Laser three-dimensional forming method of large-size titanium-aluminum-based alloy

A technology of laser three-dimensional forming and base alloy, which is applied in the field of laser three-dimensional forming of titanium-aluminum alloy and laser three-dimensional forming of titanium-aluminum-based alloy. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

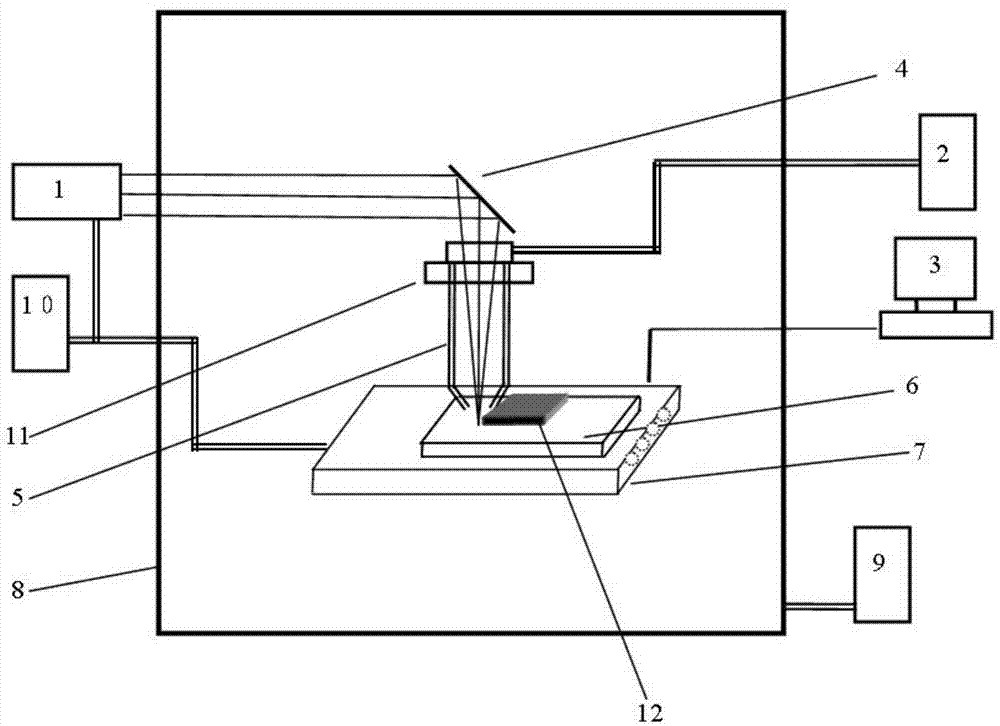

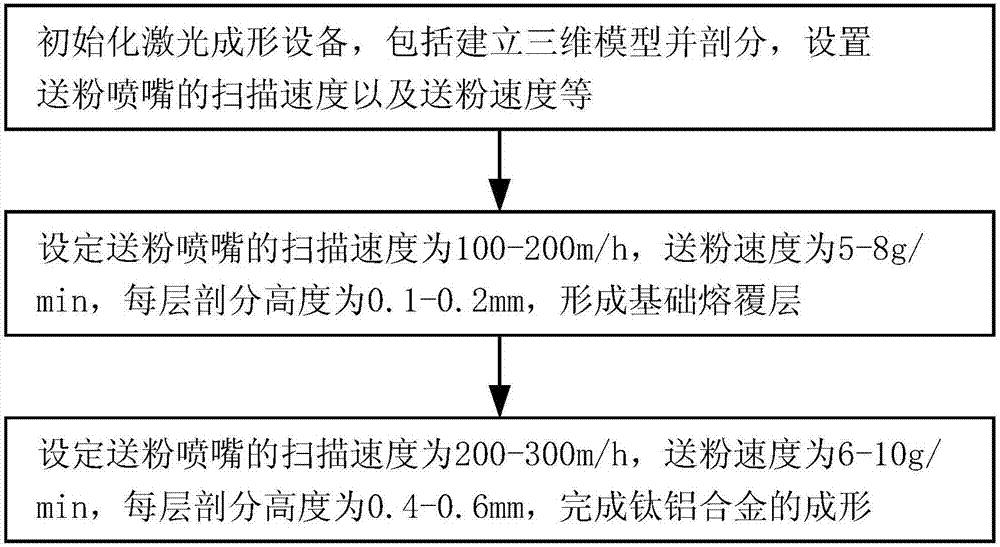

Image

Examples

Embodiment 1

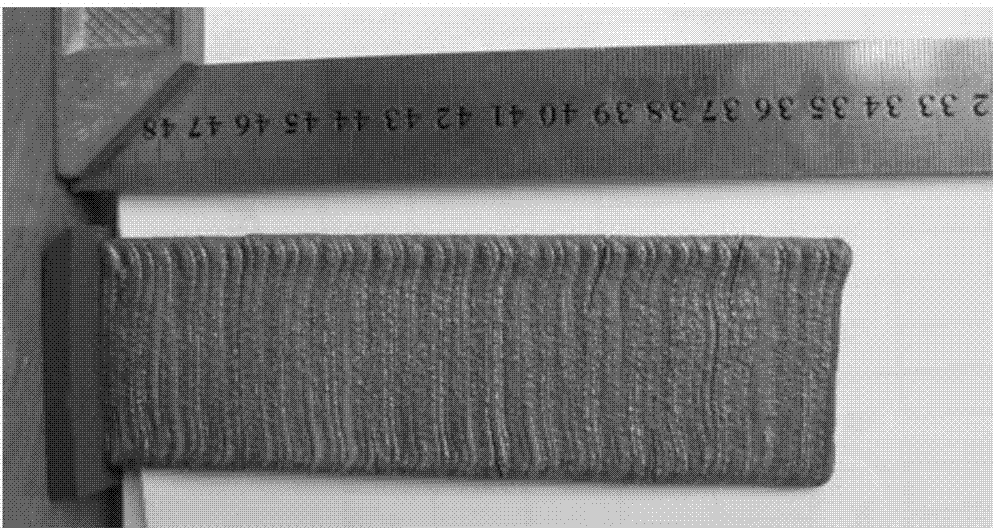

[0035] Embodiment 1: In this embodiment, a titanium-aluminum alloy sample with a height of 60 mm in width, a height of 150 mm, and a wall thickness of 3.5 mm is manufactured. The specific manufacturing steps are as follows:

[0036] 1. Select a TC4 titanium alloy plate with a thickness of about 10mm, and fix it on the machine tool with fixtures;

[0037] 2. Turn on the laser, set the laser power parameter to 700W, high-purity CO 2 , high-purity He, high-purity N 2 The pressure is adjusted to about 0.5MPa, and the cooling water flow is about 20L / min;

[0038] 3. Put the titanium-aluminum alloy powder into the powder feeder;

[0039] 4. Use UG software to build a model and use the subdivision software that comes with the forming equipment to subdivide the 3D model. The subdivision height of each layer is set to 0.1mm, and the scanning speed of the powder feeding nozzle is set to 100m / h. Powder speed 5g / min;

[0040] 5. When cladding 10 layers, use the subdivision software t...

Embodiment 2

[0043] Embodiment 2: In this embodiment, a titanium-aluminum alloy sample with a height of 40 mm in width, a height of 50 mm, and a wall thickness of 10 mm is produced. The specific manufacturing steps are as follows:

[0044] 1. Select a TC4 titanium alloy plate with a thickness of about 10mm, and fix it on the machine tool with fixtures;

[0045] 2. Turn on the laser, set the laser power parameter to 1000W, high-purity CO 2 , high-purity He, high-purity N 2 The pressure is adjusted to about 0.5MPa, and the cooling water flow is about 20L / min;

[0046] 3. Put the titanium-aluminum alloy powder into the powder feeder;

[0047] 4. Use UG software to build a model and use the subdivision software that comes with the forming equipment to subdivide the 3D model. The subdivision height of each layer is set to 0.1mm, and the scanning speed of the powder feeding nozzle is set to 100m / h. Powder speed 5g / min;

[0048] 5. When cladding 10 layers, use the subdivision software that c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com