Metal layer, paper pot and manufacturing method of paper pot

A manufacturing method and metal layer technology, applied in the fields of application, cooking utensil structure, kitchen utensils, etc., can solve the problems of insufficient ductility, flexibility and strength of the metal layer, poor formability of the metal layer, poor thermal conductivity of the metal layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

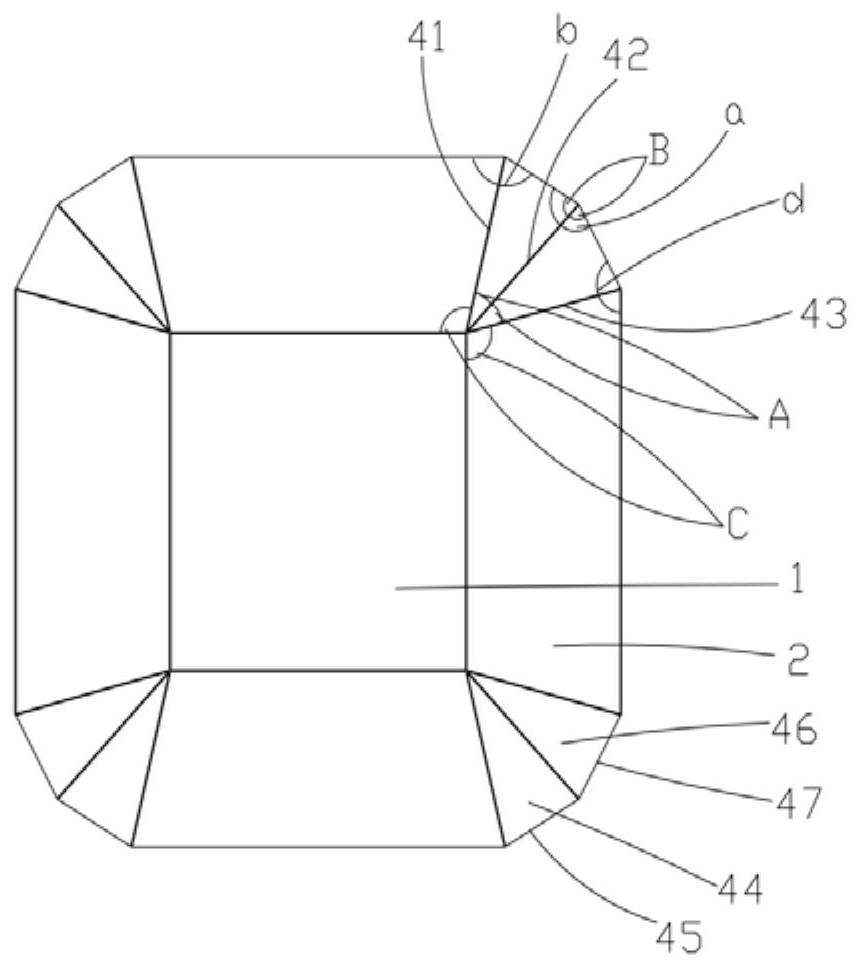

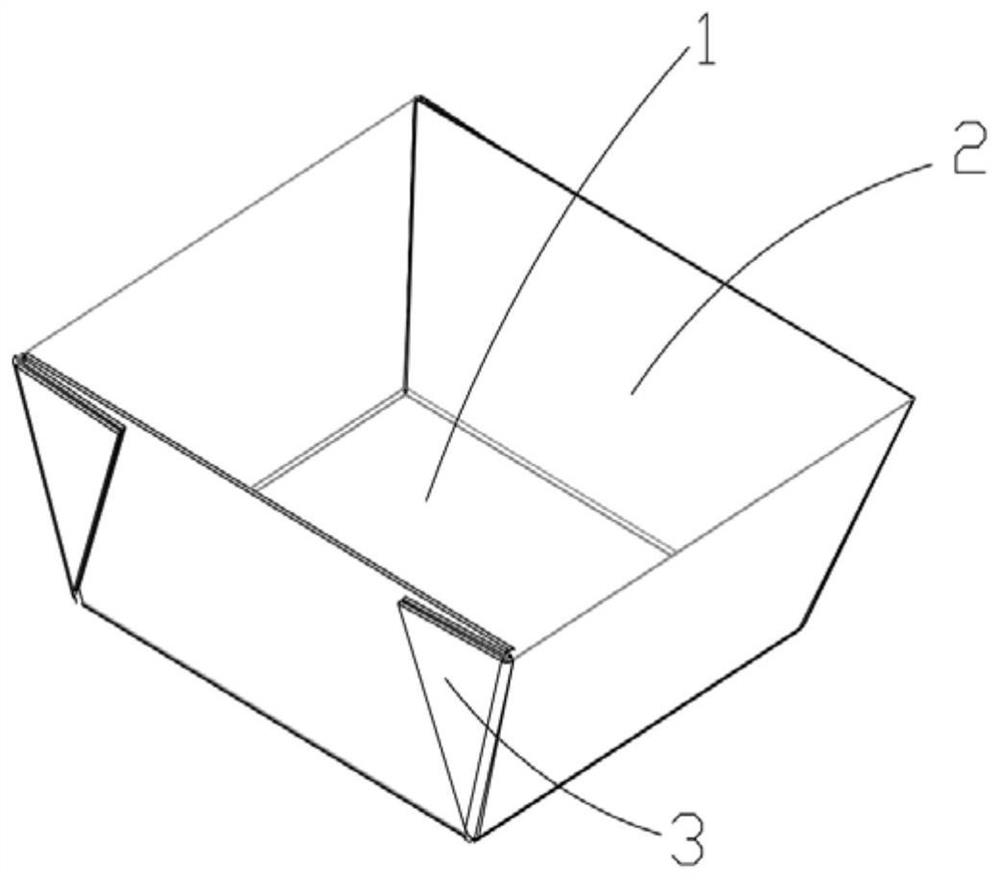

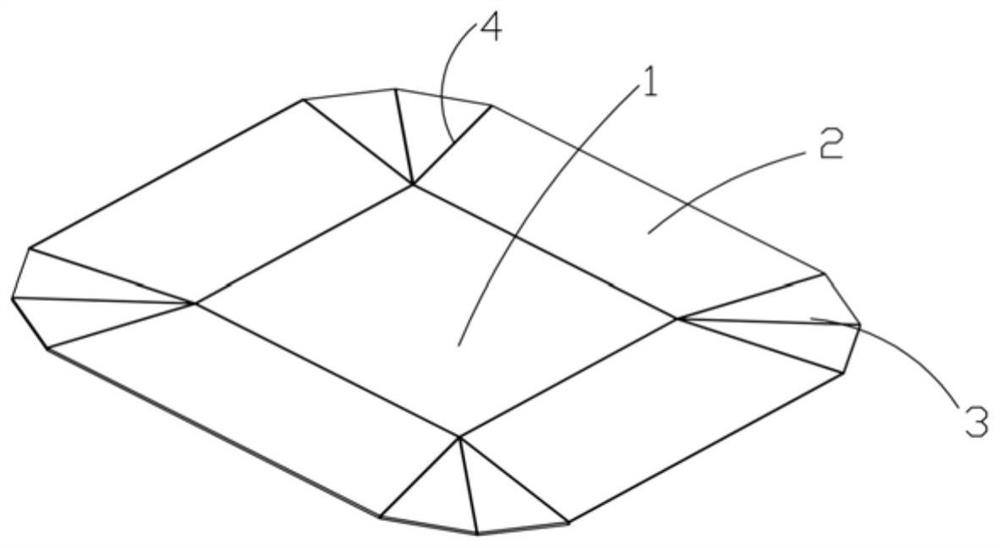

Embodiment Construction

[0035] A metal layer provided by an embodiment of the present invention includes Al: 80%-89%, Fe: 0.4%-0.7%, in terms of mass percentage. The metal layer, the resin layer, and the paper layer together form a composite layer, which is used to make a paper pot. The paper pot is used for matching with an induction cooker, or the paper pot is used to generate electromagnetic waves for magnetic field induction current (also known as eddy current). The heating principle is used in conjunction with the heating equipment. Since the metal layer, the resin layer, and the paper layer constitute the composite layer, when the paper pot is formed by stamping, in order to suppress the generation of flange wrinkles, a high wrinkle pressure is usually applied. When high crease pressure is loaded, the stamping load becomes large due to the high friction between the two sides of the mold and the paper pot material. Therefore, in order to carry out deeper forming during stamping and forming of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com