Conductive paste and solar battery cell using said conductive paste

A technology of solar cells and conductivity, applied to electrical components, conductive materials dispersed in non-conductive inorganic materials, semiconductor devices, etc., can solve the problem of conductive paste containing lead components, etc., and achieve high BSF and good adhesion sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

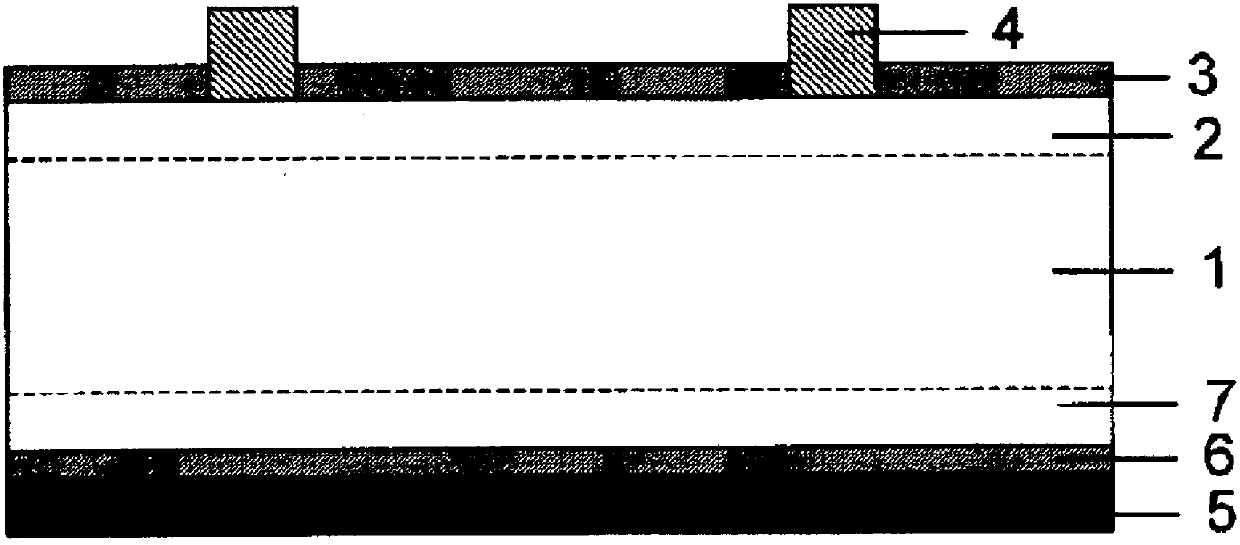

Image

Examples

Embodiment

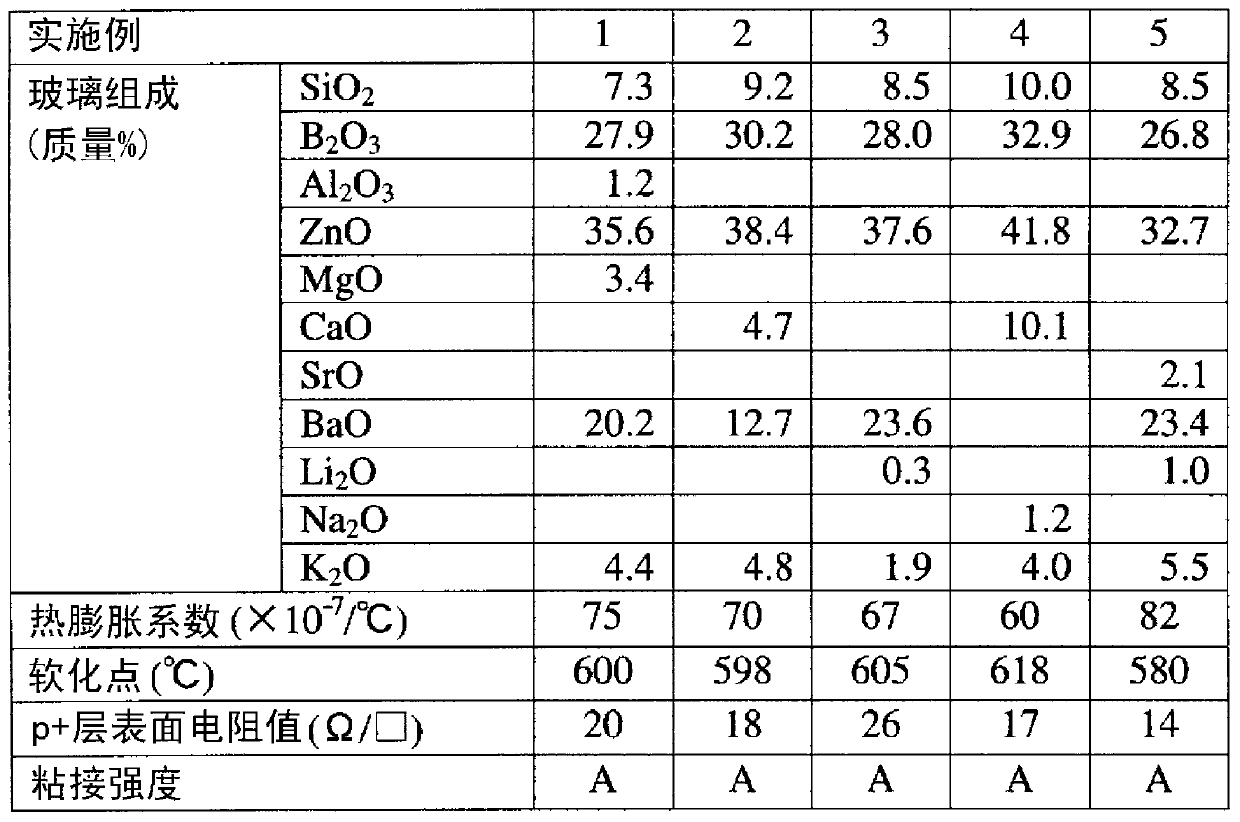

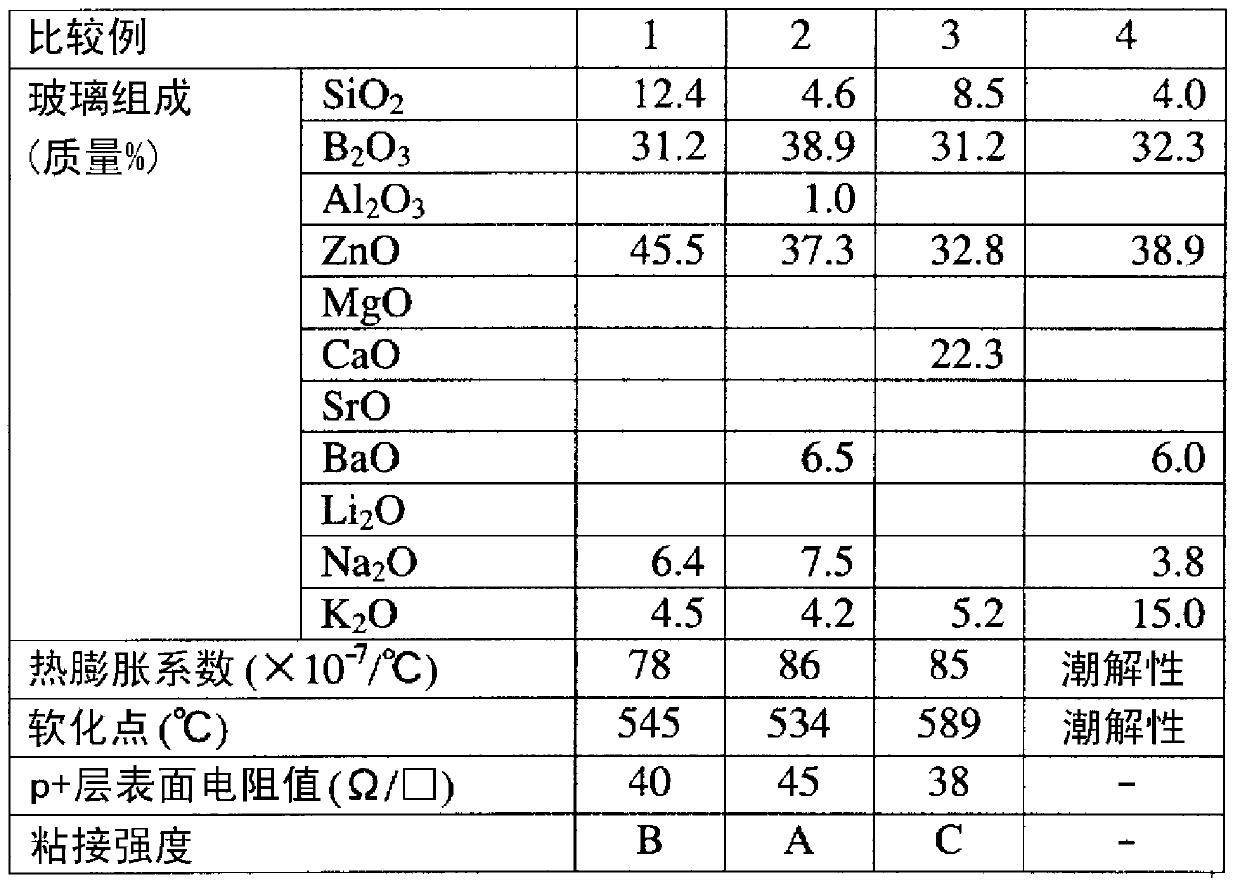

[0033]Hereinafter, it demonstrates based on an Example.

[0034] (conductive paste)

[0035] First, with regard to glass powder, various inorganic raw materials were weighed and mixed so as to have a specific composition described in the examples, to prepare a raw material masterbatch. Put this master batch of raw materials into a platinum crucible, heat and melt it in an electric heating furnace at 1000-1300°C for 1-2 hours, and obtain the compositions shown in Examples 1-5 in Table 1 and Comparative Examples 1-4 in Table 2 glass. A part of the glass is poured into the mold to form a block, which is used for the measurement of thermal physical properties (thermal expansion coefficient, softening point). The remaining glass is formed into flakes by a rapid cooling twin-roll forming machine, and granulated by a crushing device into a powder with an average particle size of 1-4 μm and a maximum particle size of less than 10 μm.

[0036] In addition, the said softening point w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com