Color emulsified asphalt and preparation method thereof

A technology of colored asphalt and emulsified asphalt, which is applied in the field of composite modified colored emulsified asphalt formula and its preparation, can solve the problems of low softening point of emulsified asphalt, inability to use black asphalt, and high cost of colored pavement, and achieve excellent road performance and improved High temperature stability of the seal layer and its low temperature crack resistance, the effect of improving high temperature stability and low temperature crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

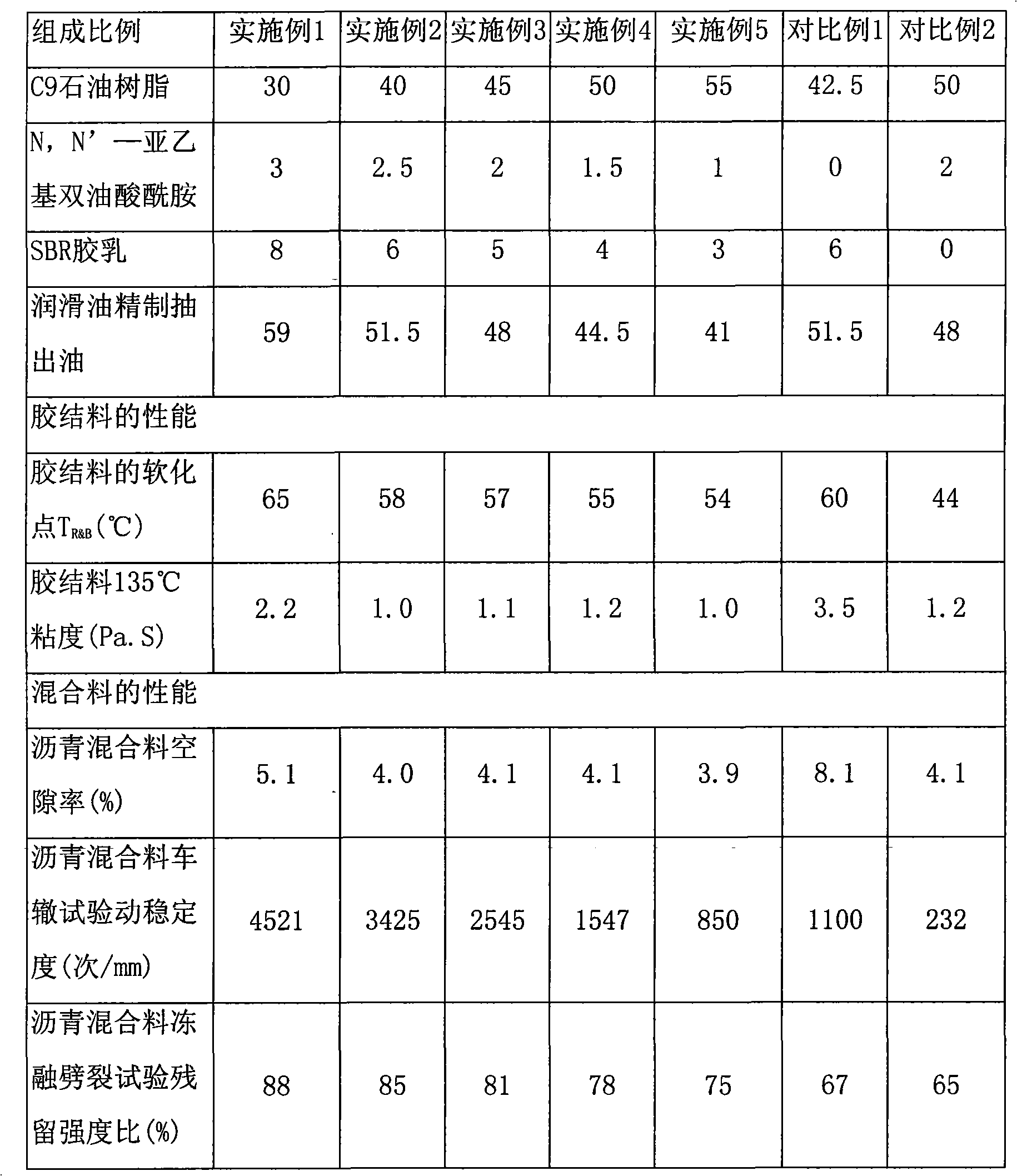

Embodiment 1~5

[0044] Raw materials used:

[0045] A lubricating oil refined extraction oil, produced by Taiwan CNPC Co., Ltd., trade name: Guoguang brand rubber softening oil, viscosity at 40°C 3.1Pa.S, flash point: 253°C, aromatic content: 74.7wt%, density at 15°C: 0.94 g / cm3.

[0046] B C9 petroleum resin, Korea Kolon company product, trade name: Hikotack P140, softening point 145 ℃, average molecular weight (GPC method) 2200

[0047] C N, N'-Ethylene bisoleic acid amide, produced by Jiangxi Weike Oleochemical Co., Ltd.

[0048] D modifier SBR latex is cationic styrene-butadiene latex, PC1468 produced by U.S. MeadWestvaco company

[0049] Heat the extracted lubricating oil to 175°C, then add C9 petroleum resin, N, N'-ethylene bisoleic acid amide and SBR latex, and stir with a stirrer at a speed of 200 rpm for 60 minutes, that is The finished cement is prepared. The specific composition ratio (percentage by weight) and the results of the cementitious material detected by the detection ...

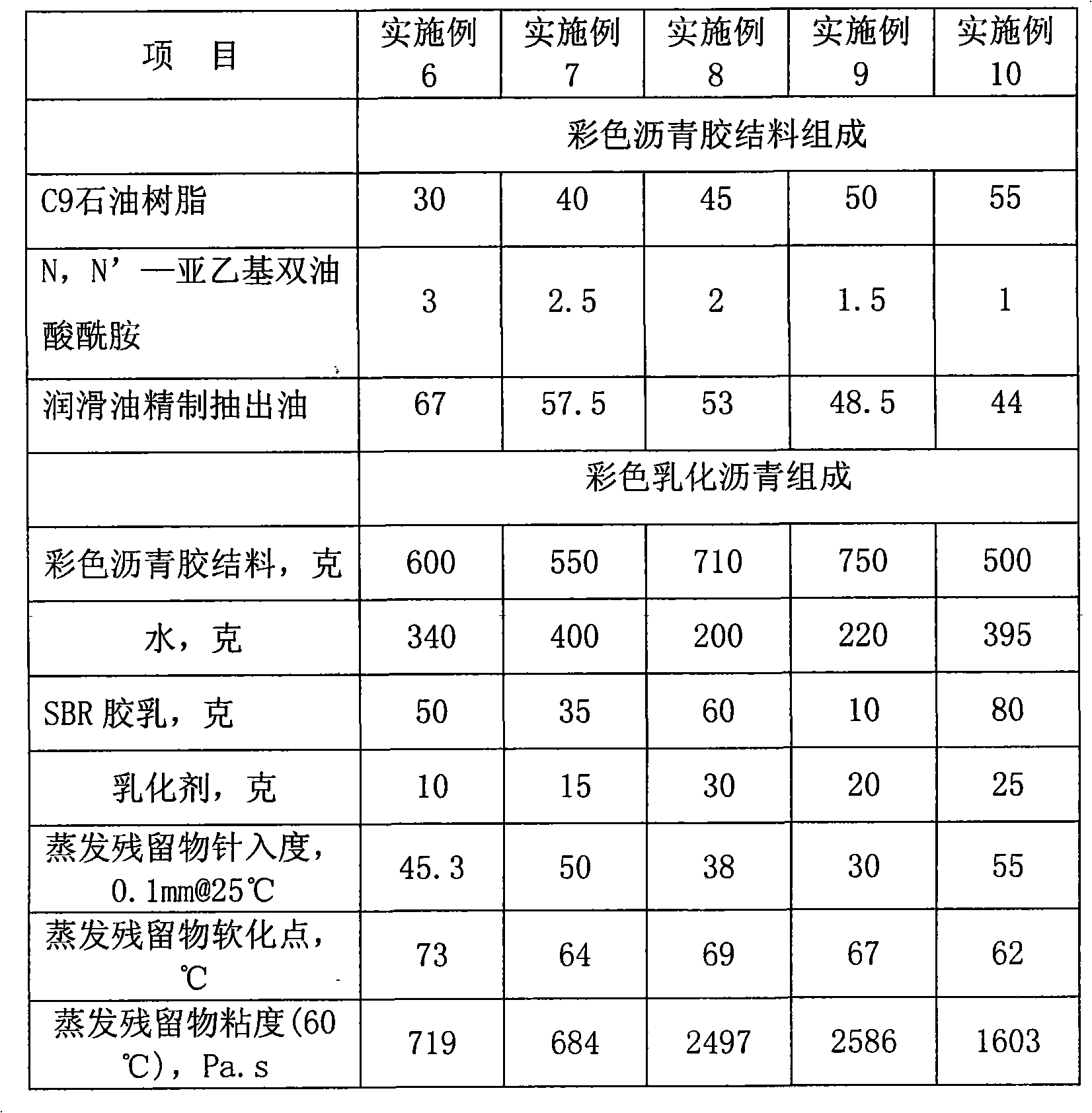

Embodiment 6-10

[0056] Prepare the colored asphalt binder according to the ratio in Table 2, then heat the colored asphalt binder to 125°C to make it completely melted, and stir it to make it evenly mixed. Take the corresponding water, add the MQK-1D emulsifier produced by MeadWestvaco Co., Ltd., and the corresponding modifier SBR latex to this water, and add hydrochloric acid solution to adjust the acid value, so that the solution pH = 2.1, stir evenly, and heat up to 60 ° C, color The composition of emulsified asphalt is shown in Table 2. Mix the colored asphalt binder and soap solution prepared above and pass through the colloid mill for 1 to 3 times. The properties are shown in Table 2.

[0057] Table 2

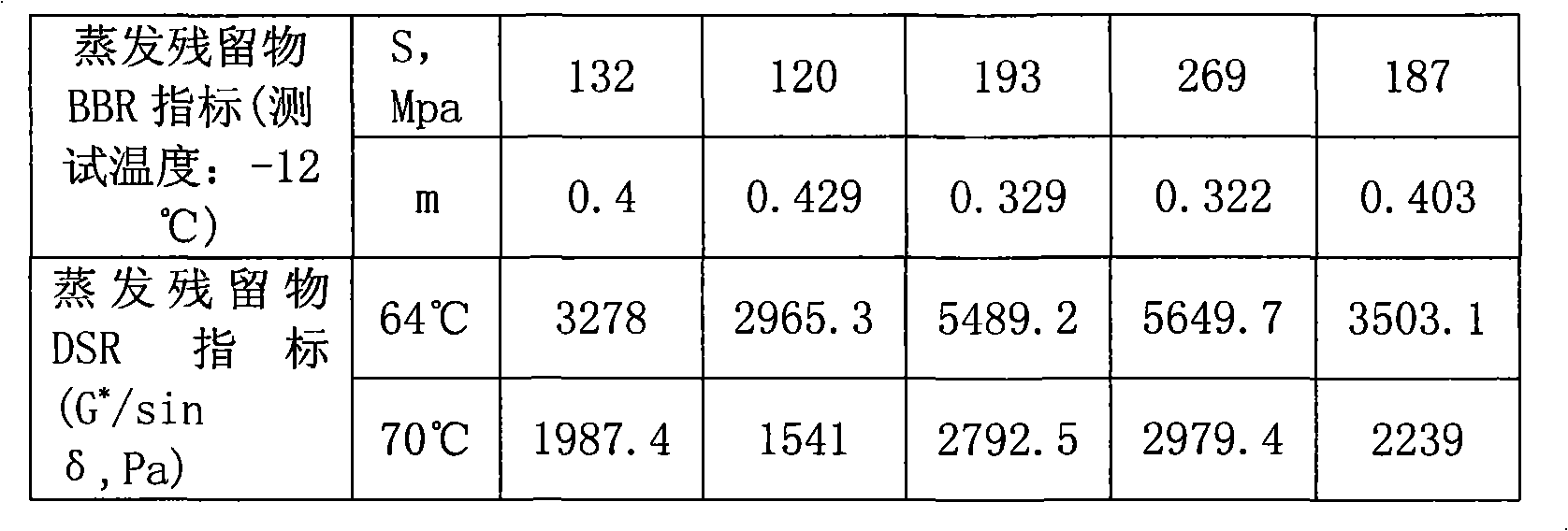

[0058]

[0059]

[0060] Test method: 1. Softening point of evaporation residue, °C: ASTM D36, China T0606-2000

[0061] 2. Viscosity of evaporation residue, Pa.s: China T0625-2000

[0062] 3. Evaporation residue BBR index S, Mpa, m: AASHTO: TP1-98

[0063] 4. Evaporation resid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Flash point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com