Bell-type heating resistance furnace system

A heating resistance, bell jar type technology, applied in the direction of heat treatment furnace, furnace, furnace type, etc., can solve the problems that cannot meet the production and processing, achieve the effect of improving heat treatment effect, avoiding uneven hardness of products, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with drawings and embodiments.

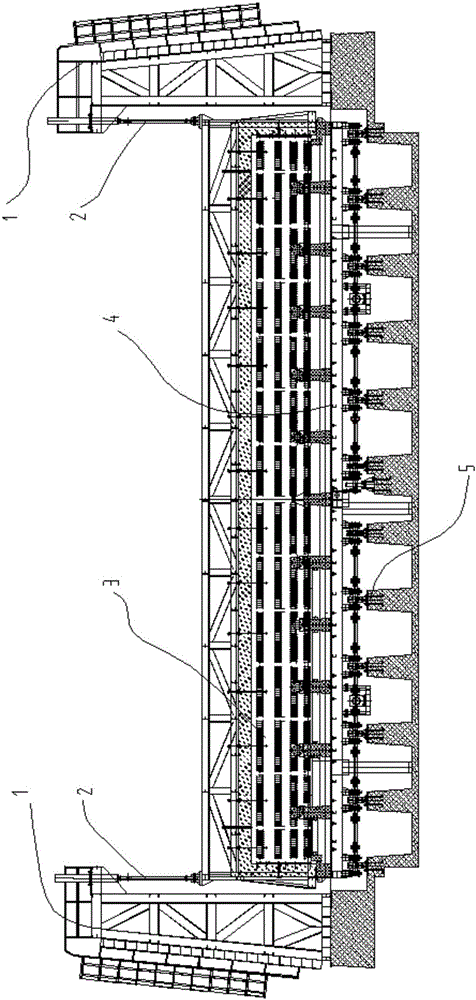

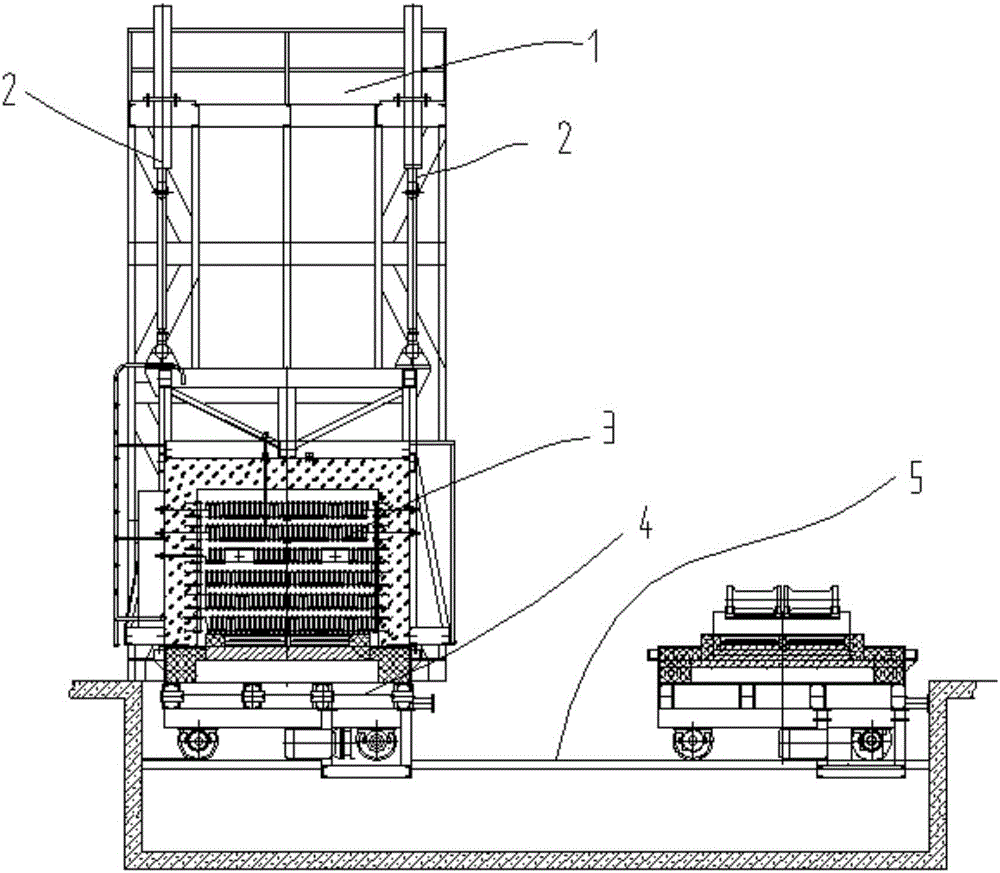

[0028] as attached figure 1 - attached Figure 7 A bell-type heating resistance furnace system shown includes two oppositely arranged support frames 1, and a heating mantle 3 capable of moving up and down is arranged between the two support frames 1, and each of the support frames 1 has At least one hydraulic cylinder 2 is connected, the fixed end of the hydraulic cylinder 2 is fixedly connected with the support frame 1, and its movable end is fixedly connected with the heating cover 3, and a carrying trolley 4 capable of moving back and forth is arranged under the heating cover 3, A track 5 is provided at the lower position between the two support frames 1 , and the carrying trolley 4 moves forward and backward on the track 5 .

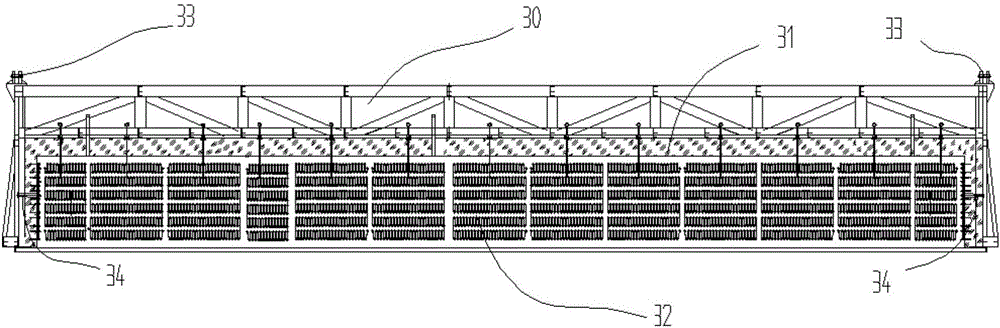

[0029] from image 3 with Figure 4 It can be seen that the heating mantle 3 includes a heating mantle skeleton 30, and an insulator 31 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com