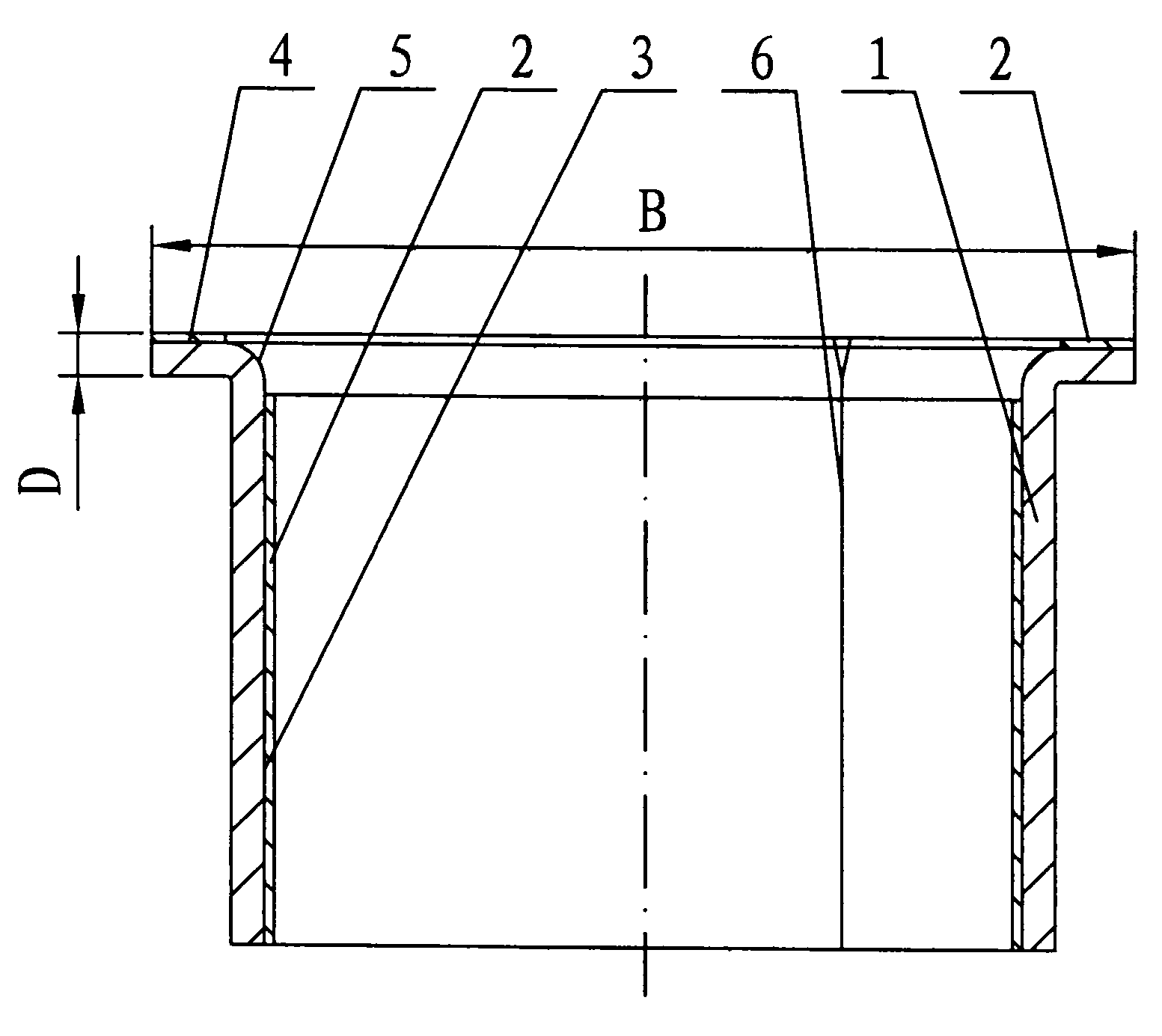

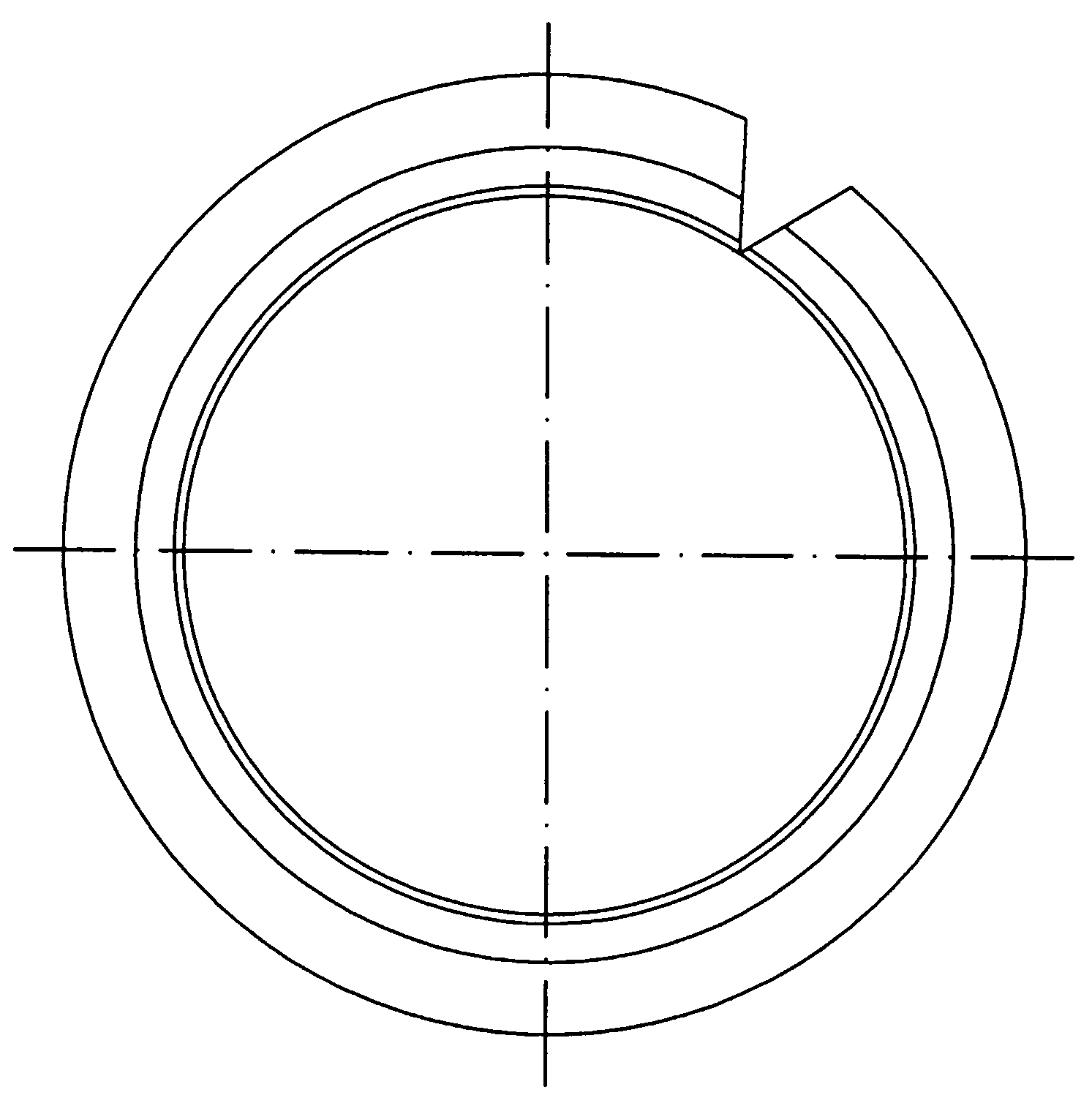

[0021] figure 1 , figure 2 It is a structural diagram of a bimetallic bush with a flanging flange. It can be seen from the figure that it includes a sleeve-shaped bimetallic bushing 3 with an outer layer of steel material 1 and an inner lining of a copper alloy layer 2. One end of the bimetallic bushing 3 is made with an everted flange 4, and the flange 4 is also a bimetallic structure of the steel material 1 and the copper alloy layer 2, and is folded between the bimetallic bushing 3 and the flange 4. There is no copper alloy layer on the outer arc surface 5 of the bend.

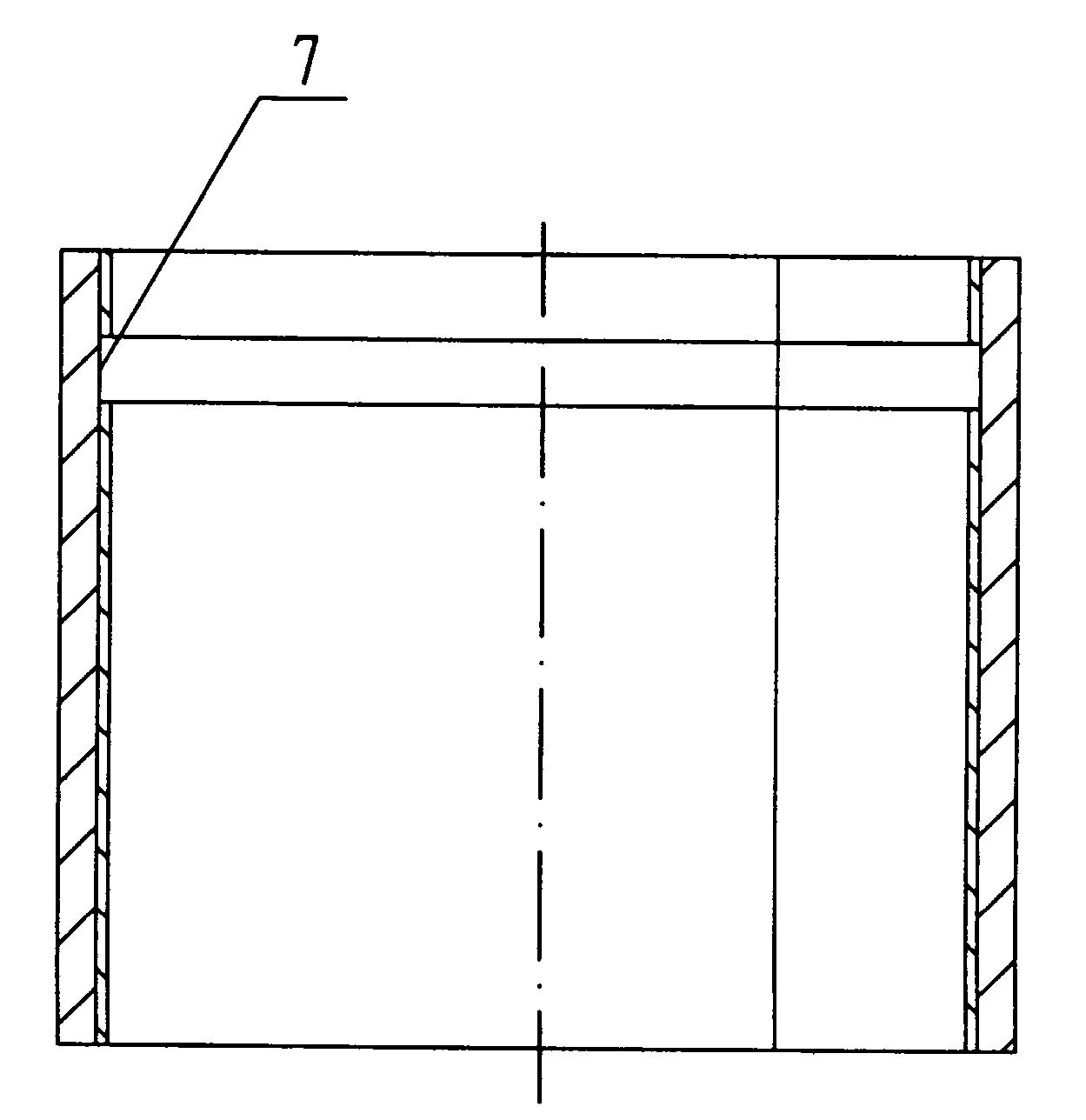

[0022] The manufacture of the bimetallic bushing with flanging flange is to roll the bimetallic sheet material sintered by steel material and copper alloy into a bushing with joint 6. Before flanging, the bimetallic bushing 3. The copper alloy layer 2 on the bending position 7 con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com