Potassium decaborate fertilizer and method for producing the same

A production method and technology of potassium borate, applied in the directions of potash fertilizer, inorganic fertilizer, fertilizer mixture, etc., can solve the problems of low absorption and utilization rate of boron and potassium, high product price, complicated production process, etc., and achieve good ecological benefits and moderate pH. , Obvious effect of fertilizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

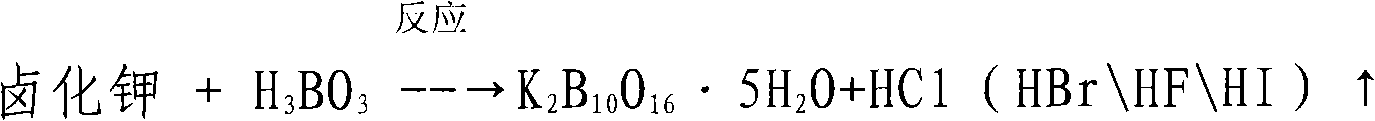

Method used

Image

Examples

Embodiment 1

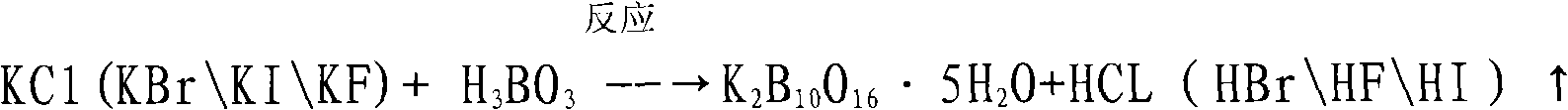

[0029] ①Add 60 parts by weight of water to the reactor, heat to 60°C, then put 25 parts by weight of potassium chloride in the reactor, after the violent reaction stops, slowly add 55 parts by weight of boric acid, and heat while stirring until complete Dissolved; hydrogen chloride gas enters the recovery device through the air duct for recovery

[0030]

[0031] ② Add 1 part by weight of dodecylbenzenesulfonic acid to the product obtained by the above method and stir evenly, keeping the temperature at 80-100°C;

[0032] ③The liquid is sent to a high-speed centrifugal dryer for drying, the inlet temperature is controlled to be 400-530°C, the outlet temperature is 140-180°C, cooled to normal temperature, and the potassium decaborate of the present invention is obtained.

[0033] The powder product produced above is divided into bags according to different weights, which is the high-content instant potassium decaborate fertilizer of the present invention (pure boron ≥ 18.3%, ...

Embodiment 2

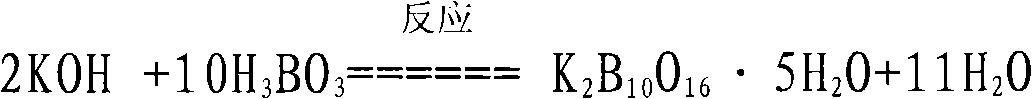

[0035] (1) Add 60 parts by weight of water in the reactor, heat to 60°C, then place 25 parts by weight of potassium hydroxide in the reactor, after the violent reaction stops, slowly add 55 parts by weight of boric acid, and heat while stirring, until completely dissolved;

[0036]

[0037] (2) Add 0.1 parts by weight of calcium dodecylbenzenesulfonate to the product obtained by the above method and stir evenly, keeping the temperature at 80-100°C;

[0038] ③The above-mentioned substances are sent to a high-speed centrifugal dryer for drying, the inlet temperature is controlled to be 400-530° C., the outlet temperature is 140-180° C., and cooled to normal temperature to obtain potassium decaborate of the present invention.

[0039] The powder product produced above is divided into bags according to different weights, which is the high-content instant potassium decaborate fertilizer of the present invention (pure boron ≥ 18.3%, available potassium ≥ 22.4%)

[0040] There ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com