Patents

Literature

30results about How to "No touch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

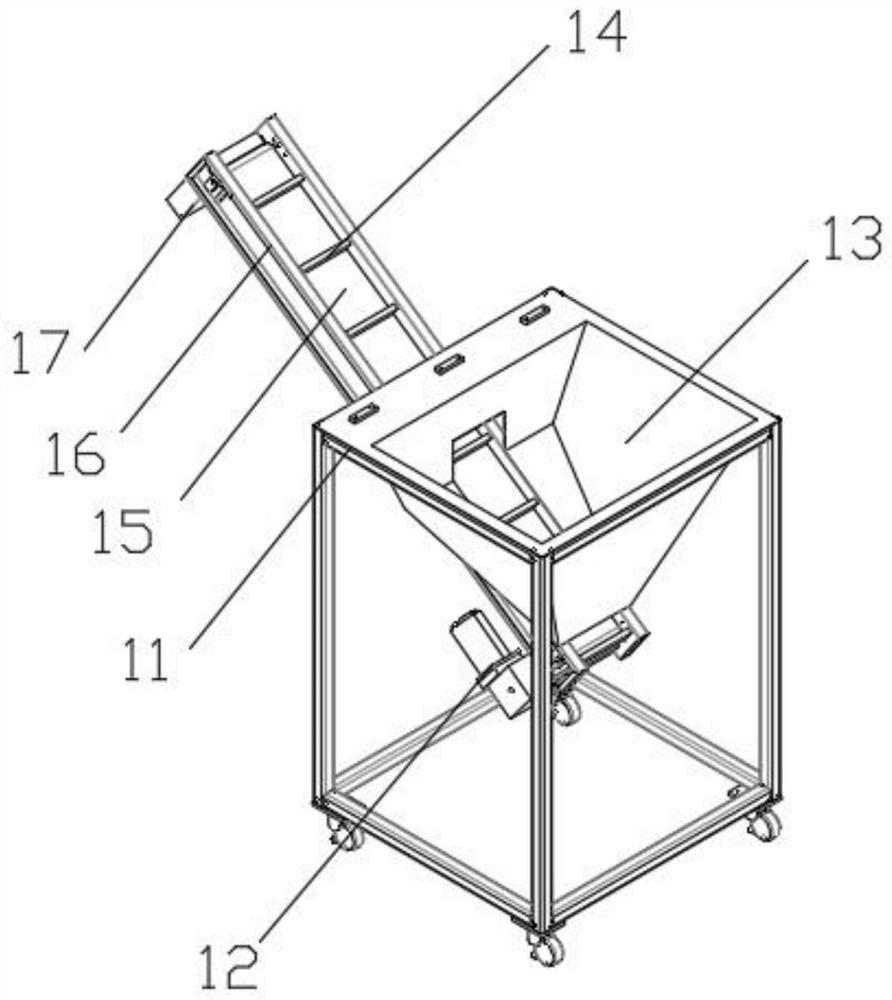

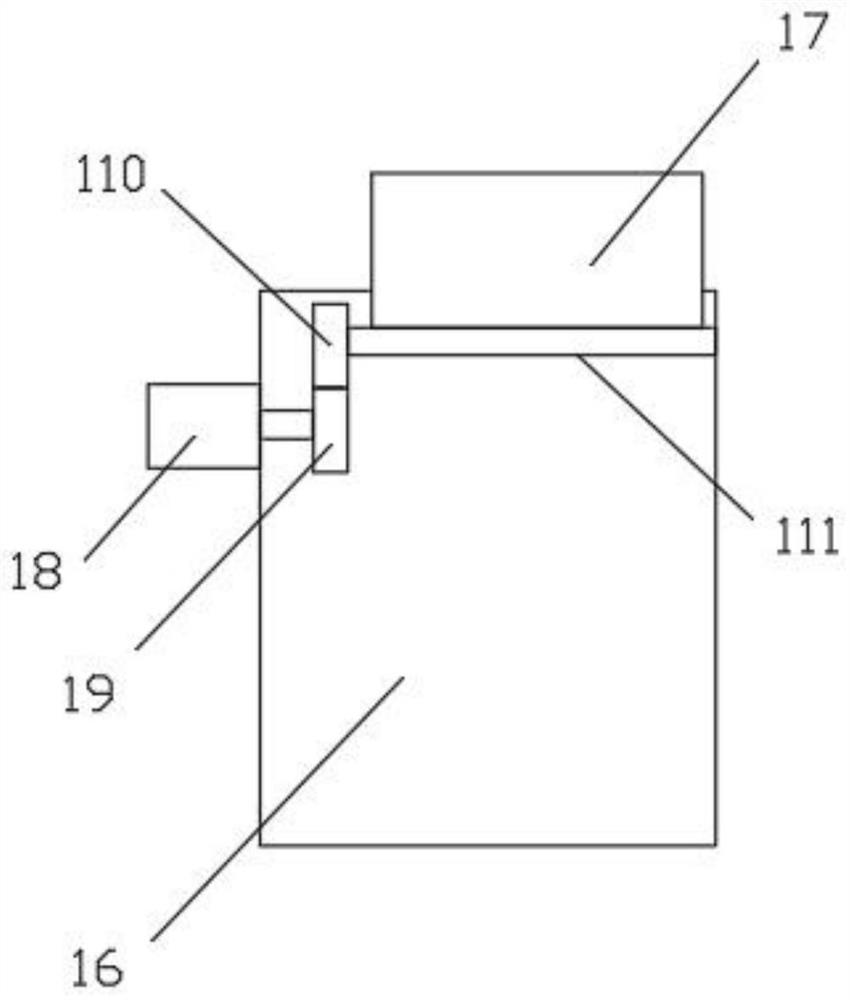

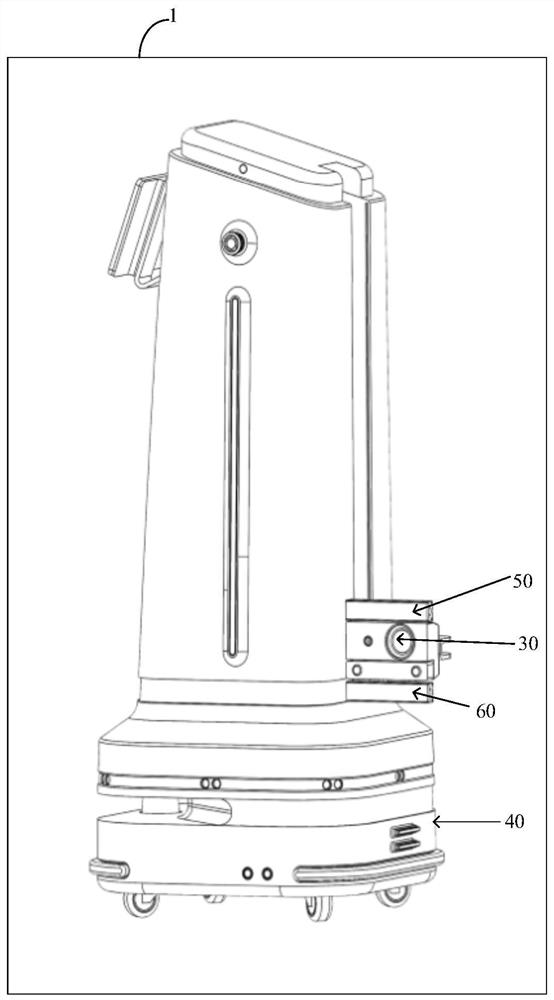

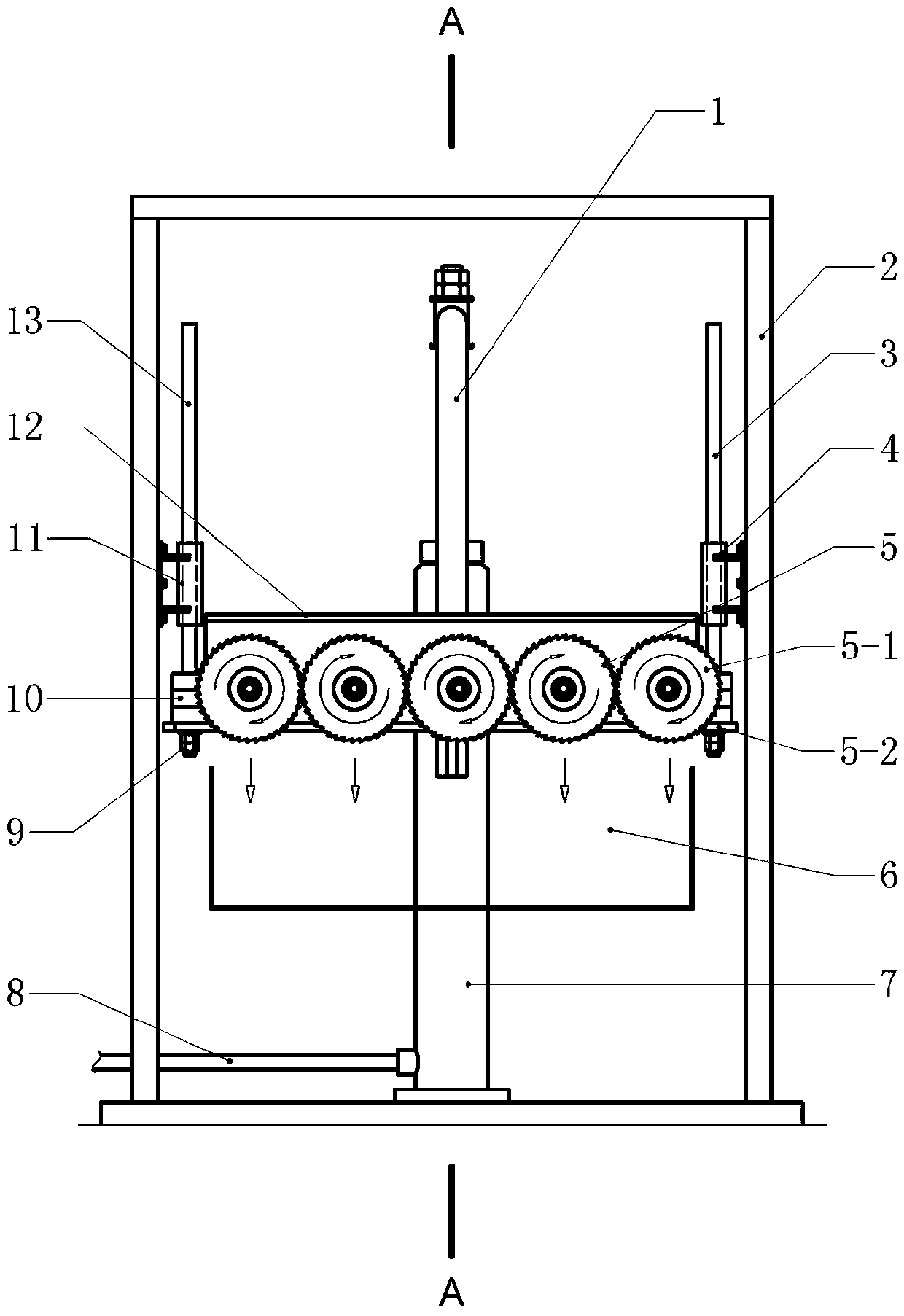

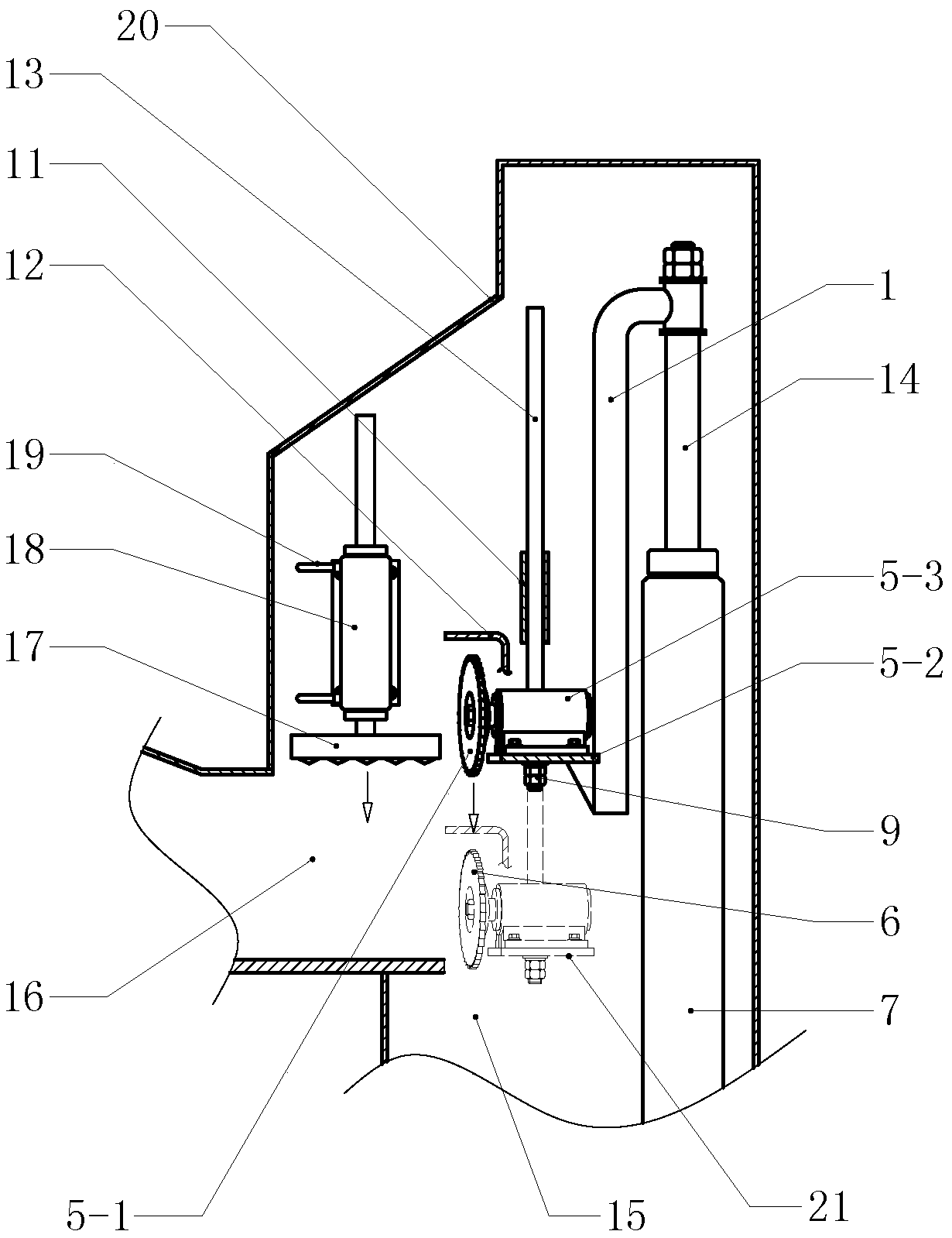

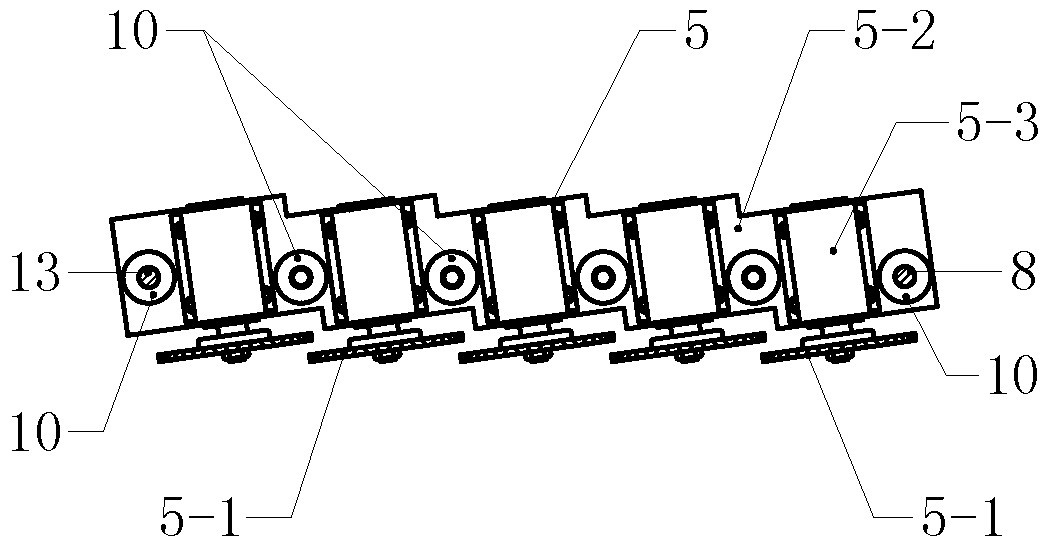

Control device of lifting platform for detection device and detection device

ActiveCN111120827AAvoid touchingAddressed issues with hitting the ceilingTelevision system detailsSafety arrangmentsComputer hardwareElectric machinery

Owner:JD DIGITS HAIYI INFORMATION TECHNOLOGY CO LTD

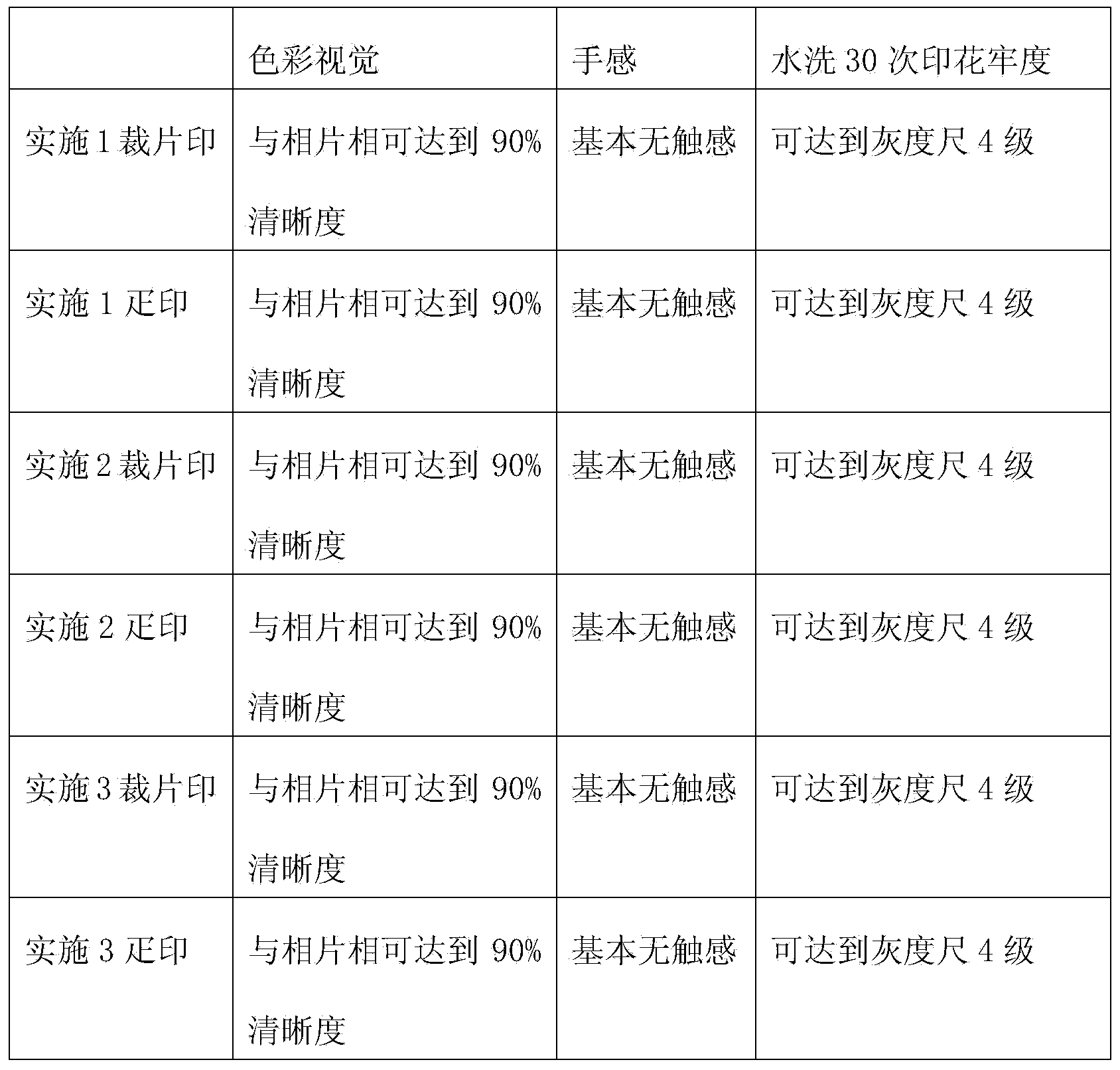

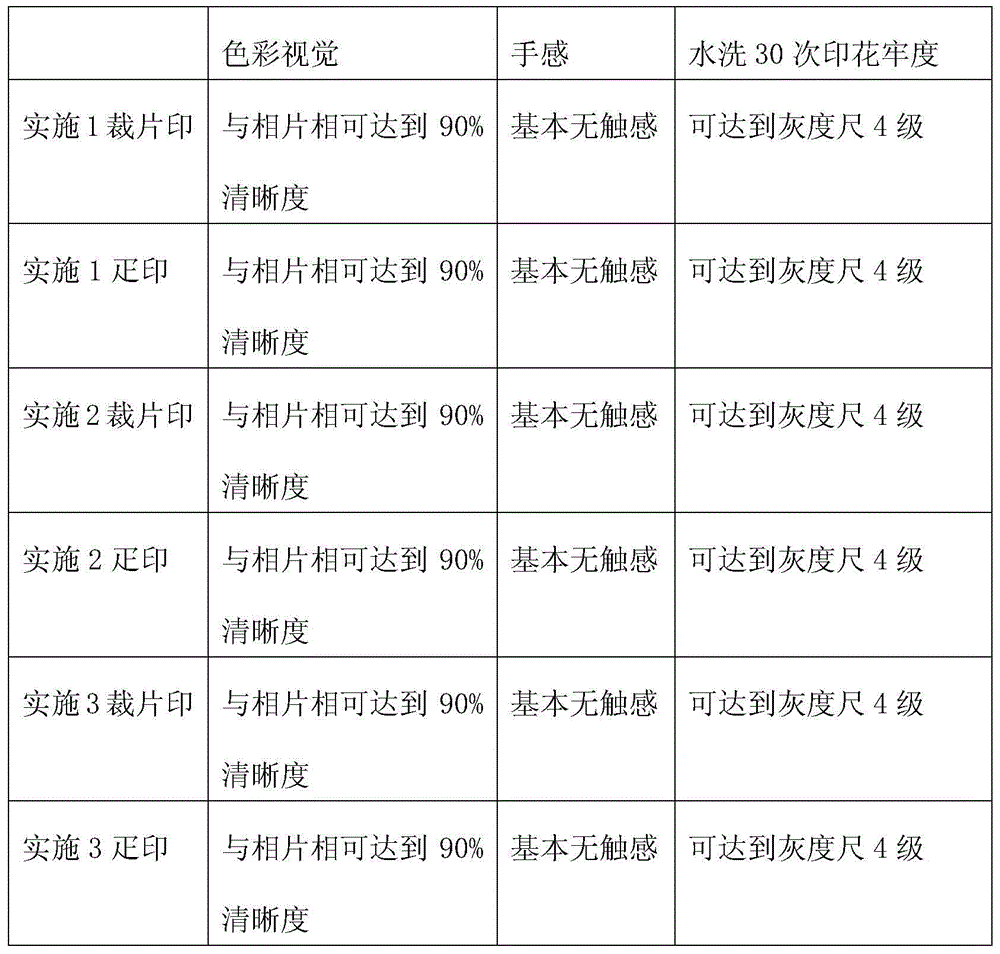

Sublimation transfer printing process for natural fabrics or rayon

InactiveCN103898778ANo touchSoft touchTransfer printing processVegetal fibresPulp and paper industryPre treatment

The invention discloses a sublimation transfer printing process for natural fabrics or rayon. The process comprises the following steps: printing a layer of surface treating agents on cloth, and drying; and printing transfer paper coated with patterns to the cloth printed with the surface treating agents for cooling under the conditions of the temperature of 180-220 DEG C, the pressure of 6-15KG per square inch and the time of 15-20 seconds, and cooling. According to the sublimation transfer printing process, the color and the cloth are totally natural in the process of printing natural fibers, rayon and Leisel cloth, the cloth is non-tactile, is extremely soft in handfeel and vivid in effect, is just like a photo, is almost as vivid as colored rough sketch, is basically not discolored after washing and is also bright and beautiful. In the pretreatment link, only the surface treating agents are sprayed or printed, washing is not needed, only drying is needed, and any damage to the environment is avoided.

Owner:中山市粤漳科技有限公司

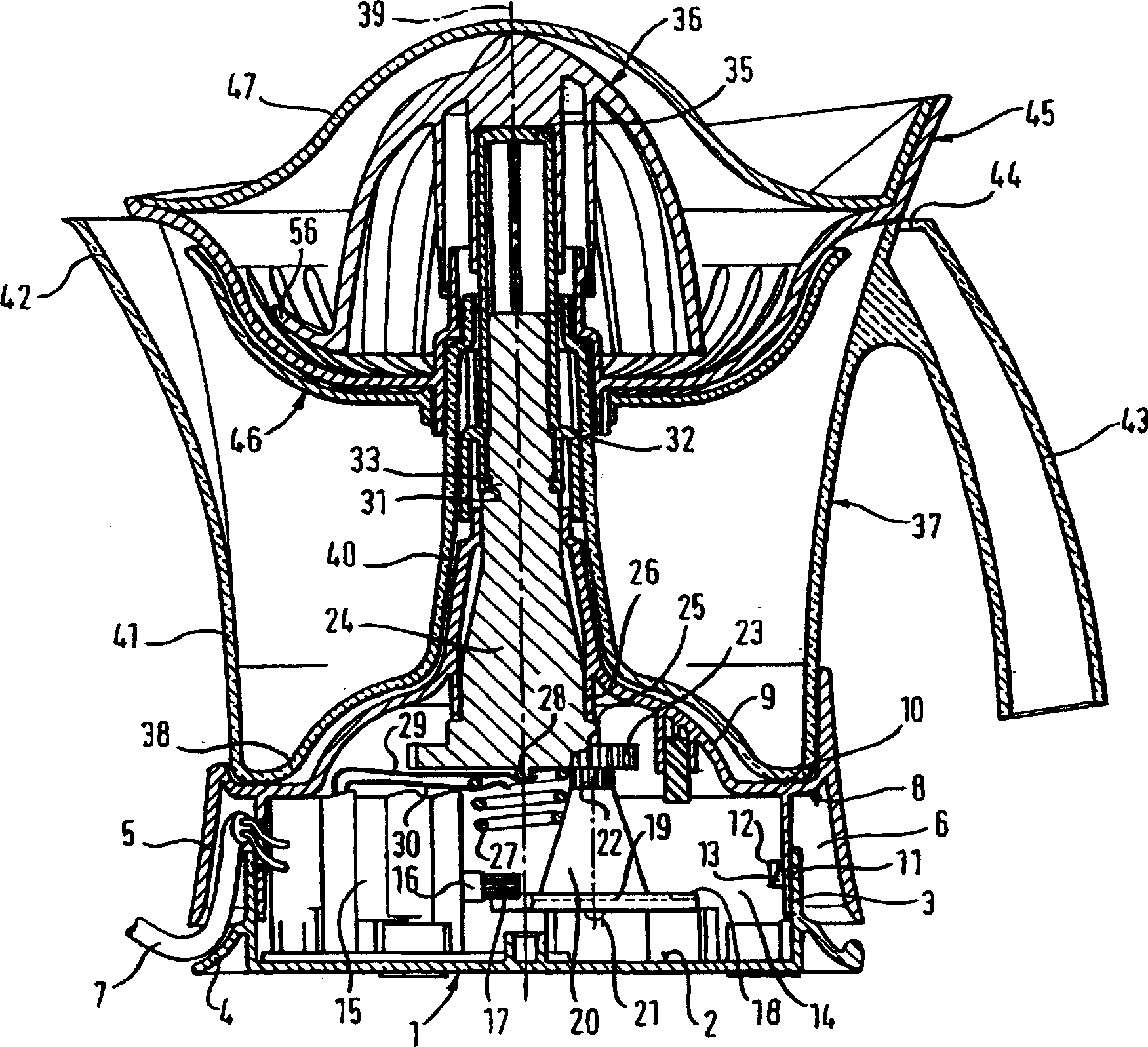

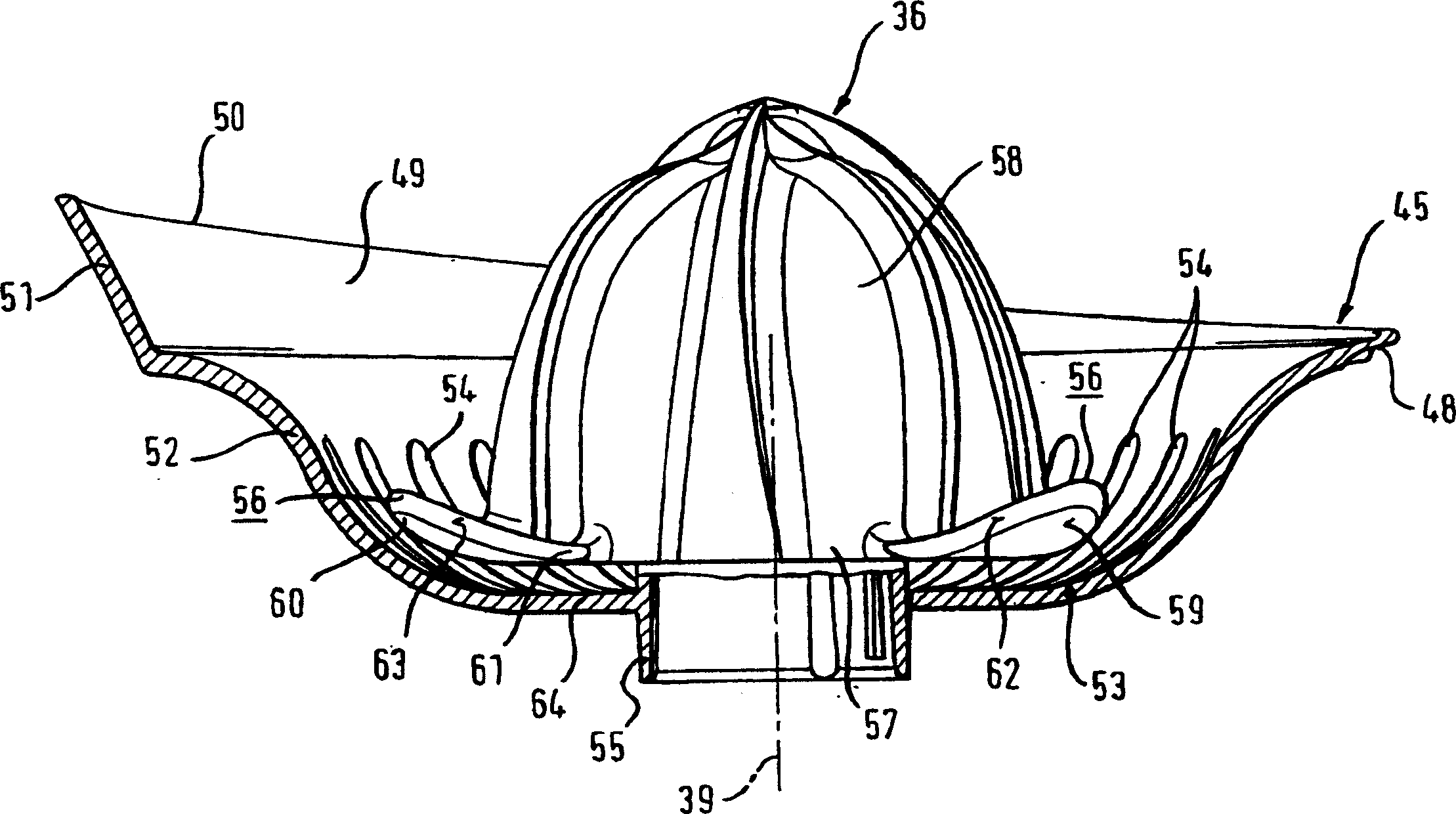

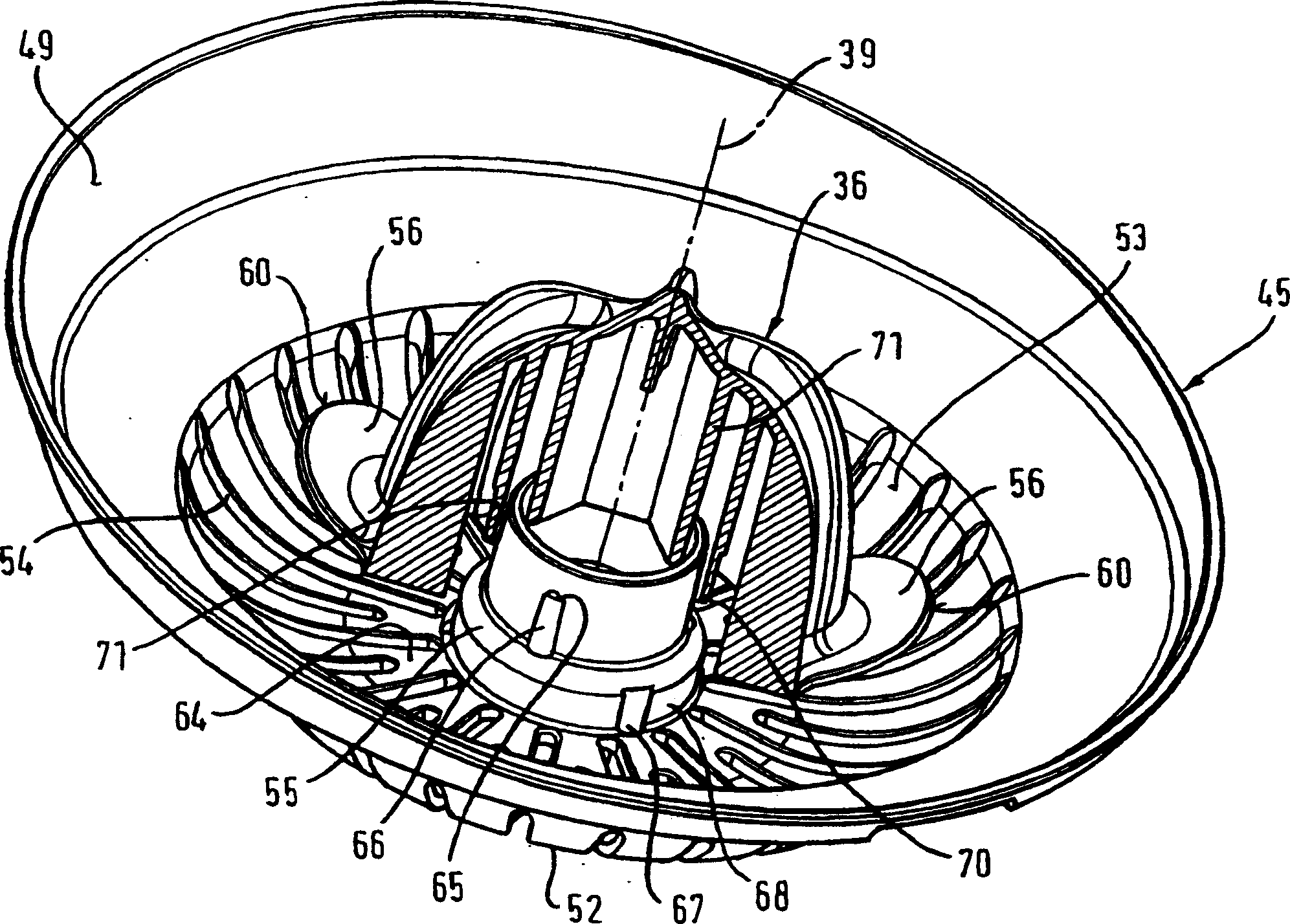

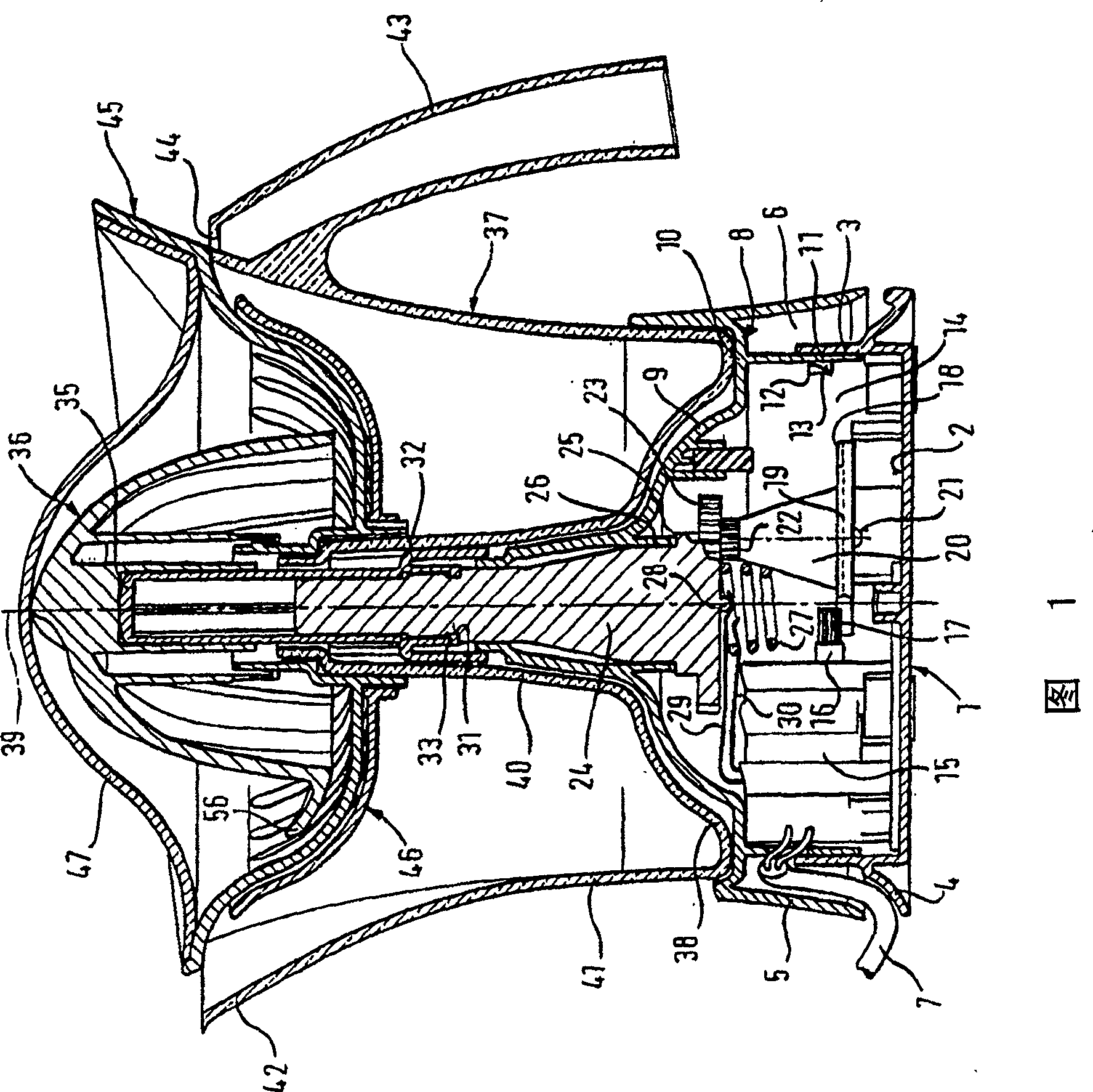

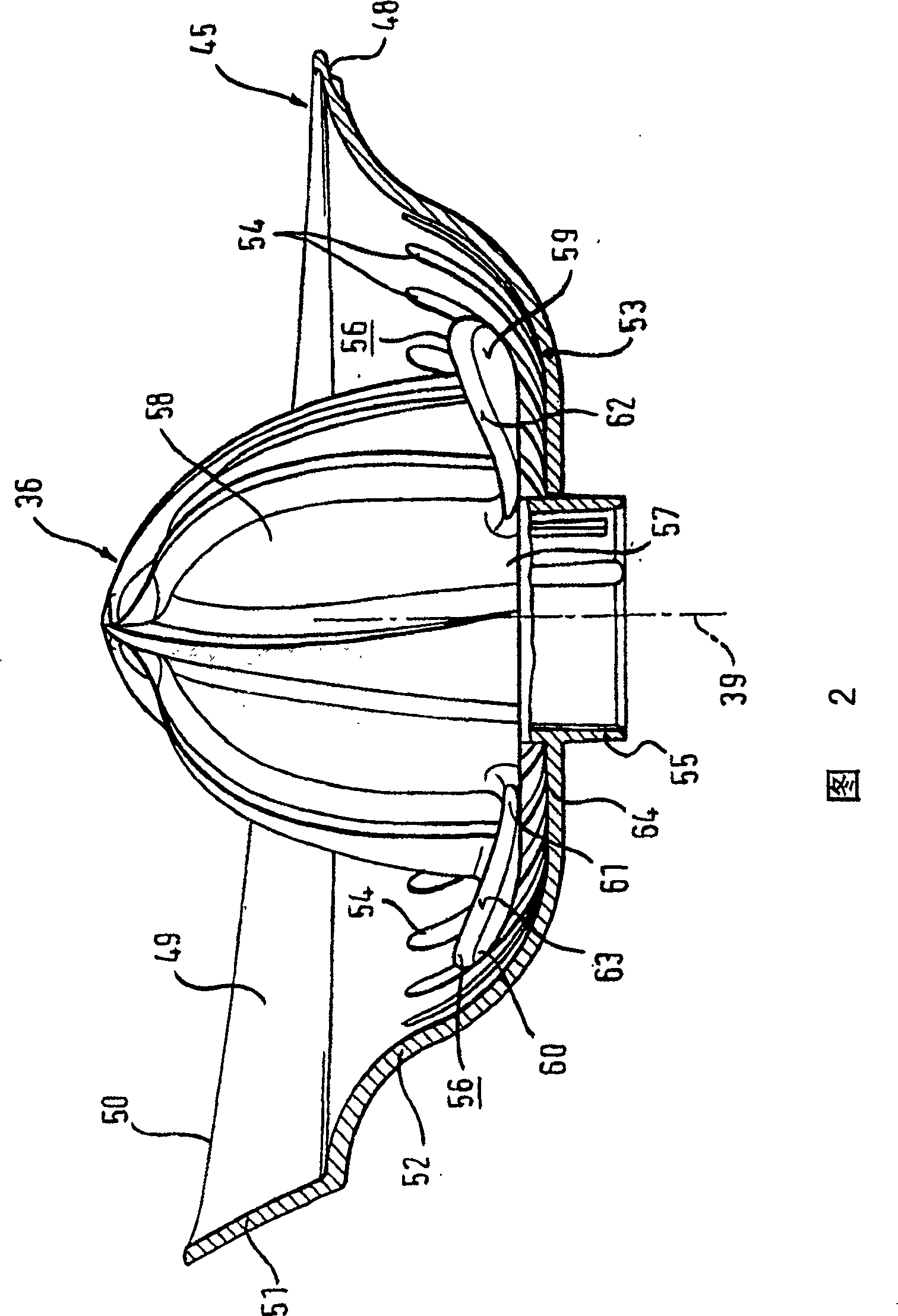

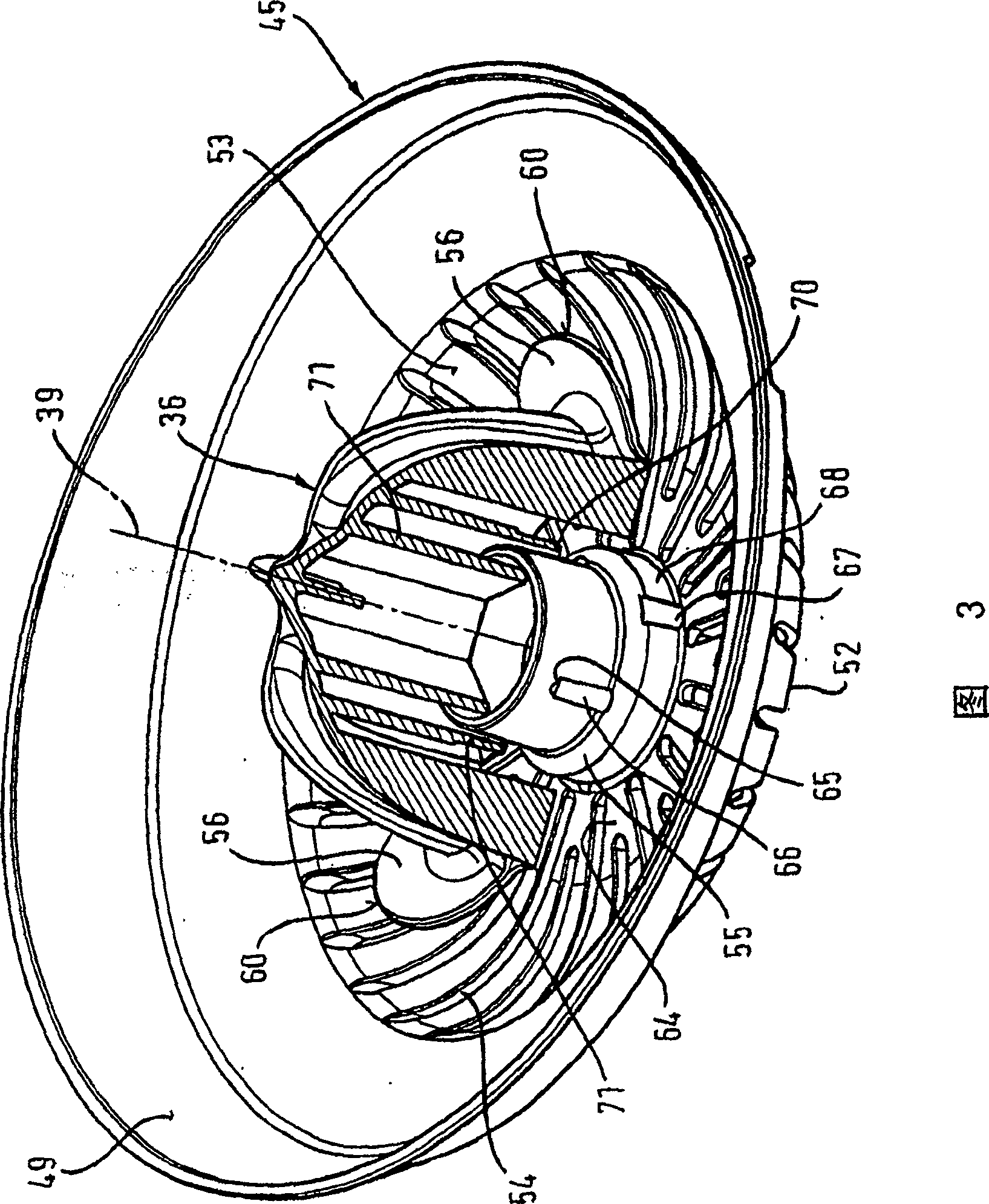

Juicer featuring gap adjustment

The invention relates to a juicer used especially for squeezing citrus fruit. Said juicer comprises a pressing cone (36) that is rotatable about the cone axis (39) thereof and a strainer area (45) which is disposed above a receptacle (37) for squeezed juice, is assigned to the pressing cone (36), and is provided with a juice-permeable zone having a modifiable cross section of passage. In order to control the pomace content in the squeezed juice, the strainer member encompasses a first strainer area (78) that is provided with first passageways (79) and is arranged such that the position thereof relative to a second strainer area (45) which is provided with second passageways (54) can be modified while the cross section of passage of the strainer member can be modified by changing the position of the first (78) and second strainer area (45) relative to each other. A greater or smaller quantity of pulp can reach the squeezed juice by displacing the first strainer area (78) relative to the second strainer area (45).

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

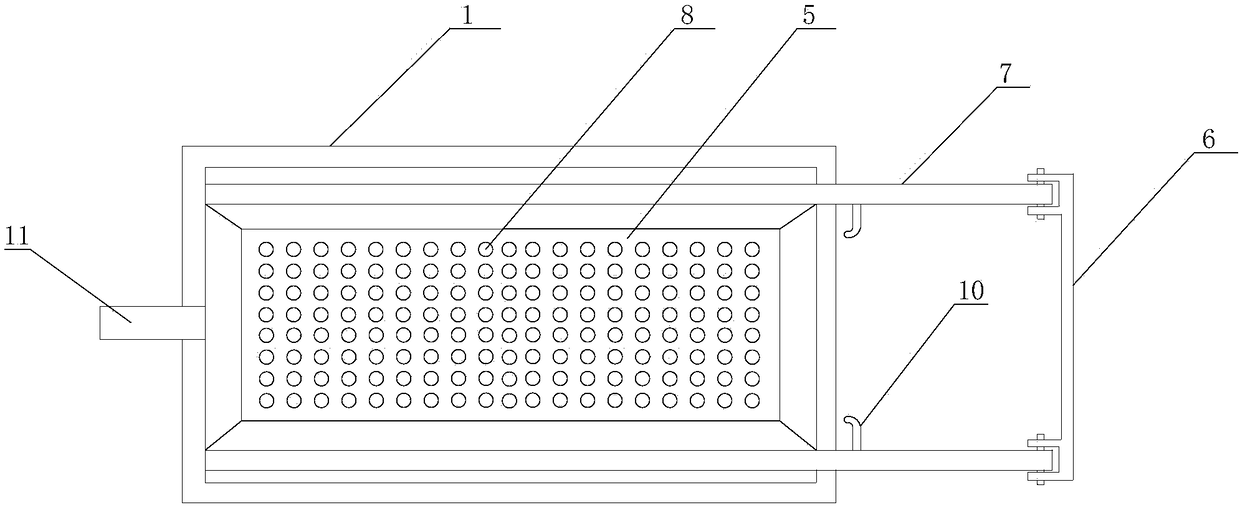

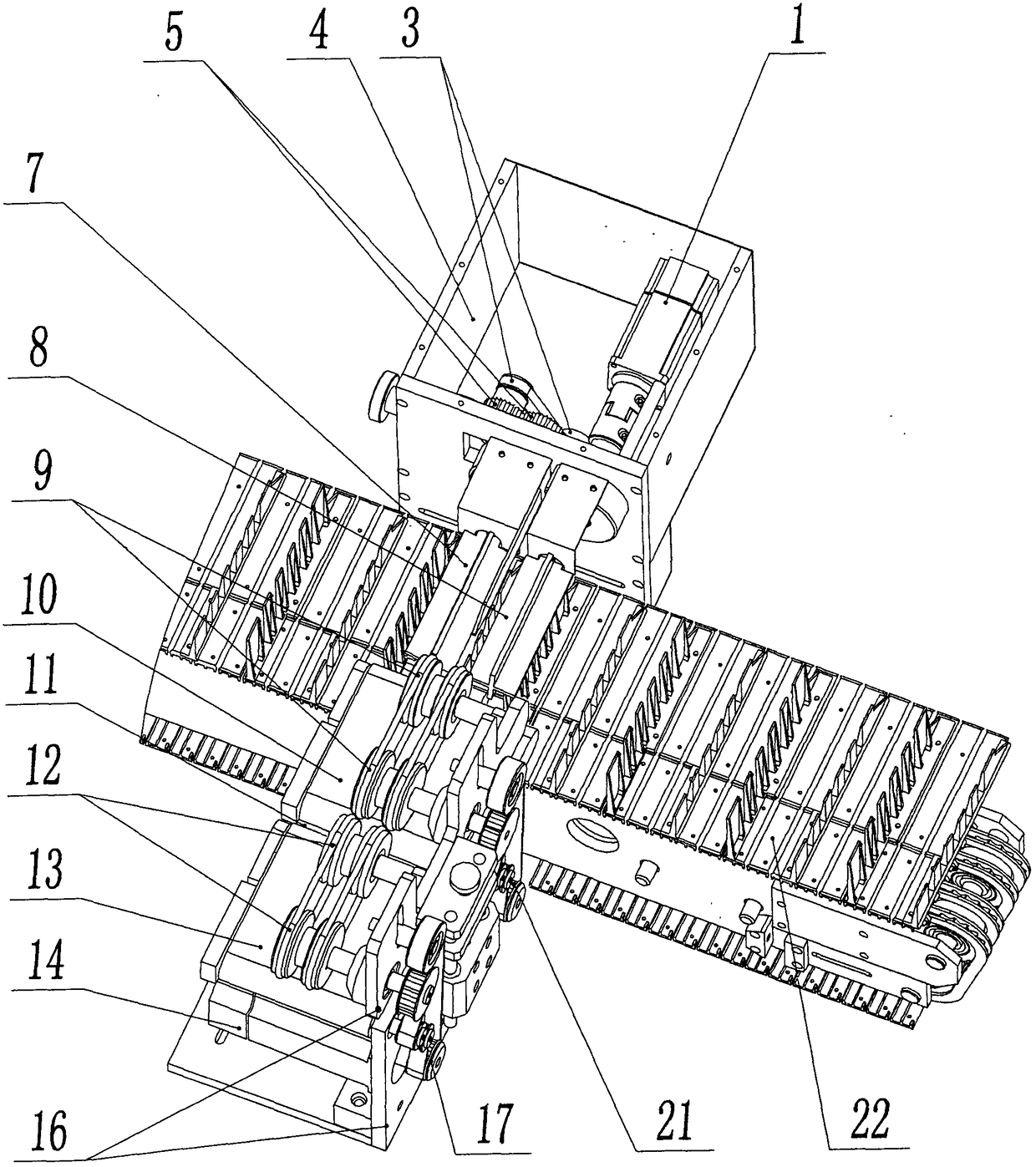

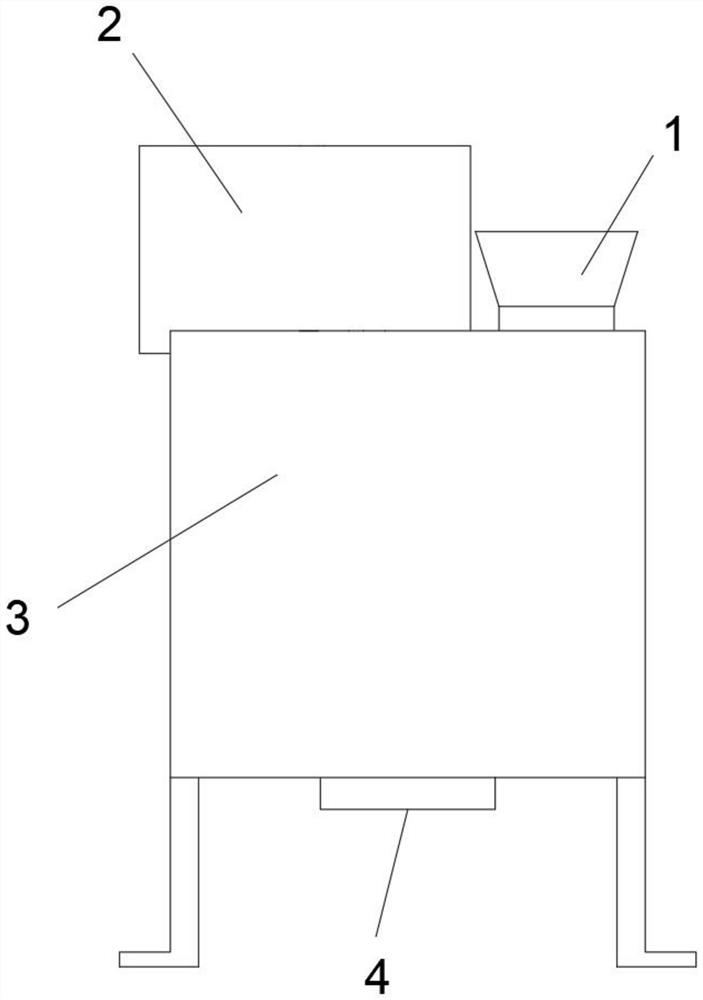

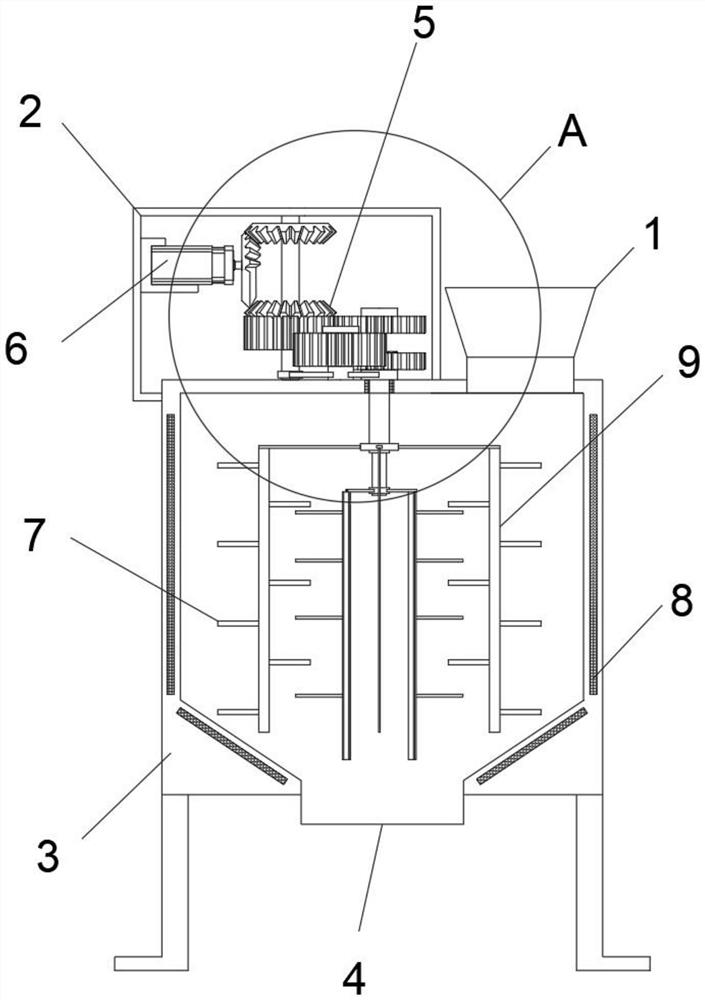

Raw material screening device for roller production

PendingCN111957436AAvoid manual deliveryConvenience fillerMagnetic separationLoading/unloadingGear driveElectric machine

The invention discloses a raw material screening device for roller production. According to the device, cast iron raw materials are placed in a storage hopper; a motor I is started to drive a conveyorbelt and a baffle to rotate; the baffle brings the raw materials in the storage hopper to a high position; a motor II is started to drive a gear I to rotate; the gear I is meshed with a half gear todrive the half gear to rotate; the half gear drives a transmission shaft to rotate; the transmission shaft drives a discharging groove to rotate, so that the discharging groove reaches the upper portion of an outer cylinder; by driving the discharging groove to rotate, in the working process of the outer cylinder, the discharging groove and the outer cylinder cannot make contact with each other, so that equipment can run more smoothly and cannot be damaged while the outer cylinder can be filled with materials conveniently; the motor is started to drive a rotating disc to rotate so as to drivethe outer cylinder to rotate, and each outer cylinder is filled with the materials; and after the filling is completed, the discharging groove is withdrawn. According to the invention, manual conveying of raw materials is avoided, only one outer cylinder is used for impurity removal, and the working efficiency is low.

Owner:马鞍山欧凯新材料科技有限公司

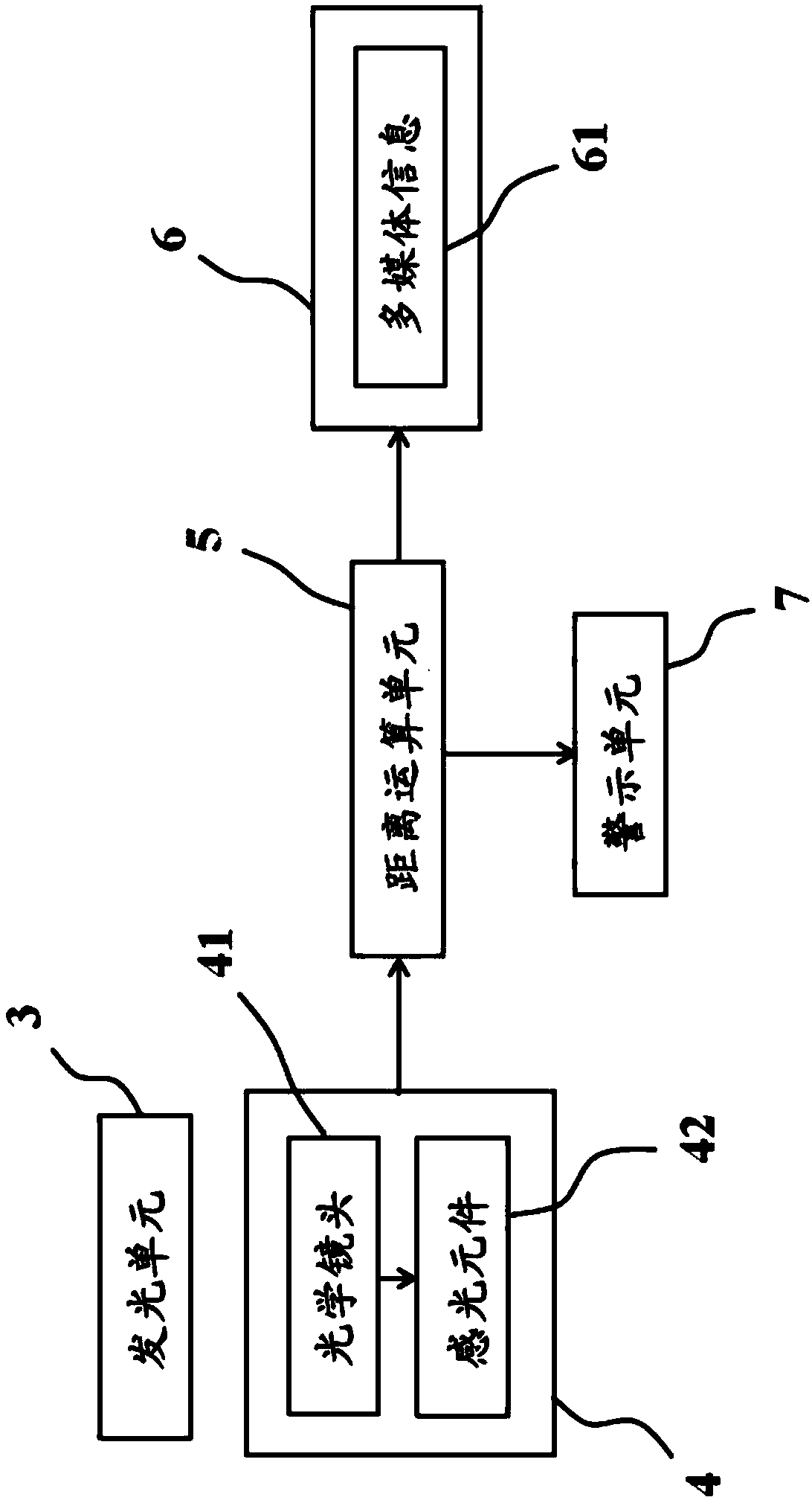

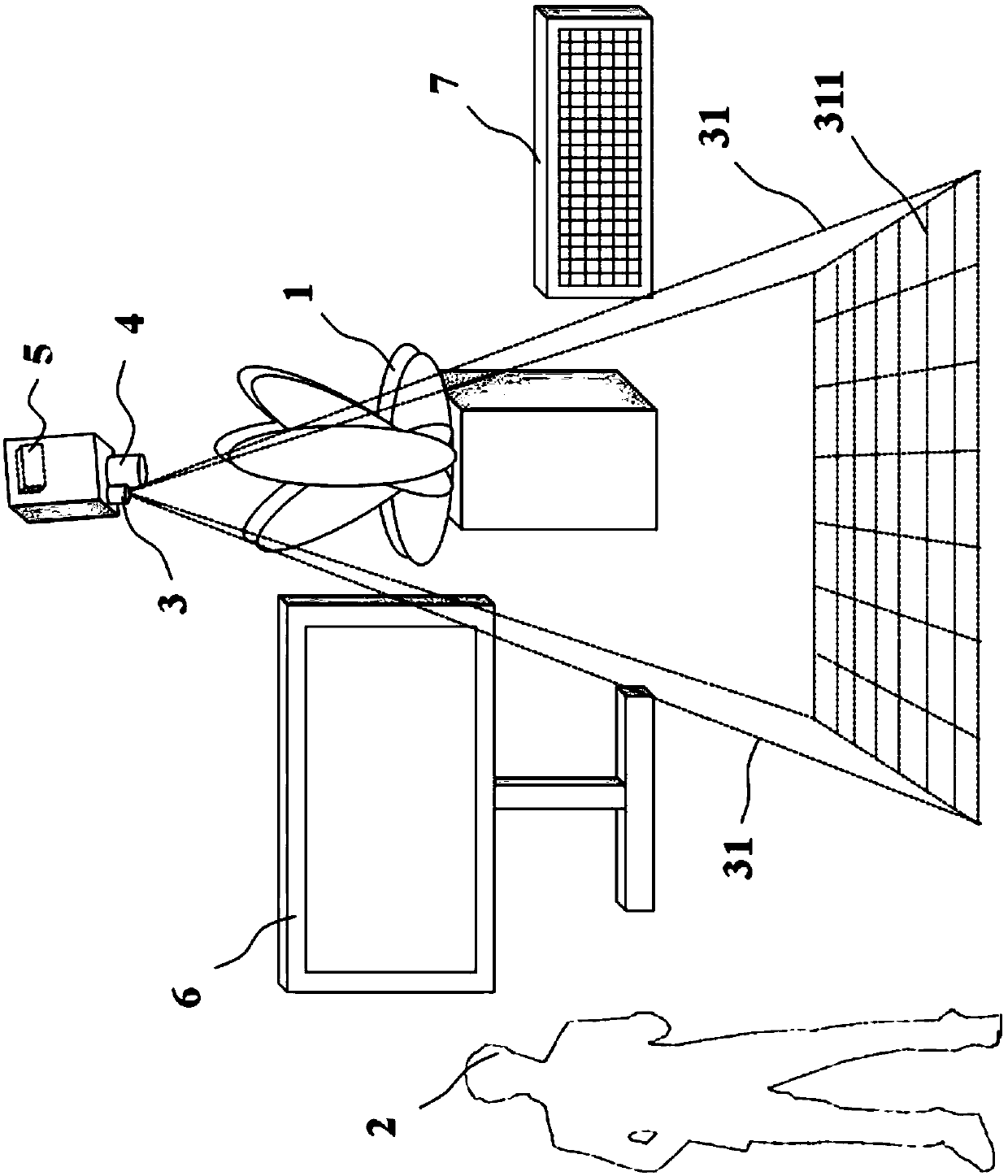

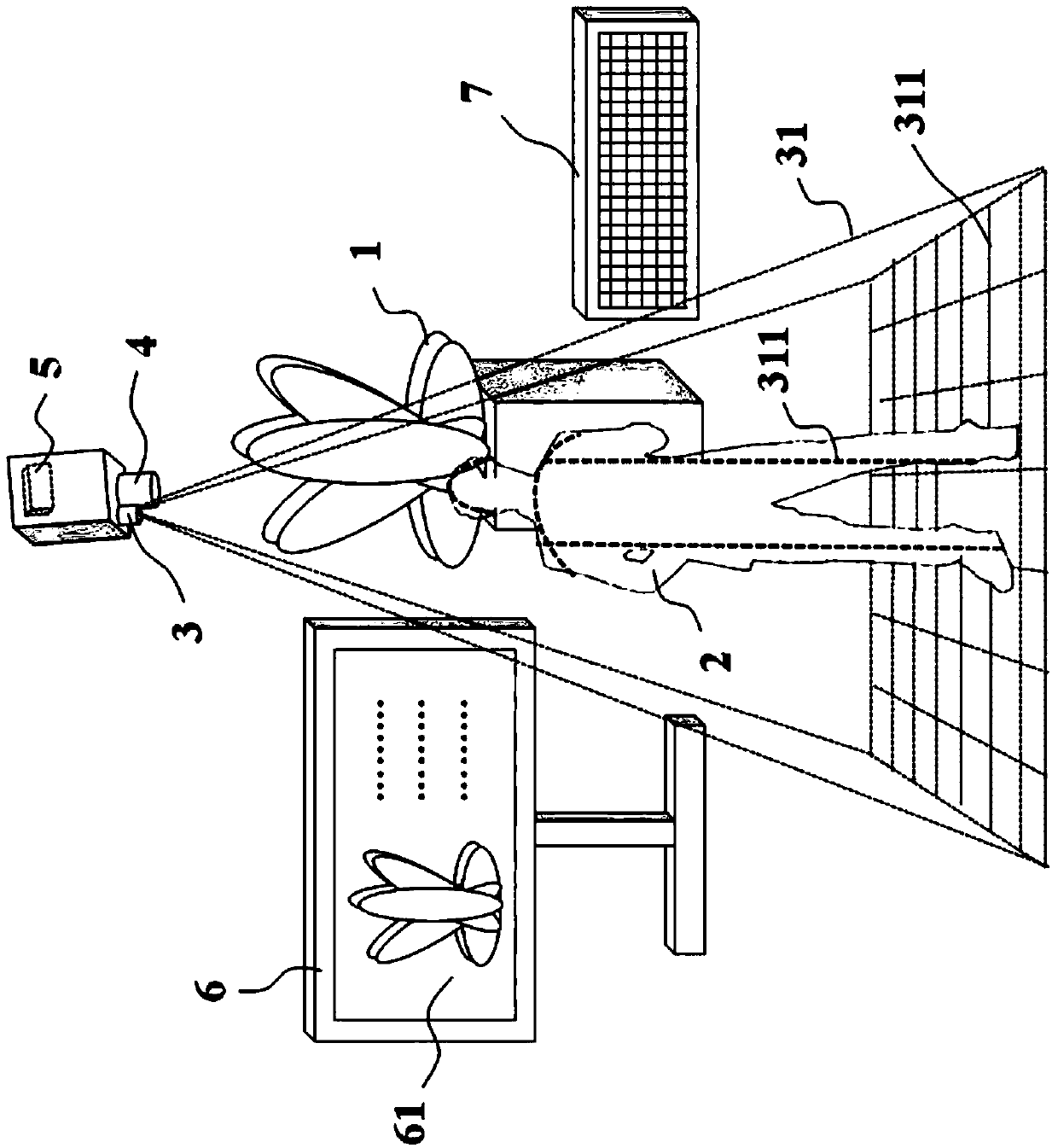

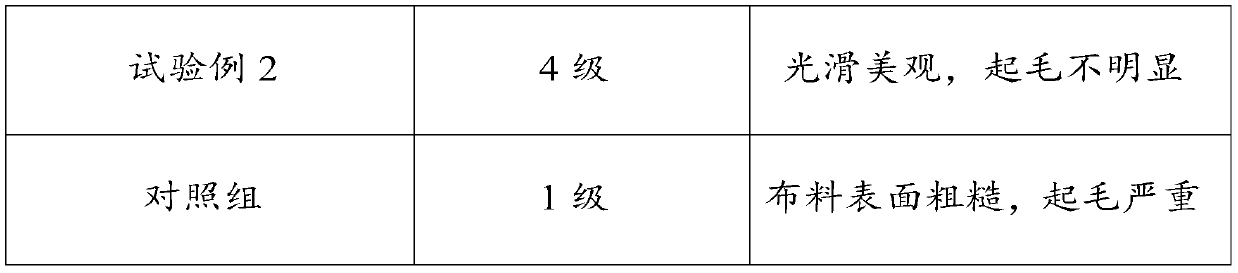

Interactive security alert system

InactiveCN107633630AAchieve zero-distance interaction functionSave human effortTelevision system detailsImage enhancementComputer visionLight-emitting diode

Owner:H P B OPTOELECTRONICS CO LTD

Wood cutting machine

PendingCN111571726AEasy to processNot easy to damageFeeding devicesGripping devicesStructural engineeringWood cutting

The invention provides a wood cutting machine, and belongs to the technical field of wood processing. The problem that a saw blade in an existing wood cutting machine is easy to damage is solved. Thewood cutting machine comprises a cutting mechanism, wherein the cutting mechanism comprises a first machine frame, a cutting table plate and a cutting machine head with a saw blade, a saw blade cutting hole is formed in the cutting table plate, the cutting mechanism further comprises a rotating base capable of rotating in the circumferential direction and a mounting frame fixed on the rotating base, the cutting table plate is fixed on the mounting frame, and a first driving piece for driving the cutting machine head to ascend and descend relative to the cutting table plate and capable of extending the part of the saw blade to the saw blade cutting hole is arranged on the mounting frame. In the process of cutting wood, the saw blade and the saw blade cutting hole are always in the aligned state, the problem that the saw blade and the saw blade cutting hole are difficult to align in the prior art is solved, it is ensured that the saw blade and the cutting table plate cannot touch, the saw blade is not easy to damage, and the service life of the saw blade is prolonged.

Owner:TAIZHOU EVOK MASCH CO LTD

Screening cat litter basin

The invention discloses a screening cat litter basin, and belongs to the field of cat litter basins. A filtering deice, a litter stopping plate and a litter discharging basin are arranged in the screening cat litter basin, and blocky objects formed by cat litter and excrement can be screened out. Operation is easy, convenient and fast, the cat litter does not need to be touched with one hand, thecleaner and more sanitary effect is achieved, the repeating utilization rate of the cat litter can be increased, and using requirements of persons are met.

Owner:自贡汉丰科技有限公司

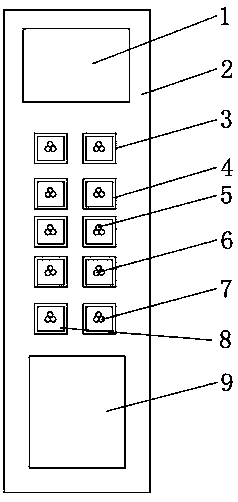

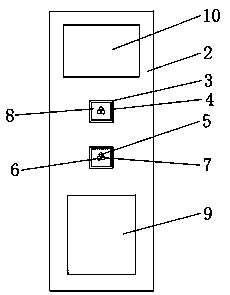

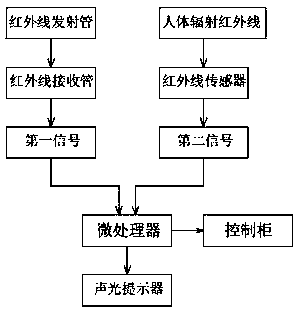

Non-contact induction elevator button and control method

The invention provides a non-contact induction elevator button and a control method. The non-contact induction elevator button comprises a button body, wherein the outer surface of the button body isprovided with a transmitting device, a receiving device and a prompting device, the transmitting device comprises an infrared transmitting tube, the receiving device comprises an infrared receiving tube and an infrared sensor, the prompting device comprises an acousto-optic prompter, the bottom of a button fixing plate is provided with an operation box, and a microprocessor and a power supply arearranged in the operation box. According to the button and the method, the infrared receiving tube receives infrared light beams shielded by the human body and sends a received first signal to the microprocessor, the infrared sensor receives infrared light radiated by the human body and sends a received second signal to the microprocessor, when the microprocessor detects the first signal and the second signal at the same time, the microprocessor sends the signals to a control cabinet, the control cabinet drives an elevator to operate, and double signal superposition control prevents elevator operation system disorder caused by accidental touch of other articles and prevents human body illness caused by cross infection due to direct contact between the human body and the button.

Owner:贾俊青

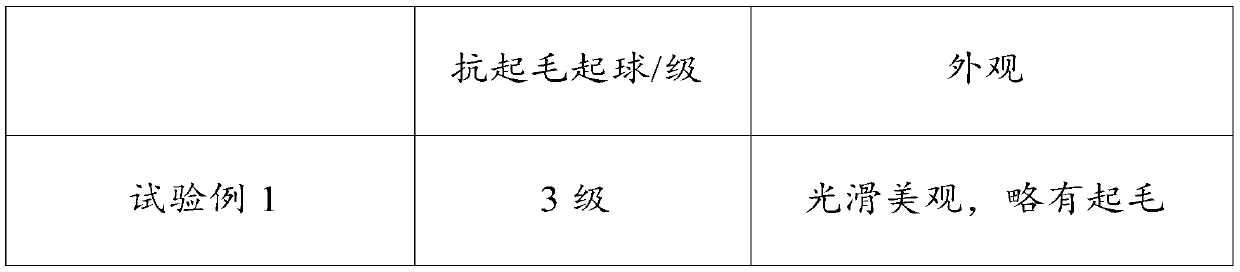

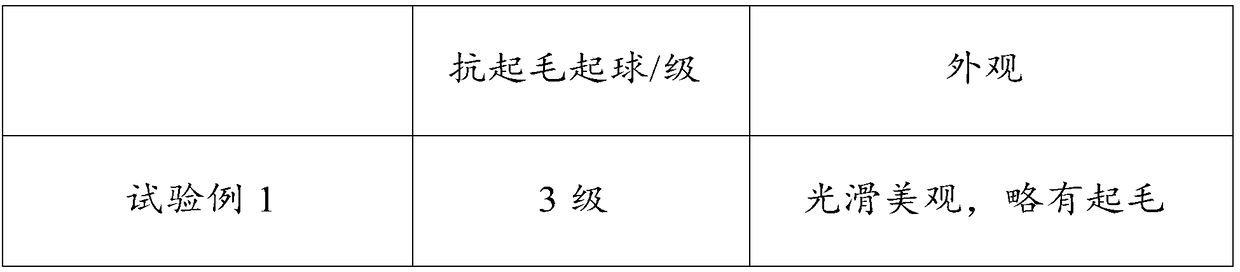

A kind of embroidery cloth and its manufacturing method

The invention relates to an embroidering fabric and a manufacturing method thereof, and belongs to the field of embroidery. The manufacturing method comprises the following steps that a fabric is dyedand subjected to first-time drying to obtain an initial fabric, the surfaces of embroidery threads are smeared with wax liquid, then the initial fabric is embroidered and smeared with a smoothing agent, and secondary drying is conducted on the initial fabric. The smoothing agent is prepared from, by weight, 8-10 parts of starch grafting sodium acrylate, 4-5 parts of organic silicon rubber, 2-3 parts of amino silicone microemulsion, 4-5 parts of lauric acid containing ester quaternary ammonium salt, 1.5-2 parts of imidazoline type surfactant, 1.5-2 parts of triethylene diamine and 50-60 partsof water through mixing. The preparation method is simple and convenient to conduct, the soft and smooth characteristics of the embroidering fabric can be maintained for a long time, the pilling or fluffing phenomenon can be avoided, and the embroidering fabric is especially suitable for the manufacturing of embroidery clothing of the Miao nationality and the Dong nationality. The embroidering fabric manufactured by the manufacturing method is soft and smooth, and after the embroidering fabric is in contact with the skin, no uncomfortable touch feeling is generated.

Owner:贵州凯里经济开发区鑫田民族服饰工艺品发展有限公司

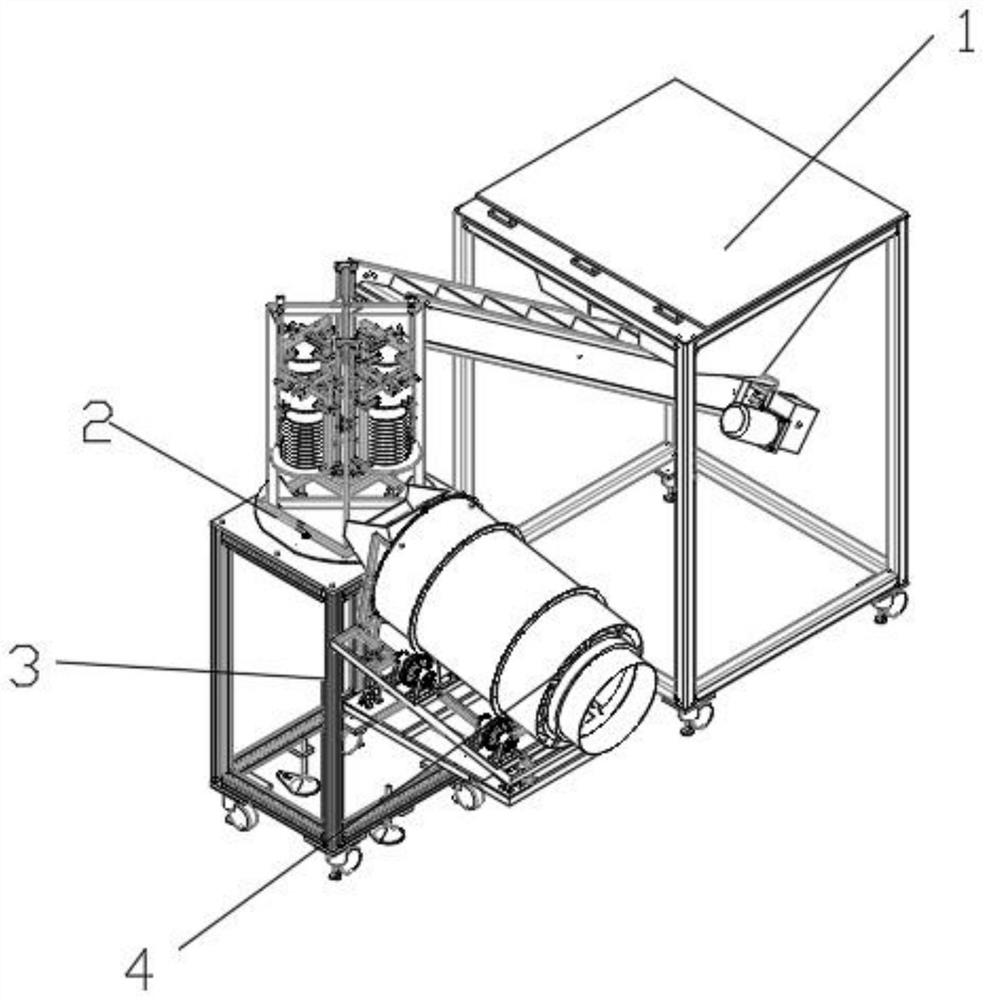

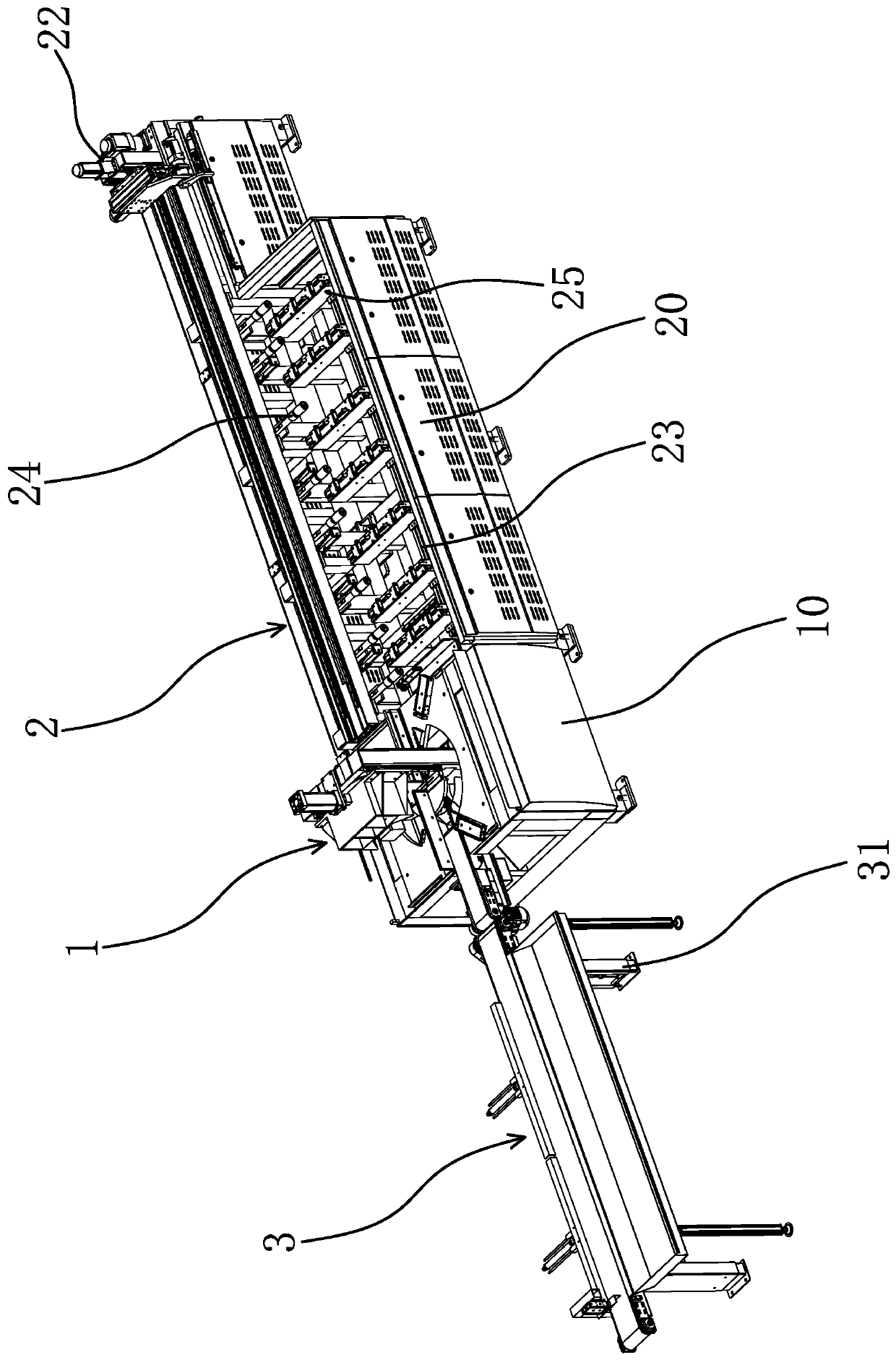

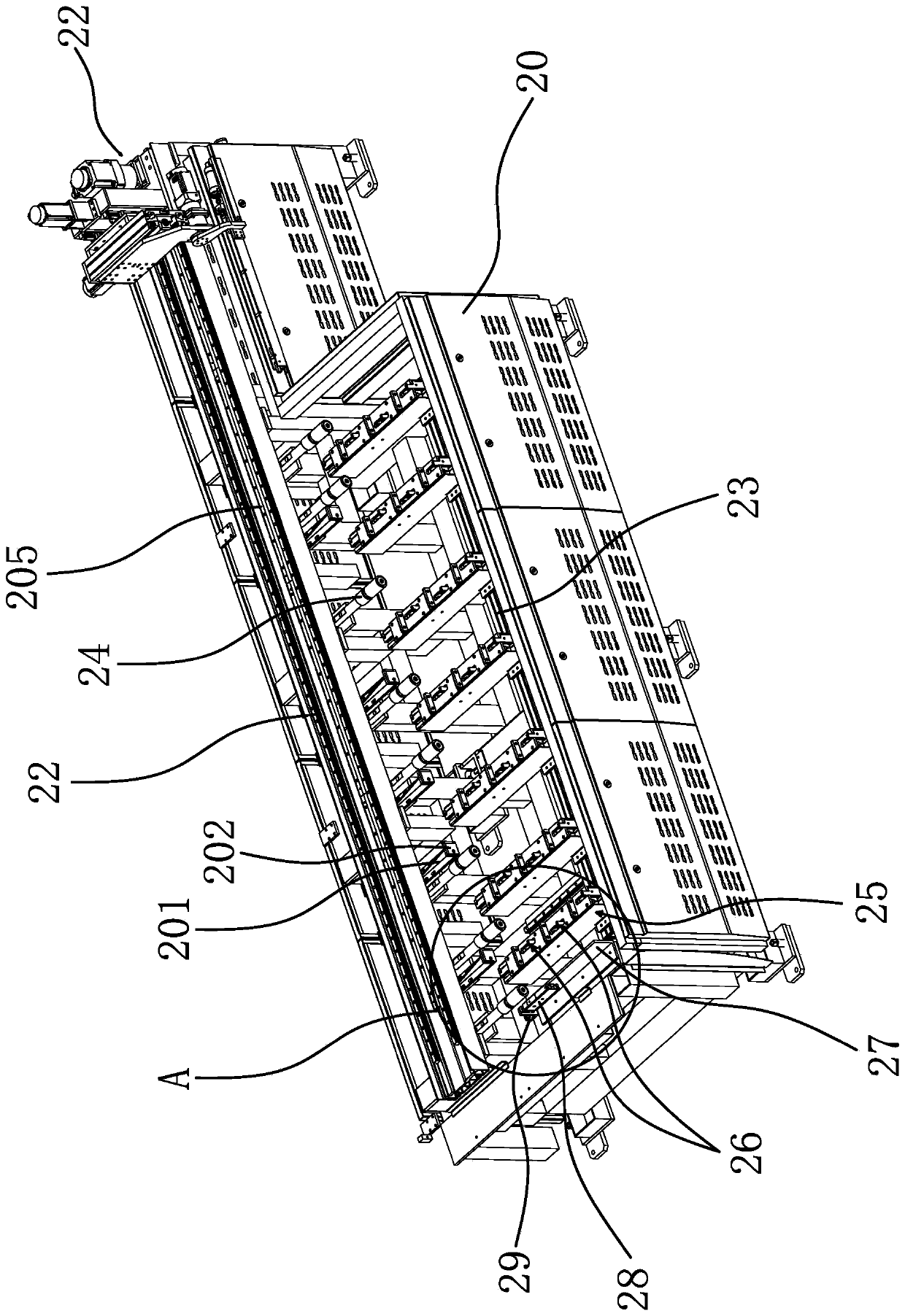

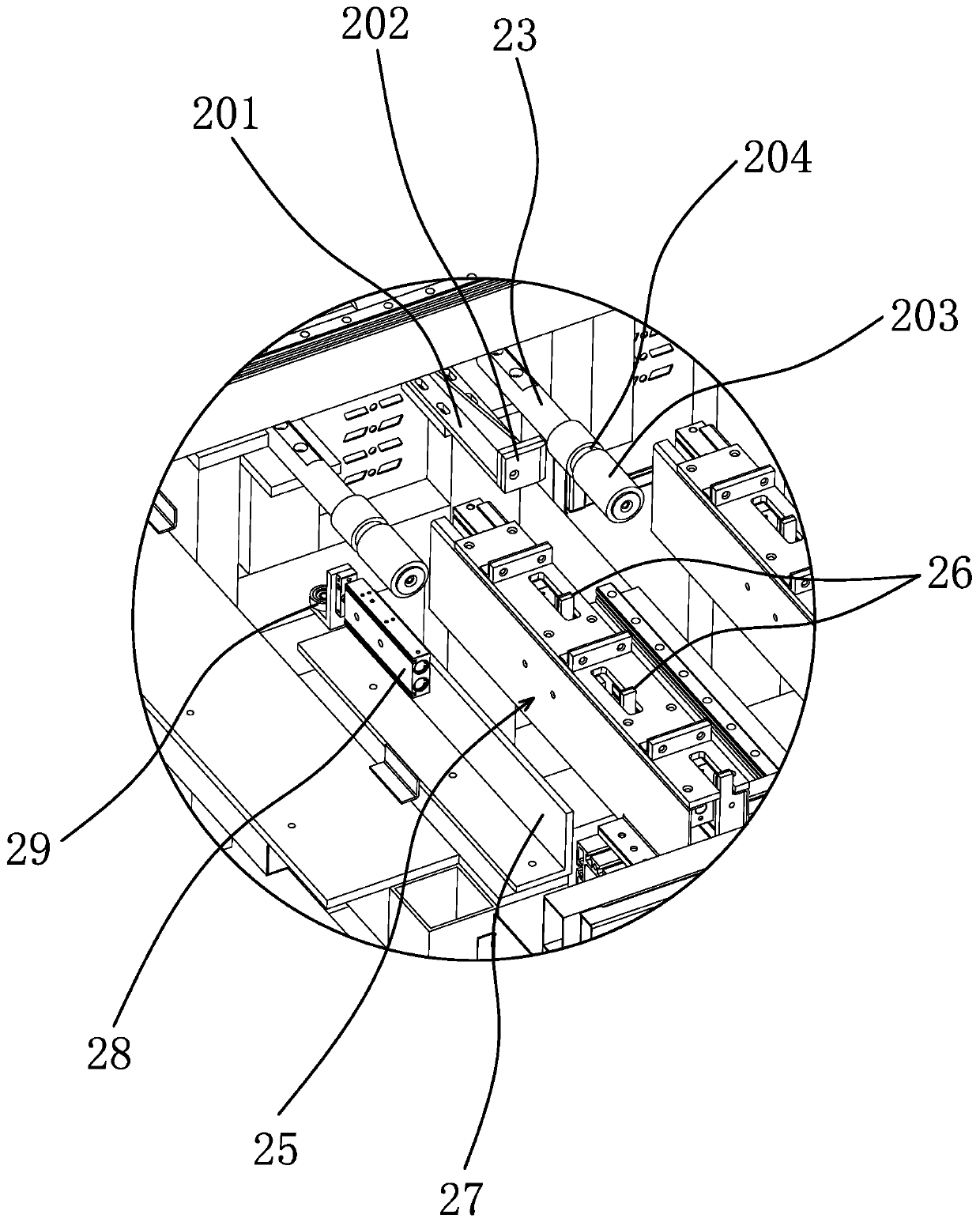

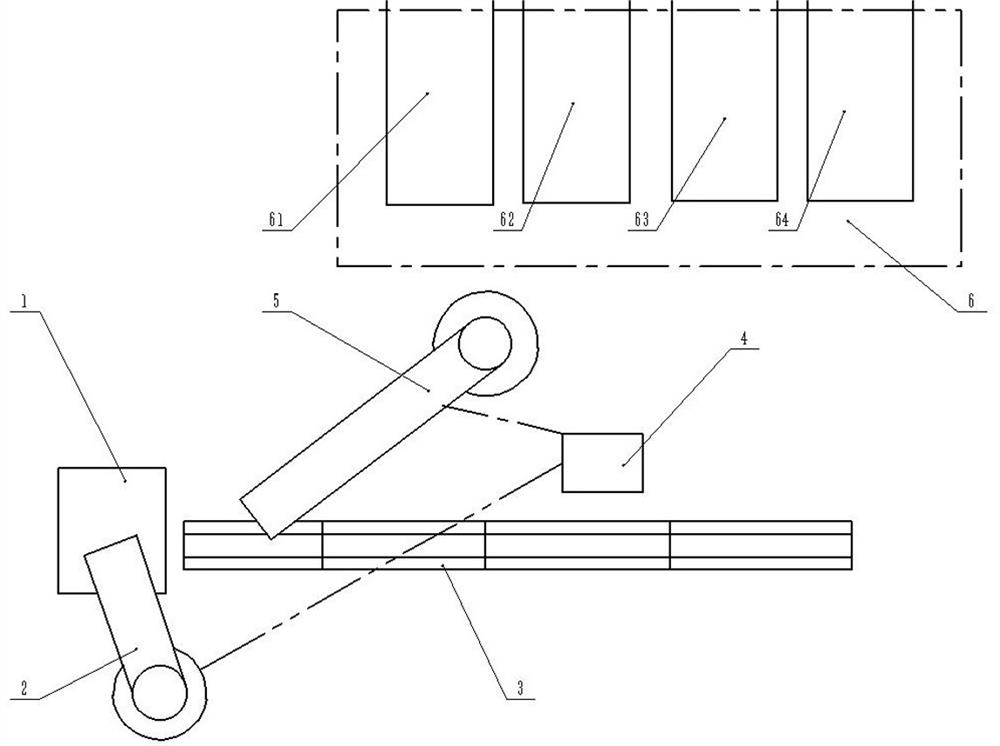

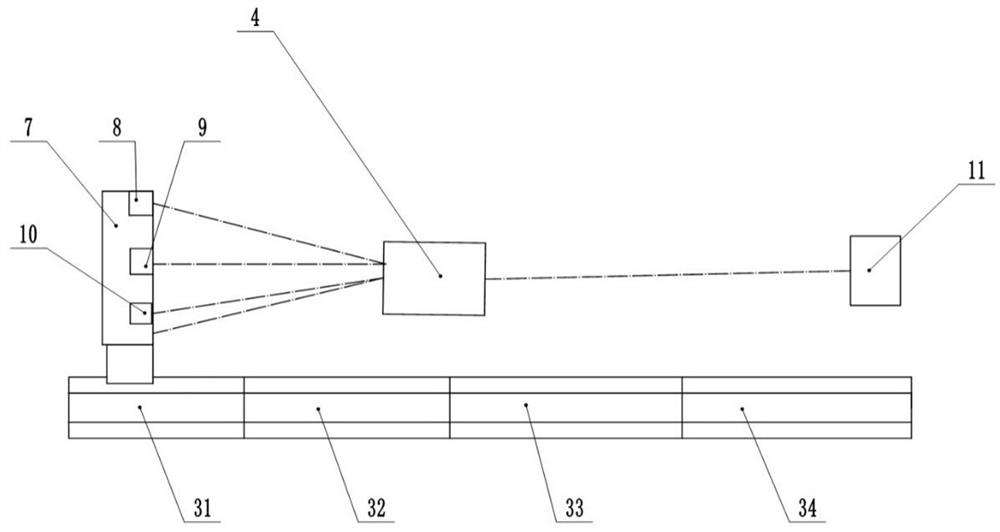

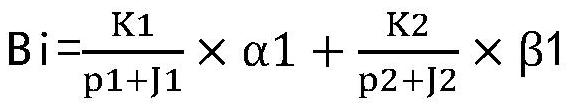

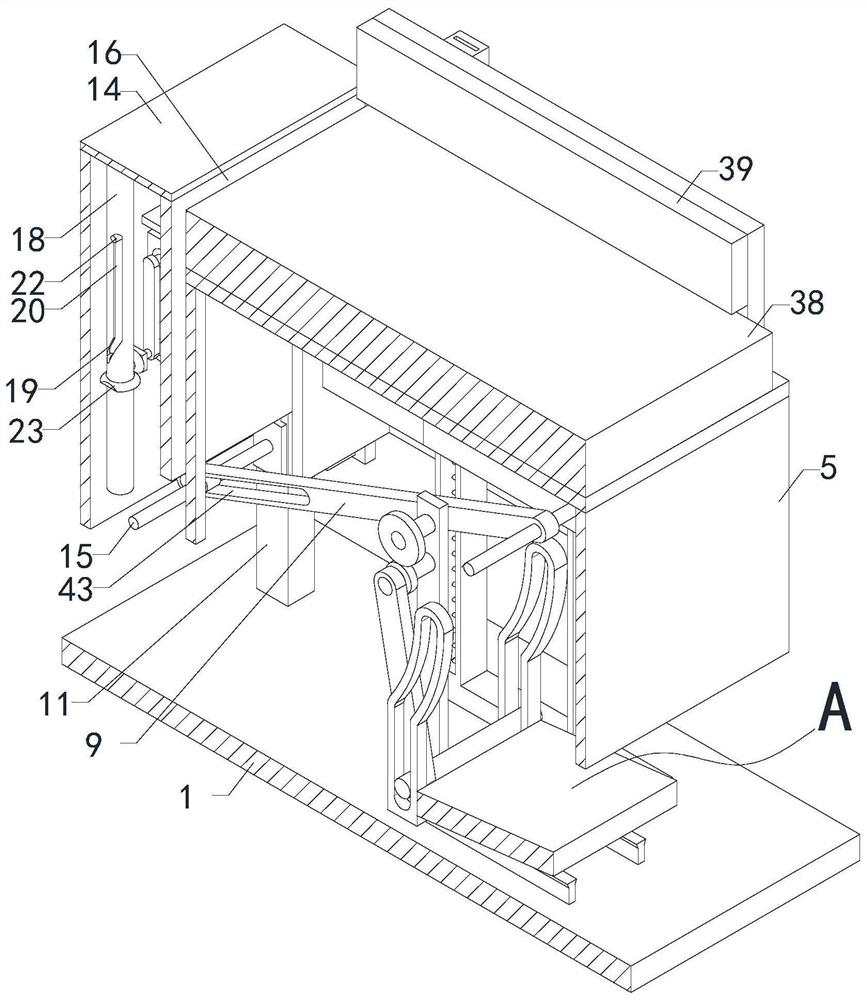

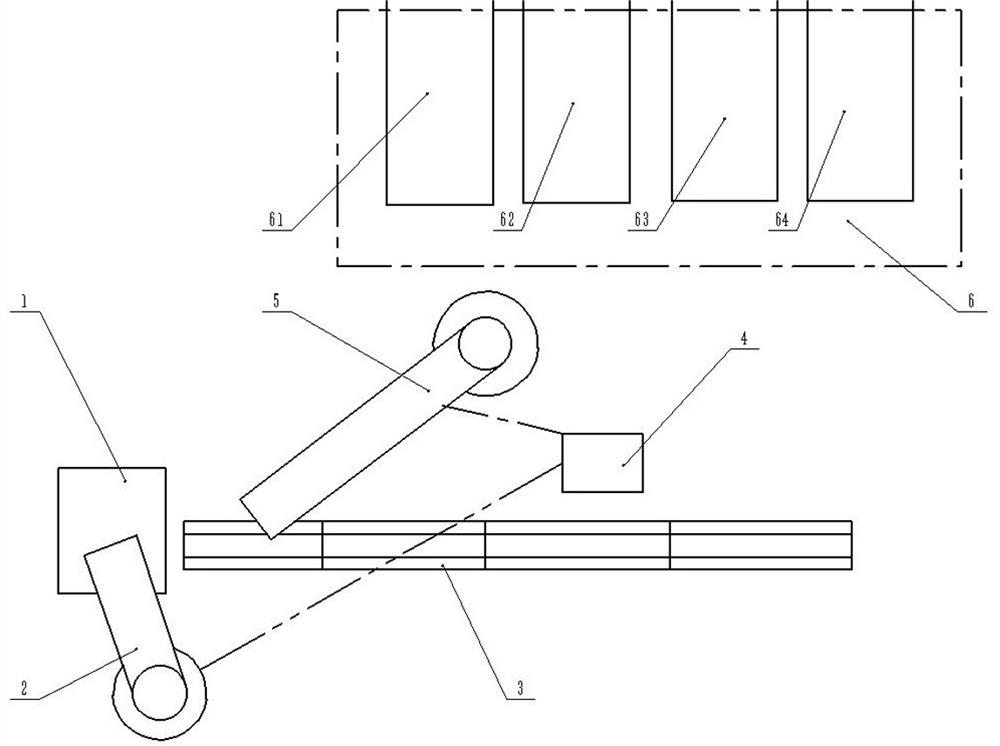

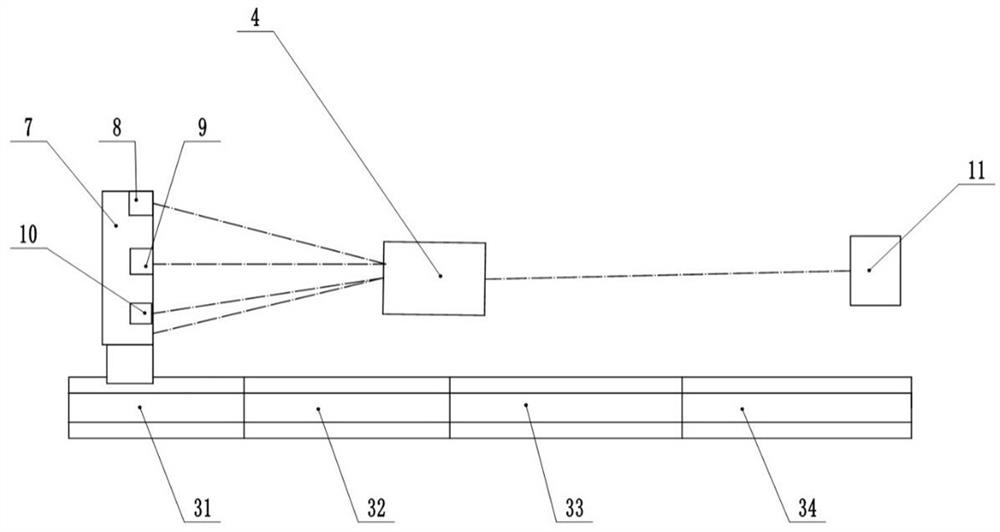

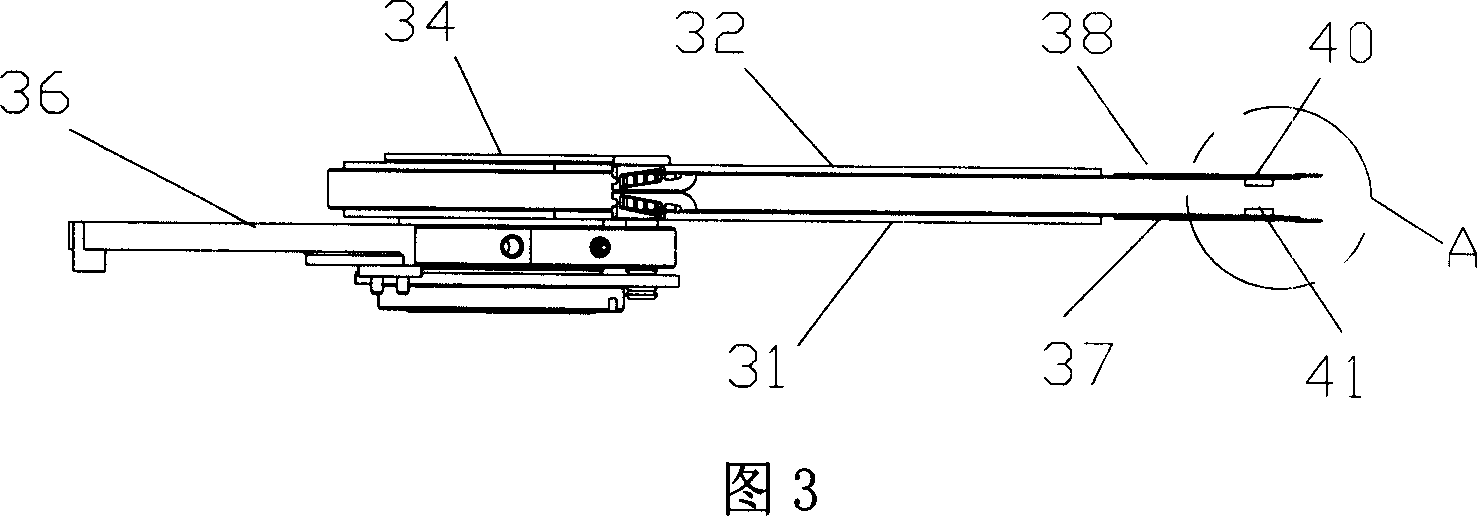

A self-transport detection platform based on slider detection

ActiveCN111929052BImprove detection efficiencyImprove the level of industrializationProgramme controlMachine part testingTrackwayClassical mechanics

The invention relates to a self-transport detection platform based on slider detection, which includes a storage box for sliders to be inspected, a first manipulator, a second manipulator, a plurality of slider running tracks, a pressure column, a central control module, a surface detector and Multiple slider conveyor belts. In the present invention, the slider to be detected is grasped and placed from the storage box of the slider to be inspected by the manipulator to the running track of the slider to be inspected, the pressure column presses the slider from top to bottom, and the integrity of the balls inside the slider is detected by the first section of the track. and smoothness, the second, third, and fourth sections of the track detect the jumping value and working capacity of the slider. A surface detector is installed at the end of the fourth section of the track to detect the surface state of the slider. The test results of each item have corresponding scores, and the sliders to be checked are classified according to the grades according to the final test scores.

Owner:温州深信云电子科技有限公司

Multifunctional seat for 4D cinema

The invention relates to the technical field of cinema accessory devices, in particular to a multifunctional seat for a 4D cinema, during use, when a user sits on the seat, a back support can be automatically lifted without hindering a viewer from watching a movie, and a foot support can automatically stretch out without hindering walking of people; comprising a bottom plate, two F-shaped plates are fixed to the bottom plate, first long-strip-shaped holes are formed in the vertical sections of the F-shaped plates, first sliding blocks are arranged at the first long-strip-shaped holes in a sliding mode, door-shaped fixing plates are fixed to the two first sliding blocks located on the same side, a seat body is fixedly installed on the two fixing plates jointly, and second long-strip-shaped holes are formed in the fixing plates; a supporting plate is fixed to the bottom plate, a supporting shaft is rotationally installed on the supporting plate, a driving rod is fixed to the supporting shaft, a first driving shaft is fixed to one end of the driving rod, and the two ends of the first driving shaft extend into the two second long-strip-shaped holes correspondingly.

Owner:宁波胜利映画文化传媒股份有限公司

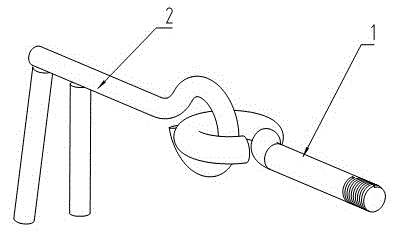

Coating and positioning device for car door

InactiveCN103551287ANo touchImprove coating qualityLiquid surface applicatorsSpraying apparatusCar doorCoating

The invention relates to a coating and positioning device for a car door. The coating and positioning device is characterized by being provided with a side wall connection rod and a car door fixing bracket, wherein a thread is arranged at one end of the side wall connection rod; the other end of the side wall connection rod is in a hooked annular shape; a U-shaped fixed socket is arranged at the other end of the car door fixing bracket; the other end of the car door fixing bracket is in the hooked annular shape; the hooked annular shape of the side wall connection rod is connected with the hooked annular shape of the car door fixing bracket. The coating and positioning device for the car door is reasonable in design, simple in structure, low in cost, easy to manufacture, convenient to use and operate and reliable to position; the coating and positioning device does not collide in the coating process of the car door and the coating quality of cars can be improved.

Owner:ZHONGHANG HEIBAO

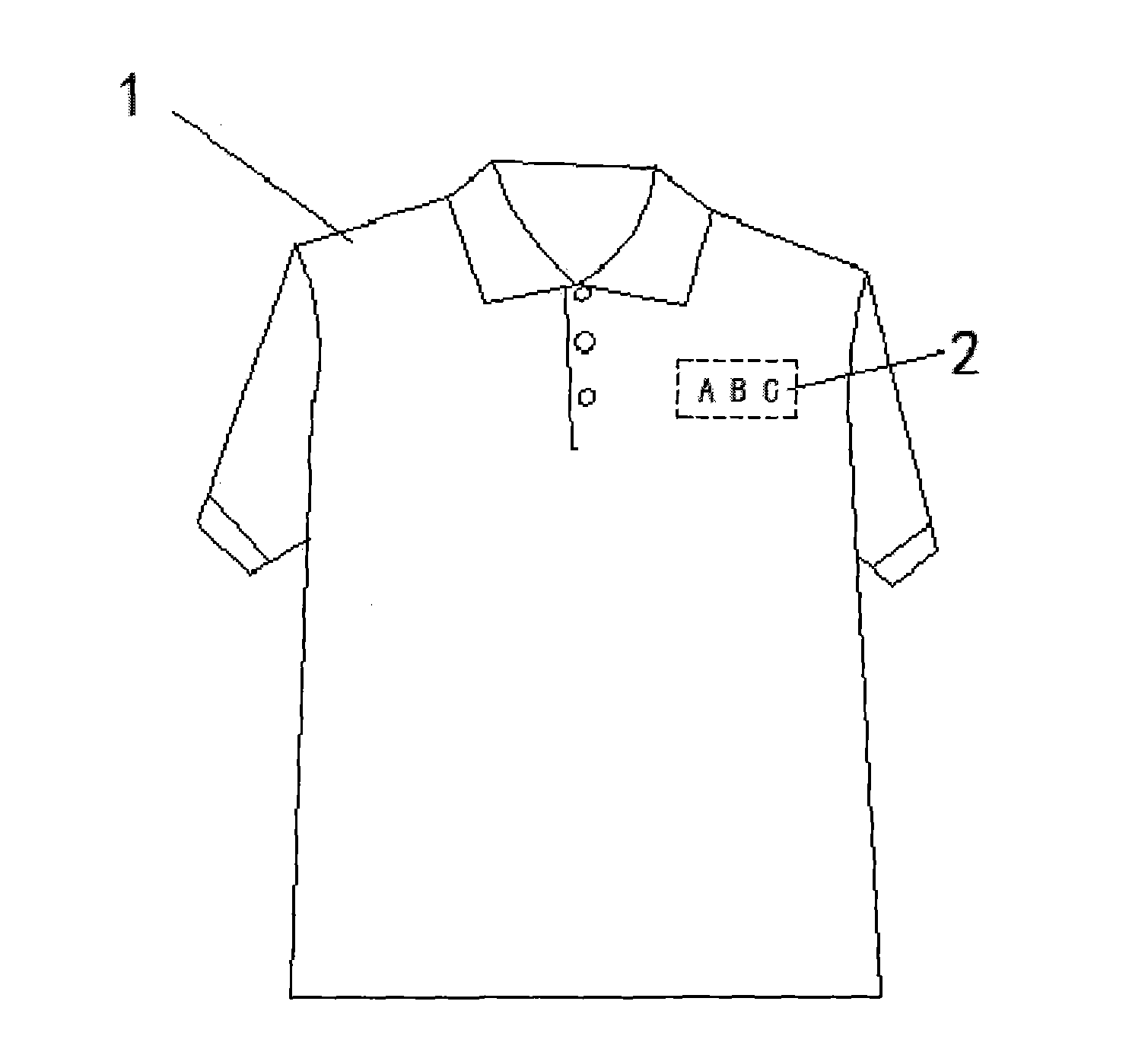

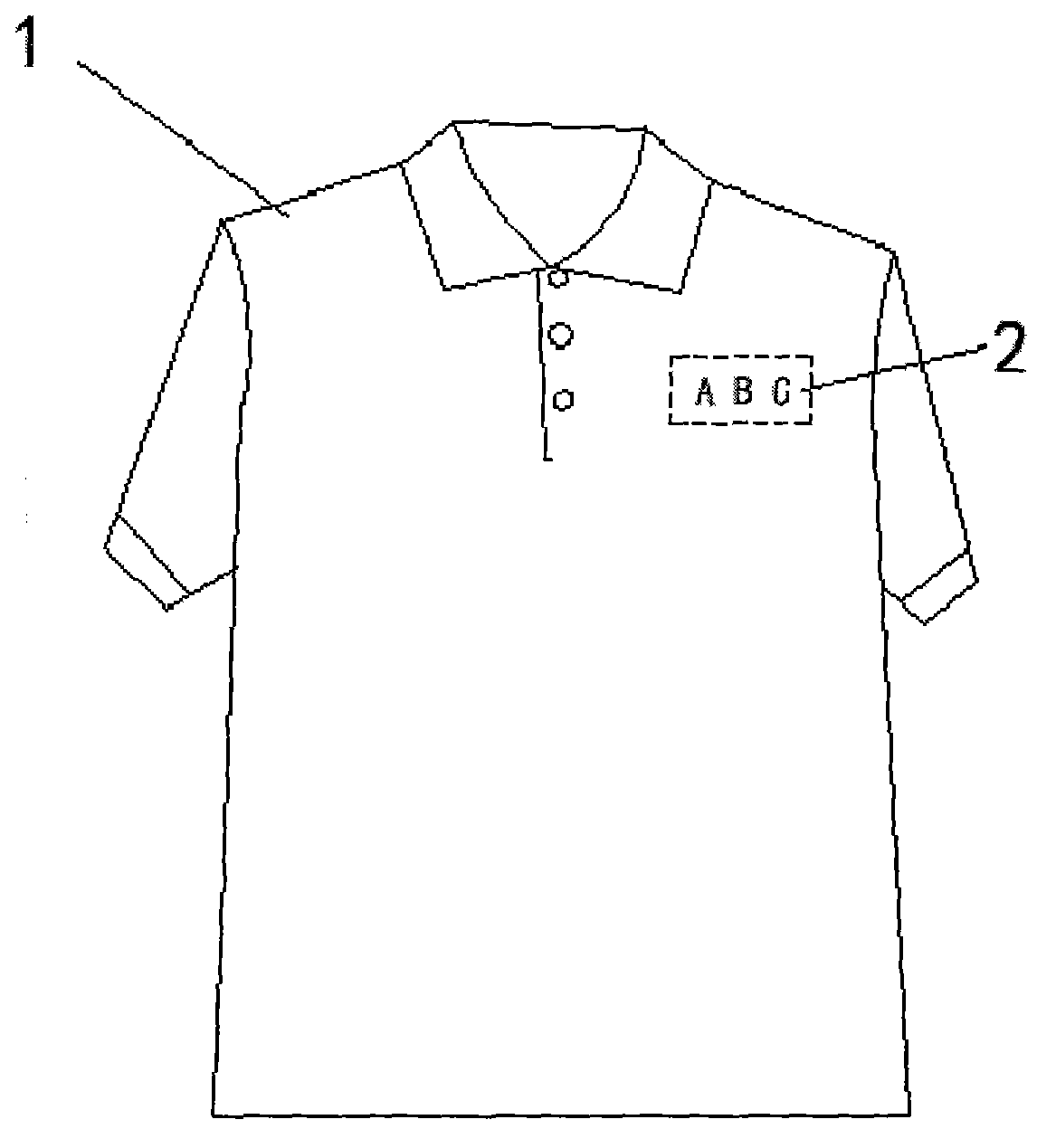

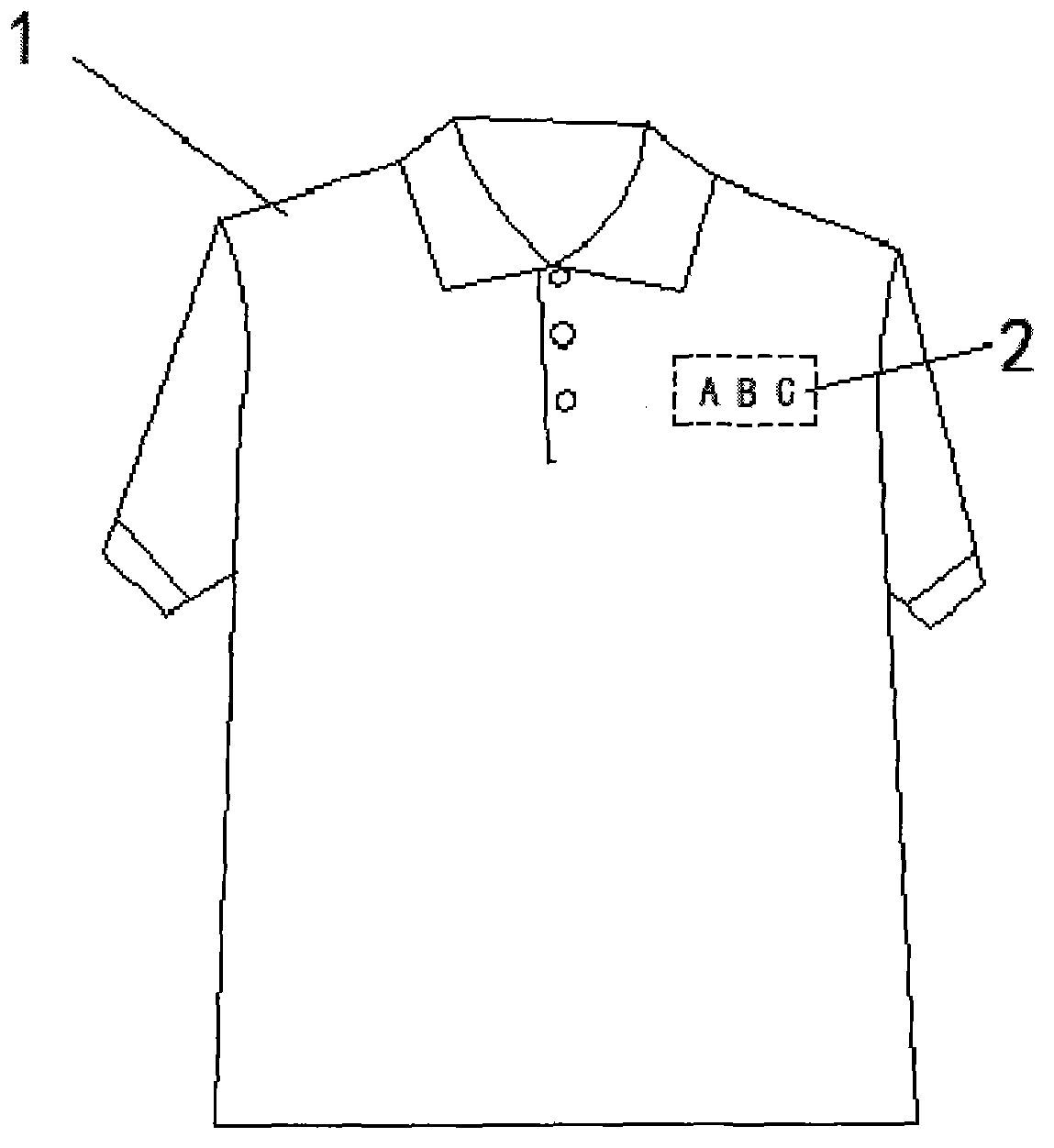

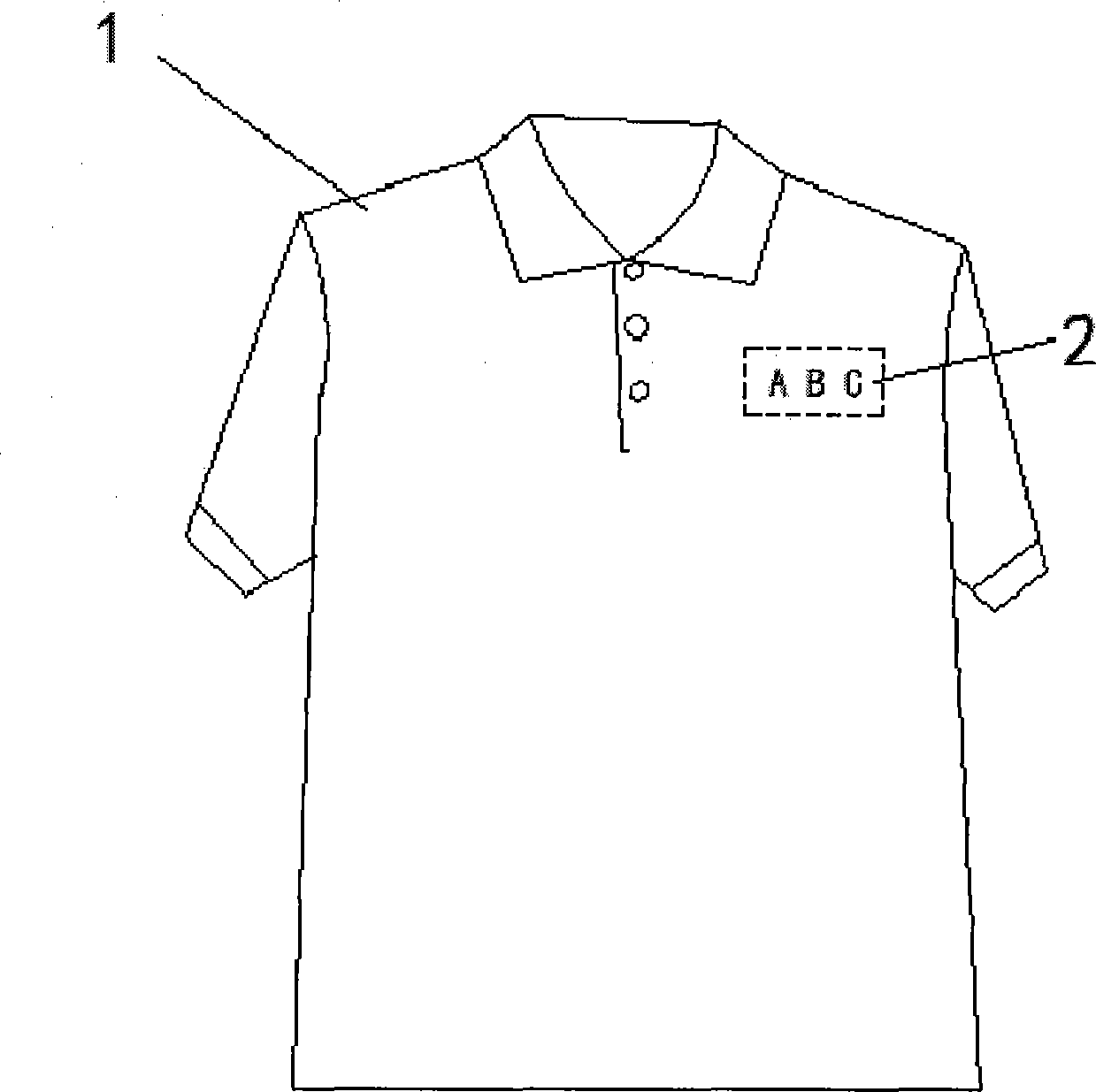

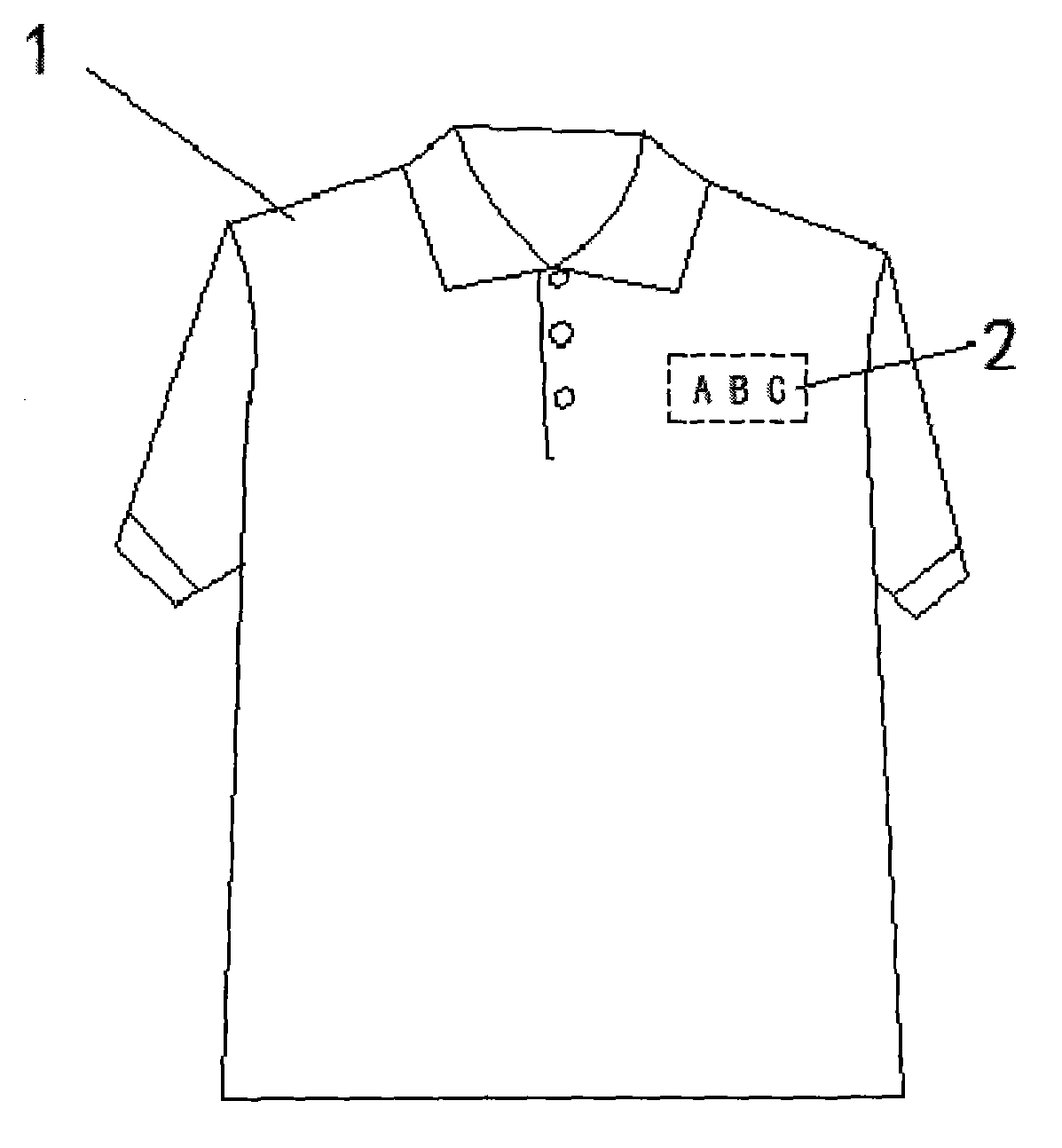

Shading fabric garment with trademark free of touch

InactiveCN103653445ANo touchImprove privacyProtective garmentSpecial outerwear garmentsHuman skinSurface layer

The invention relates to a garment, in particular to a shading garment with a trademark free of touch. The garment comprises a garment body (1) and is characterized in that a piece of smooth rectangular cloth (2) adheres to the inner side of the trademark of the garment body (1) and all wraps stitches on the inner side of the trademark, the garment body (1) is made of a fabric, and the fabric comprises a surface layer, a lining layer and a middle layer connected between the surface layer and the lining layer, and the surface layer and the lining layer form a whole by warp and weft interweaving. The stitches on the inner side of the trademark cannot be in direct contact with the skin of the human body, and accordingly the effect of being free of trademark touch is achieved. The garment has a shading function.

Owner:黄磊

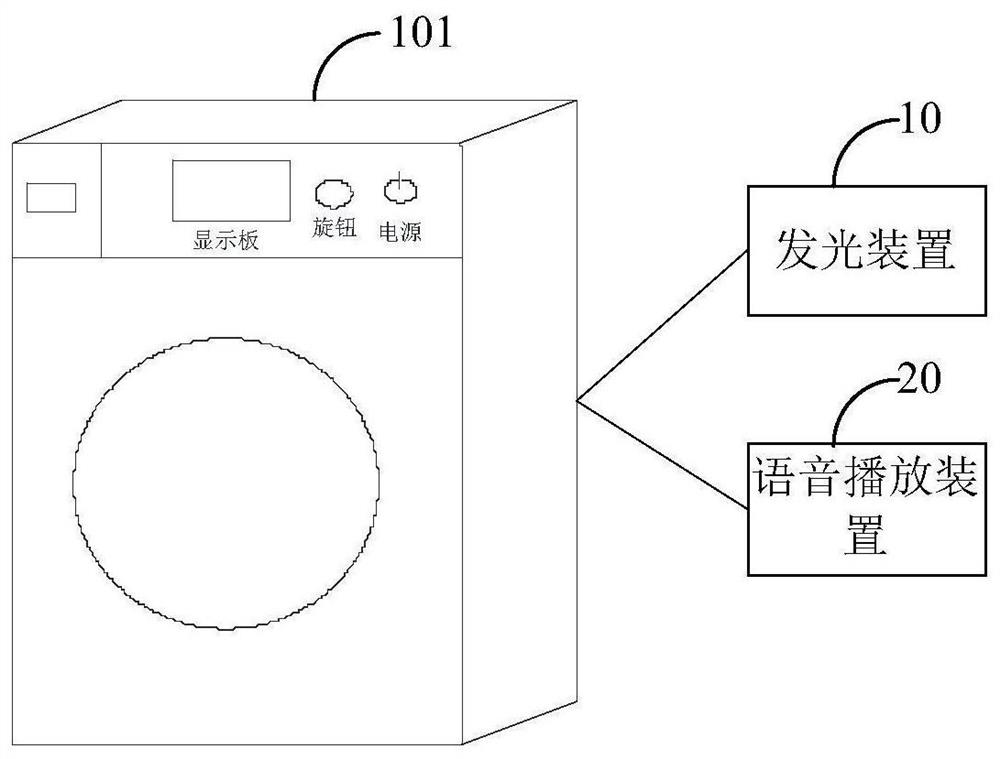

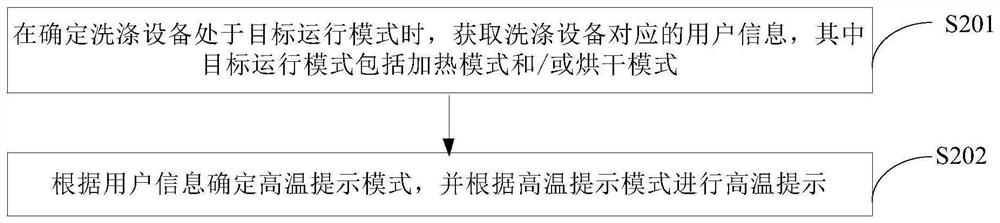

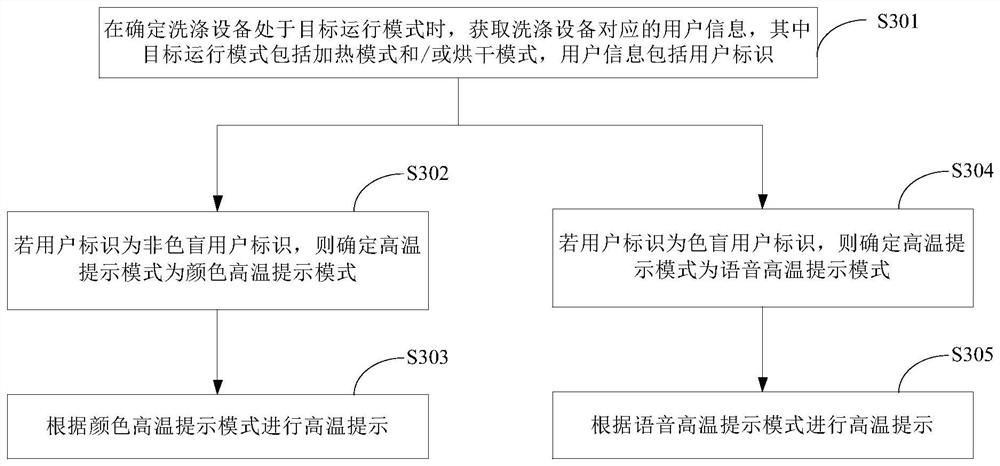

High-temperature prompting method and washing equipment

PendingCN114541091AImprove experienceAvoid burnsControl devices for washing apparatusTextiles and paperThermodynamicsLaundry washing machine

The invention provides a high temperature prompting method and washing equipment, which are applied to an intelligent washing machine, and the method comprises the following steps: when determining that the washing equipment is in a target operation mode, obtaining user information corresponding to the washing equipment; wherein the target operation mode comprises a heating mode and / or a drying mode; the high-temperature prompting mode is determined according to the user information, high-temperature prompting is carried out according to the high-temperature prompting mode, so that a user knows that the temperature of the washing equipment is too high, touch is forbidden to avoid scalding, prompting is carried out through the high-temperature prompting mode suitable for the user when high-temperature prompting is carried out, the prompting success rate is increased, and the user experience is improved. Therefore, the user can be effectively prevented from being scalded, the user use degree is improved, and the user experience is improved.

Owner:QINGDAO HAIER DRUM WASHING MACHINE +1

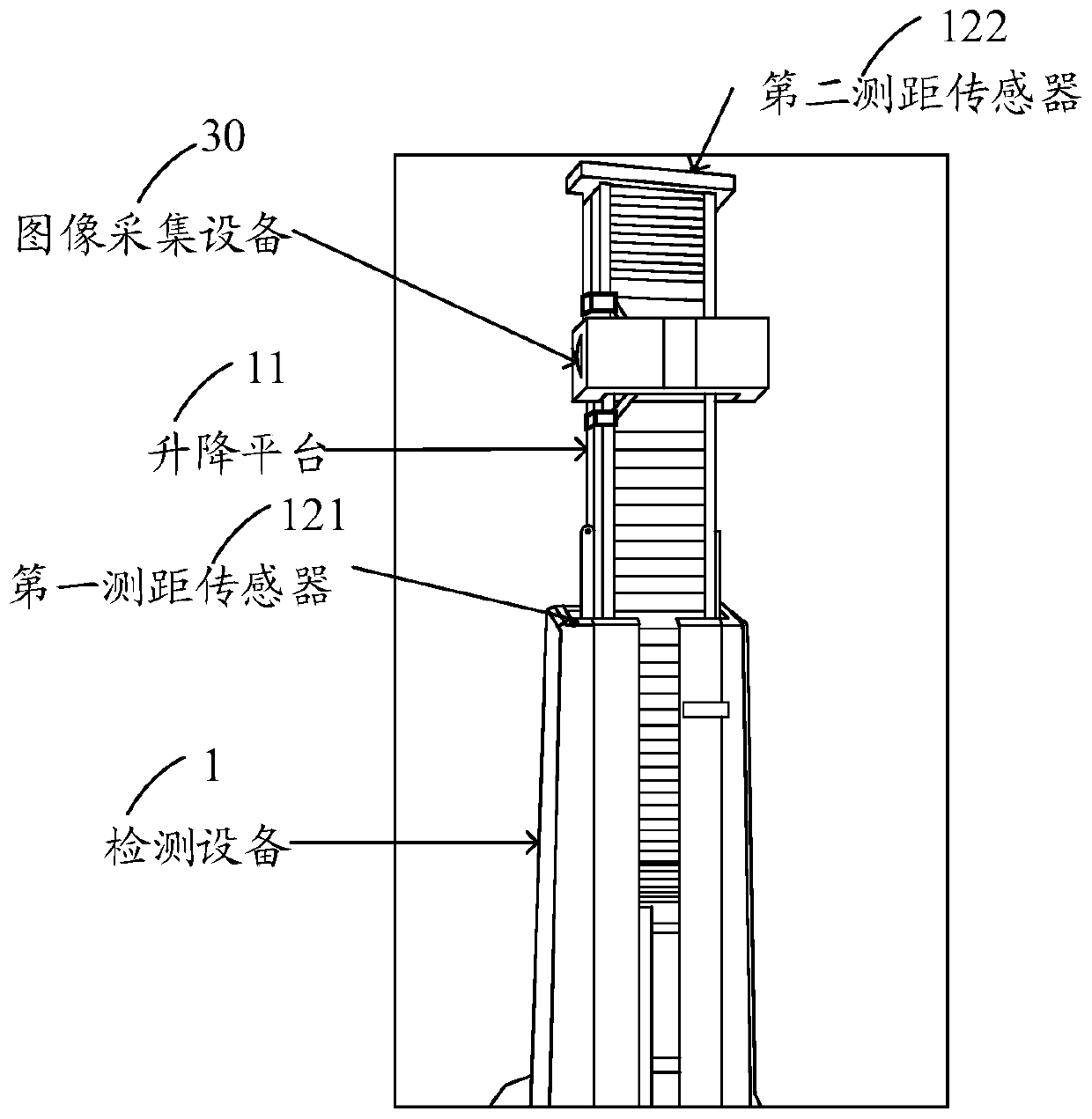

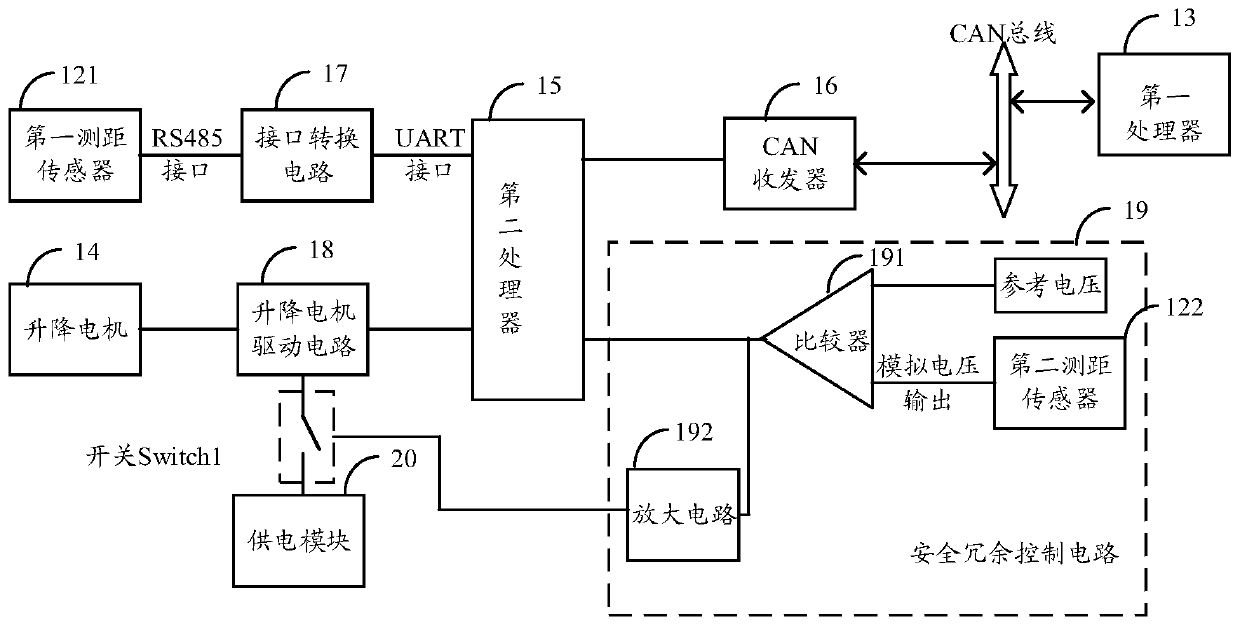

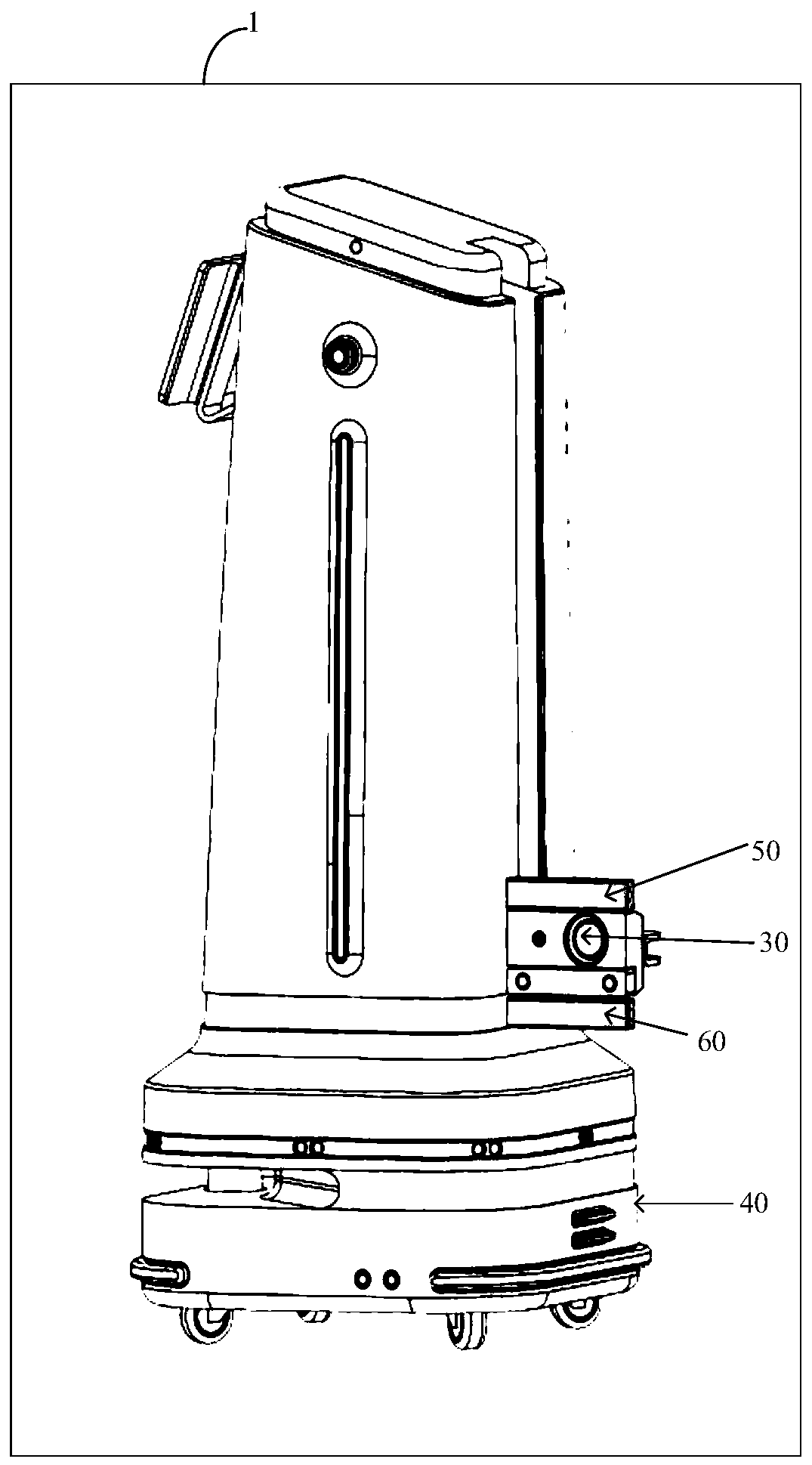

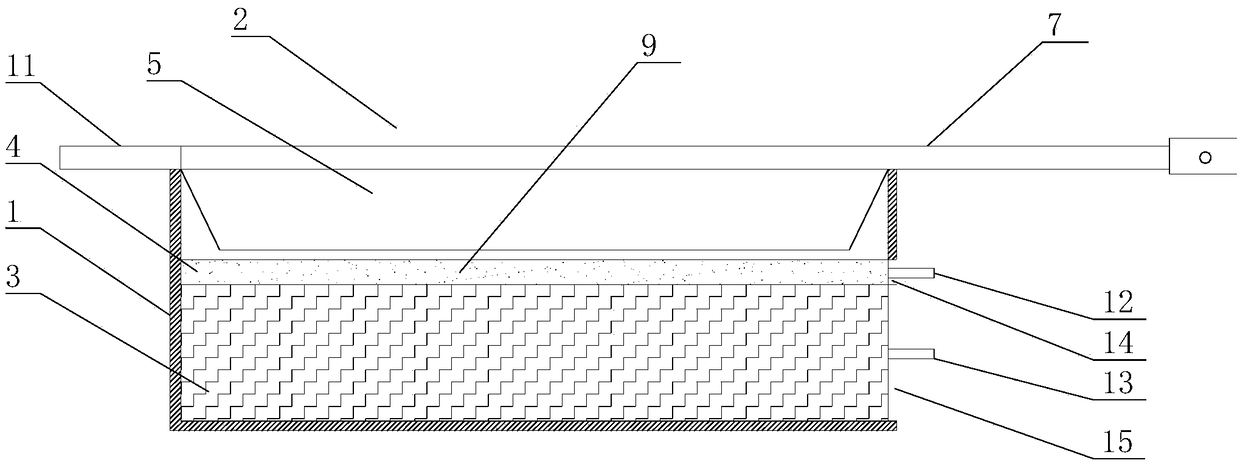

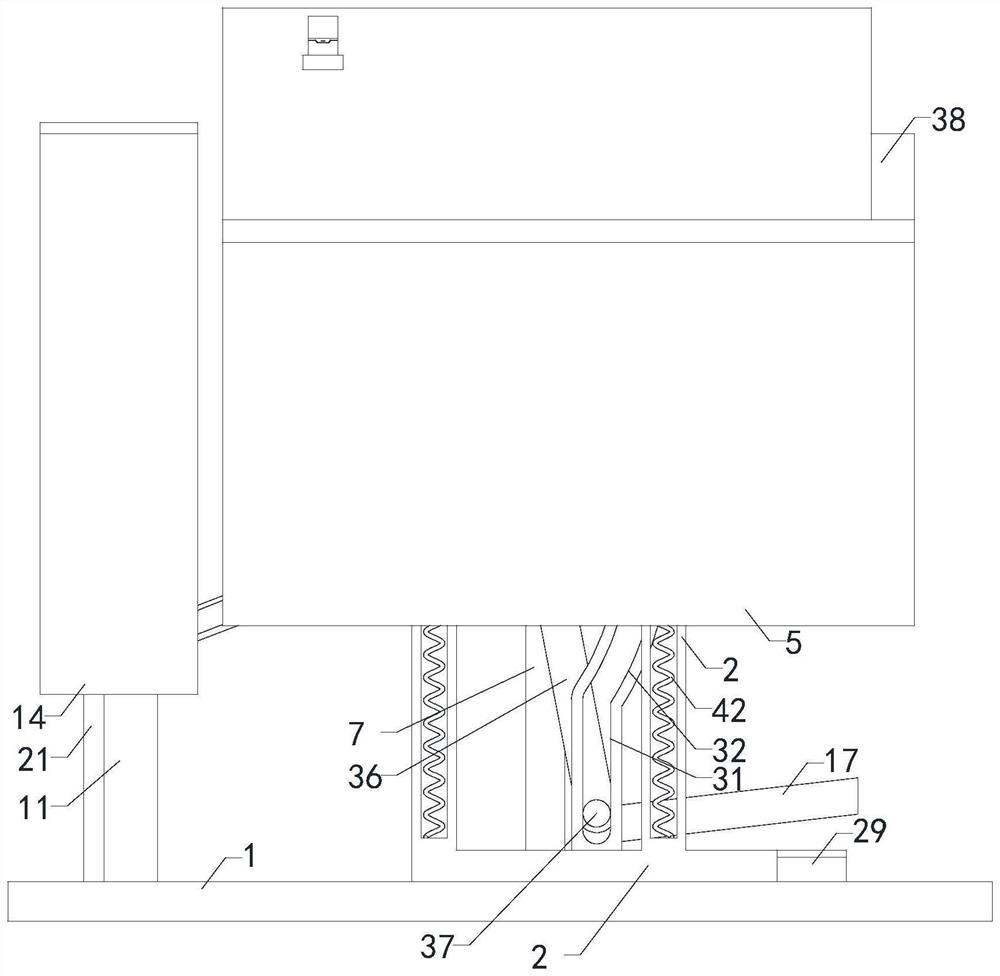

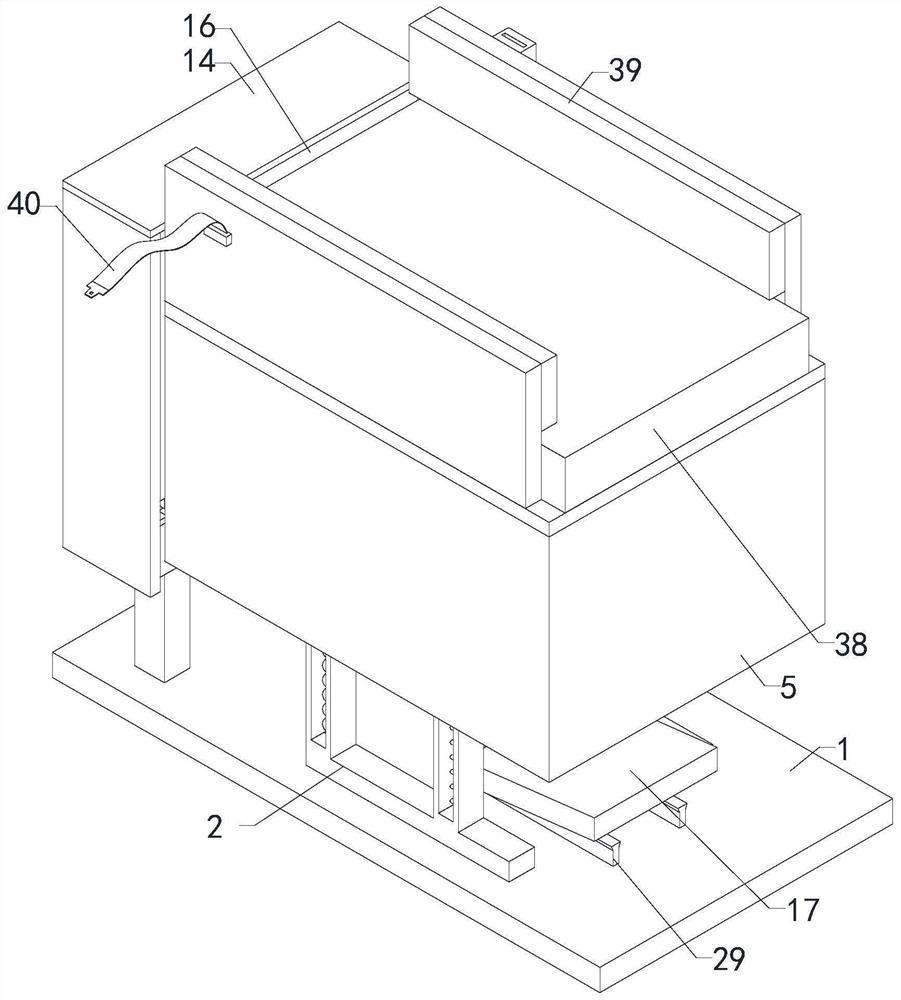

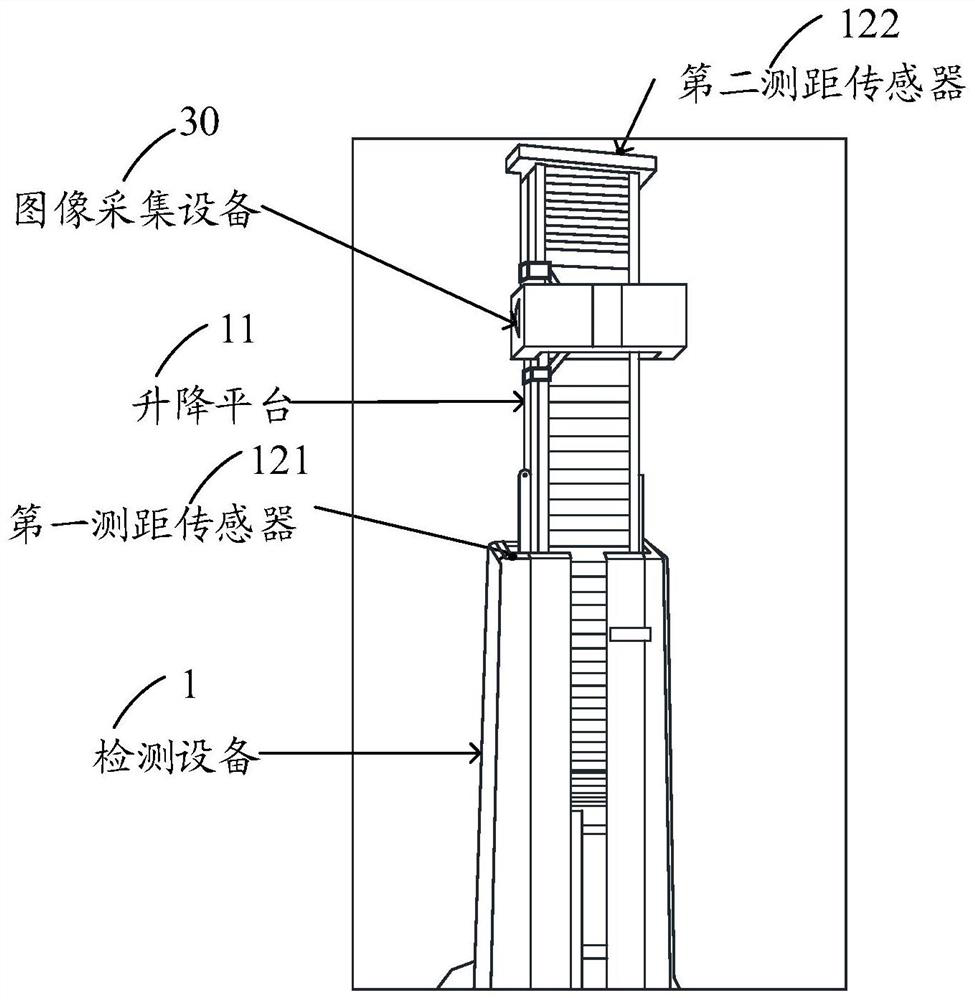

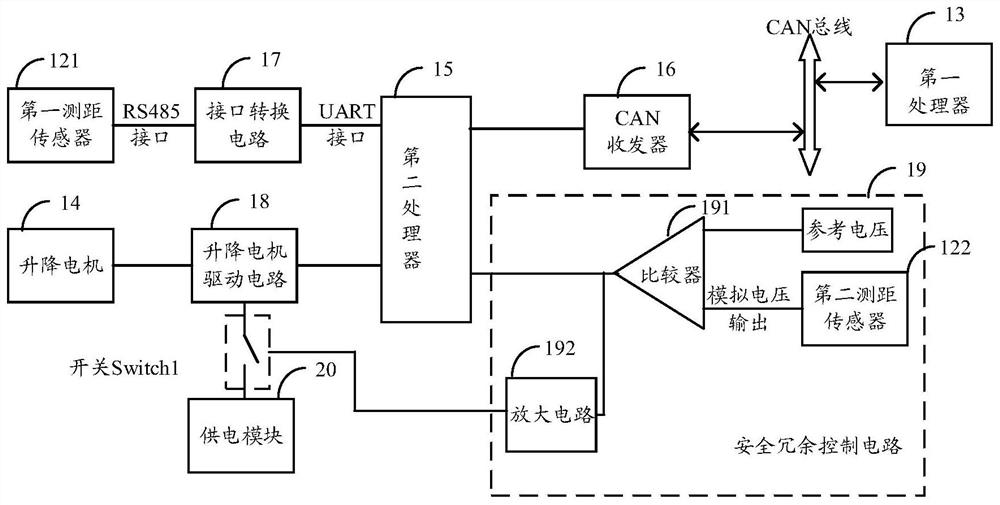

A control device and a detection device for a lifting platform of a detection device

ActiveCN111120827BAvoid touchingAddressed issues with hitting the ceilingTelevision system detailsSafety arrangmentsComputer hardwareElectric machinery

The embodiment of the present application discloses a control device for the lifting platform of the detection device, which is used to control the lifting platform of the detection device. The control device for the lifting platform of the detection device includes: a first ranging sensor, the first ranging sensor is set on The top of the detection device; the first processor connected to the first ranging sensor, the first processor is used to obtain the first ranging instruction, and control the first ranging sensor to measure and detect the top of the detection device according to the first ranging instruction The first distance between the obstacles directly above the device; the first processor is also used to obtain the first distance sent by the first ranging sensor, generate a raising instruction according to the first distance, and control the detection device according to the raising instruction The lifting motor drives the lifting platform from the current position to the target position, so that there is no contact between the lifting platform and the obstacle; the embodiment of the application also discloses a detection device.

Owner:JD DIGITS HAIYI INFORMATION TECHNOLOGY CO LTD

Hydraulic coordinated biomass sawing equipment

ActiveCN106078924BImprove crushing efficiencyReduced drying requirementsCircular sawsGrain treatmentsHydraulic cylinderCircular disc

The invention discloses hydraulically-synergistic biomass sawing equipment, and relates to a biomass raw material crushing machine and tool. The hydraulically-synergistic biomass sawing equipment comprises a hydraulic cylinder, a rack and an enclosing cover; the hydraulic cylinder and the rack are arranged in the enclosing cover, and a hydraulic column stretches out of the upper end of the hydraulic cylinder; a saw row assembly, a lifting rod, a left guide rail, a left guide rod, a right guide rail and a right guide rod are arranged in the equipment, the saw row assembly is composed of a lifting chassis, multiple small high-speed motors and multiple disc saw blades, the small high-speed motors are arranged on the lifting chassis, a rotation shaft of each small high-speed motor is provided with the corresponding disc saw blade, and the disc saw blades are horizontally arranged in a straight-line mode; the lower end of the lifting rod is connected with the middle of the lifting chassis, and the upper end of the lifting rod is connected to the upper end of the hydraulic column; when the hydraulically-synergistic biomass sawing equipment works, the saw row assembly is driven by the hydraulic column to do reciprocating lifting motion. According to the hydraulically-synergistic biomass sawing equipment, the hydraulically-synergistic saw row assembly is adopted, biomass raw materials are sawn through the disc saw blades which are arranged in the straight-line mode, the sawing speed is high, and the advantage of being high in crushing efficiency is achieved.

Owner:齐河智谷产业发展有限公司

Self-transportation detection platform based on sliding block detection

ActiveCN111929052AImprove detection efficiencyImprove the level of industrializationProgramme controlMachine part testingTrackwayMechanical engineering

The invention relates to a self-transportation detection platform based on sliding block detection. The self-transportation detection platform comprises a to-be-detected sliding block containing box,a first mechanical arm, a second mechanical arm, a plurality of sliding block running rails, a pressure column, a central control module, a surface detector and a plurality of sliding block conveyingbelts. According to the self-transportation detection platform, a to-be-detected sliding block is grabbed from the to-be-detected sliding block containing box and placed on the to-be-detected slidingblock running track through a manipulator, the pressure column presses the sliding block from top to bottom, the first section of track detects the integrity and smoothness of the ball in the slidingblock, the second section, the third section and the fourth section of tracks detect the bounce value and the working capacity of the sliding block, a surface detector is arranged at a tail end of thefourth section of track to detect the surface state of the sliding block, the detected sliding blocks are sorted according to the grabbing sequence of a mechanical arm, each detection result has a corresponding score, and the to-be-detected sliding blocks are classified according to grades according to final detection scores.

Owner:温州深信云电子科技有限公司

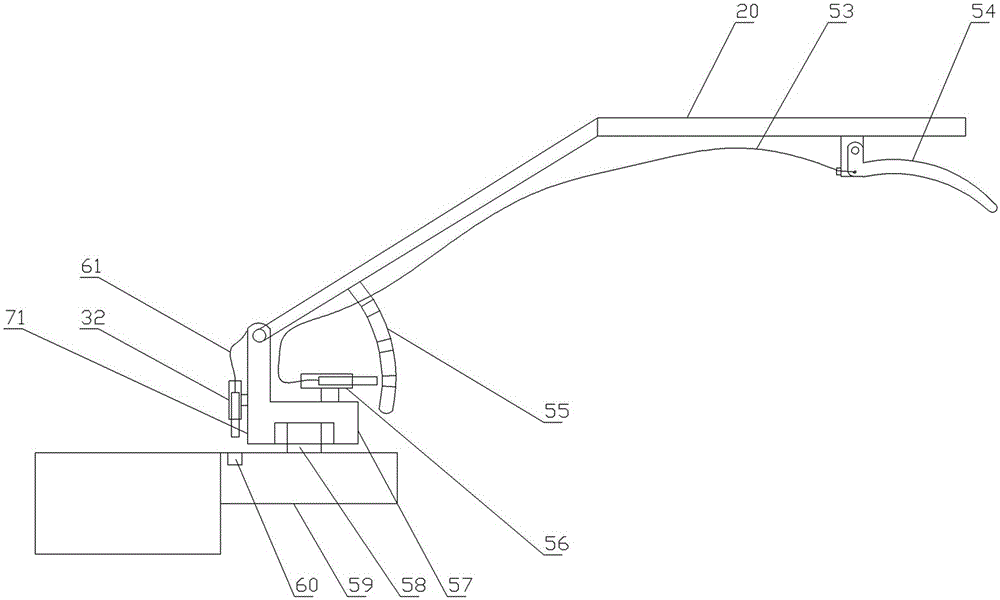

Field management motor force control device

InactiveCN104170549BImprove stabilityEasy to operateSoil-working equipmentsGuiding agricultural machinesClutch controlDrive shaft

The invention discloses a power control device of a field manage machine. The power control device comprises a supporting seat with a handlebar, and a traveling box and a ridging box which are in transmission connection with an engine gearbox are arranged on the supporting seat; the traveling box is in transmission connection with a travelling wheel through a transmission shaft; the ridging box is in transmission connection with a ridging plough through a transmission shaft; a speed gear lever and a forward and withdraw gear lever which are arranged on the travelling box as well as a ridging gear lever arranged on the ridging box are movably and respectively connected with a speed connecting lever, a forward and withdraw connecting lever and a ridging connecting lever; a clutch control unit in transmission connection with the gearbox is arranged on the handlebar; a speed control unit movably connected with the speed connecting lever and a forward and withdraw control unit movably connected with the forward and withdraw connecting lever are arranged on the travelling box; a ridging control unit movably connected with the ridging connecting lever is arranged on the ridging box; a steering unit is arranged at the joint of the handlebar and the supporting seat. By the arrangement, travelling distance is obviously shortened, and the problem that other components are easily touched due to long travelling distance is effectively solved.

Owner:SHANDONG FEIXIAN HUAYUAN AGRI EQUIP IND & TRADE CO LTD

Juicer featuring gap adjustment

InactiveCN100486494CProduction economyEliminates separate assembly stepsStrainersEngineeringMechanical engineering

The invention relates to a juicer used especially for squeezing citrus fruit. Said juicer comprises a pressing cone (36) that is rotatable about the cone axis (39) thereof and a strainer area (45) which is disposed above a receptacle (37) for squeezed juice, is assigned to the pressing cone (36), and is provided with a juice-permeable zone having a modifiable cross section of passage. In order to control the pomace content in the squeezed juice, the strainer member encompasses a first strainer area (78) that is provided with first passageways (79) and is arranged such that the position thereof relative to a second strainer area (45) which is provided with second passageways (54) can be modified while the cross section of passage of the strainer member can be modified by changing the position of the first (78) and second strainer area (45) relative to each other. A greater or smaller quantity of pulp can reach the squeezed juice by displacing the first strainer area (78) relative to the second strainer area (45).

Owner:BOSCH SIEMENS HAUSGERATE GMBH

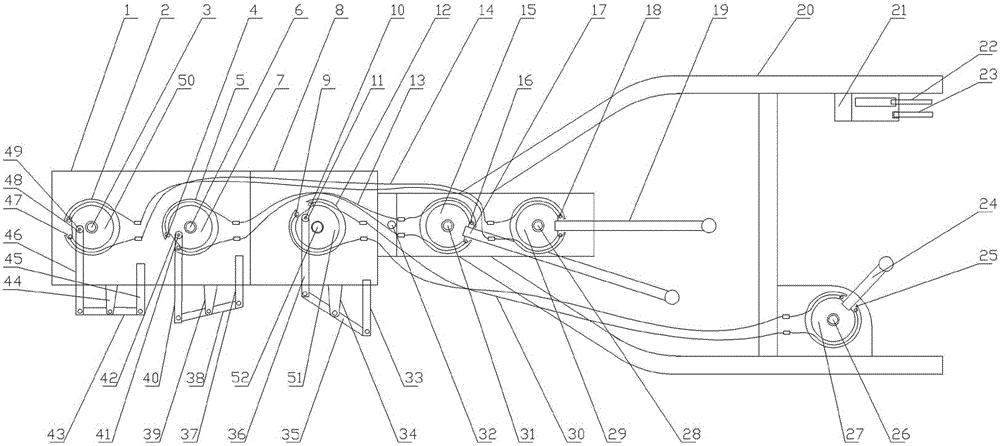

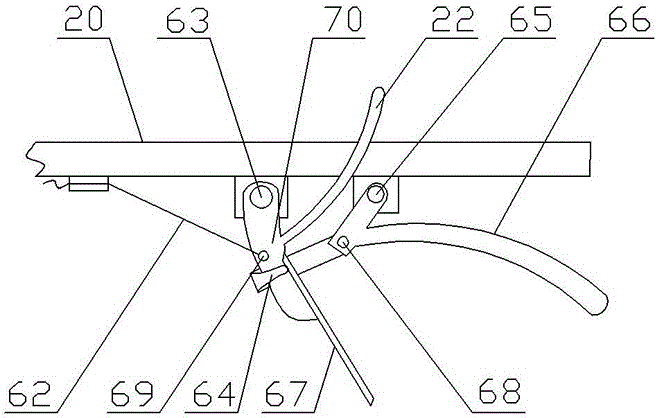

Quick pillow package feeding device

The invention discloses a quick pillow package feeding device applied to a pillow packing machine. The quick pillow package feeding device comprises an output assembly (22), wherein a feeding rack (16) is installed on one side of the output assembly, and a discharging frame (4) is arranged on the other side of the output assembly; a front feeding conveying assembly and a rear feeding conveying assembly are sequentially arranged on the feeding rack; a discharging rotating shaft corresponding to the position of the rear feeding conveying assembly is arranged on the discharging frame and above the output assembly; the discharging rotating shaft is connected with a discharging power source (1), and the discharging rotating shaft is composed of a left discharging rotating shaft (7) and a rightdischarging rotating shaft ( 8 ) which are arranged to be adjacent to each other; and pillow packages are fed into the left discharging rotating shaft and the right discharging rotating shaft one by one through a front flywheel and a rear flywheel step by step, and drop onto the output assembly through the rapid rotation of the left and right discharging rotating shafts. The pillow packages are fed and output quickly, and the pillow packages cannot be blocked or touched. The quick pillow package feeding device is simple in structure and convenient to operate, and is especially suitable for high-speed pillow packing machines and box packing machines.

Owner:WENZHOU XIAOJIANG MACHINERY TECH

Environment-friendly garment with non-touch trade mark

The invention relates to an environment-friendly garment with a non-touch trade mark. The environment-friendly garment comprises a garment body (1), wherein a piece of smooth rectangular cloth (2) is adhered to the inner side of the trade mark of the garment body (1) and wraps sewing threads on the inner side of the trade mark completely, the garment body (1) is made of fabric which comprises a pure wool texture layer and a wool and tencel blended yarn texture layer, and the pure wool texture layer and the wool and tencel blended yarn texture layer constitute an inner layer and an outer layer of the fabric respectively and are partially connected. According to the environment-friendly garment, the non-touch effect of the trade mark can be realized, the garment is environment-friendly, and wool cannot be damaged.

Owner:赵晓丰

Cold resistance clothing without trademark touch sense

InactiveCN103798998ANo touchAntifoulingProtective garmentSpecial outerwear garmentsTouch SensesTrademark

The invention relates to cold resistance clothing without trademark touch sense. The clothing comprises a clothing body (1), wherein the inner side of a trademark of the clothing body (1) is stuck with a smooth rectangular patch (2), the patch (2) wraps all sewing threads on the inner side of the trademark, the clothing body (1) is made of a fabric layer, and an elastic coating made of PU material wraps the periphery of the fabric layer. In such a way, the effect of no trademark touch sense can be realized by the clothing. The clothing has antifouling, waterproof, uvioresistant and cold-resistant properties.

Owner:龚新戈

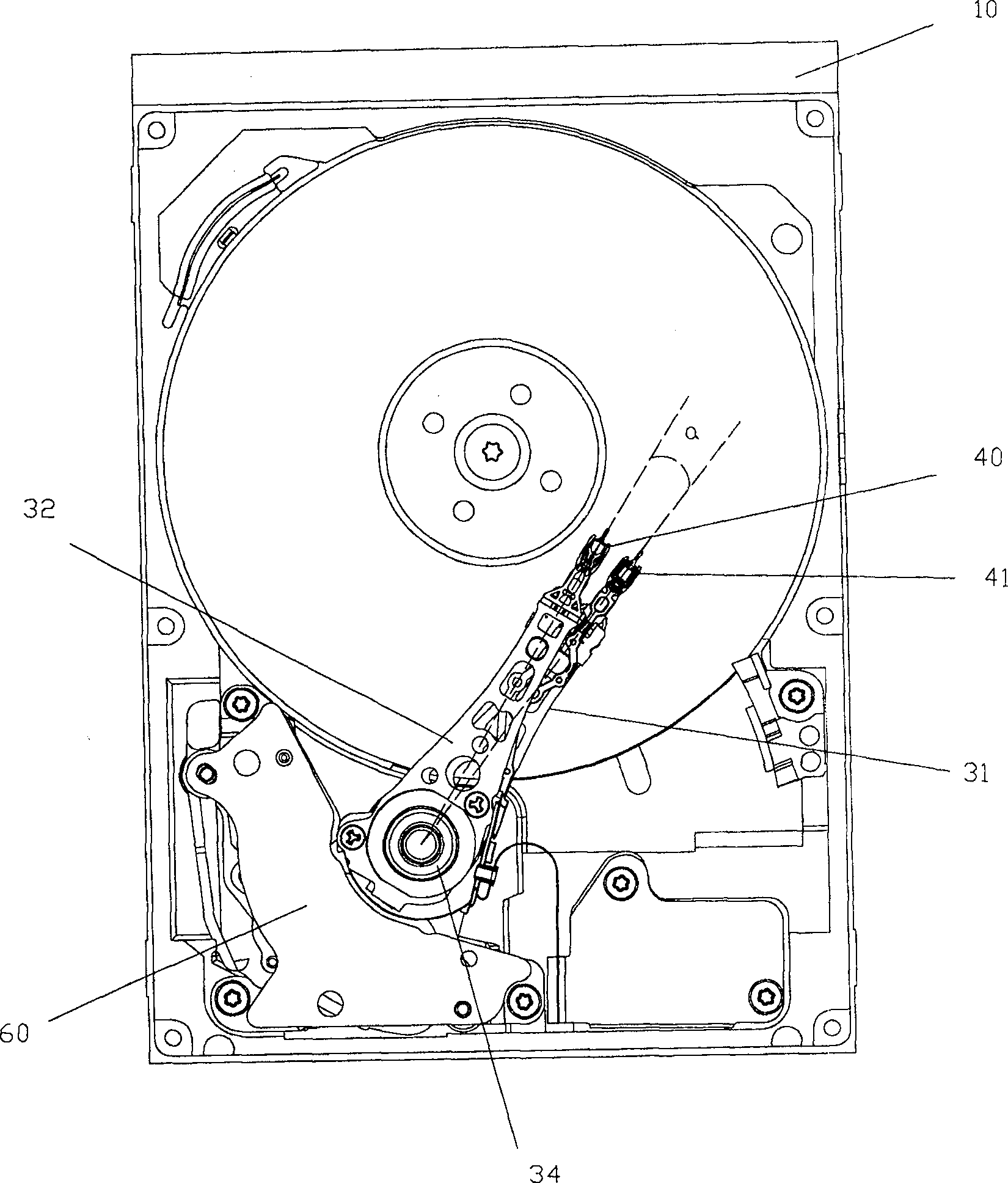

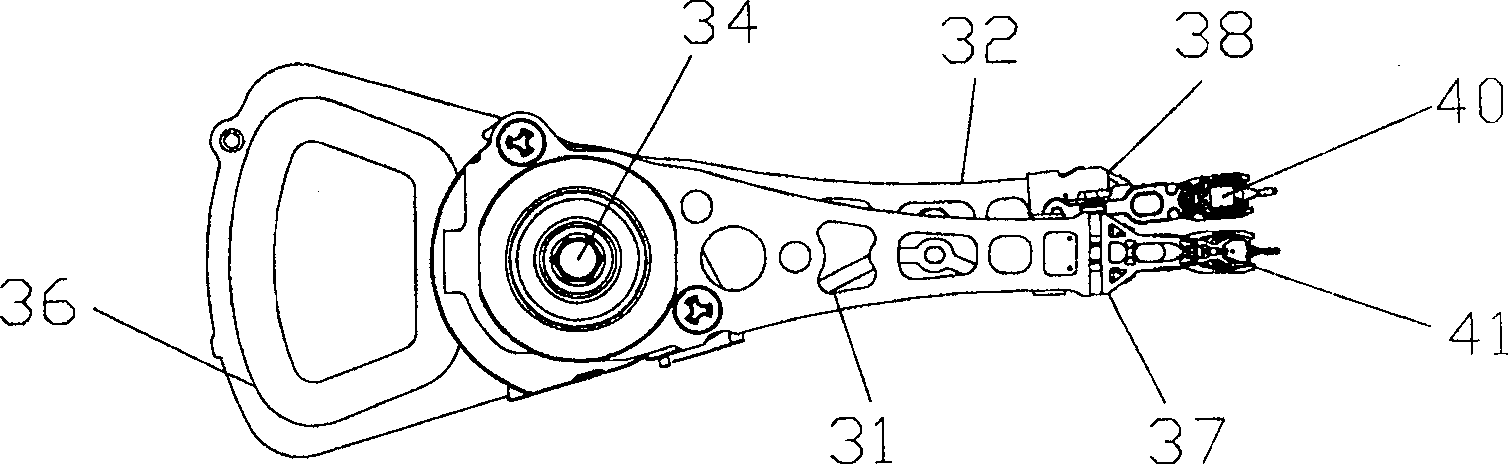

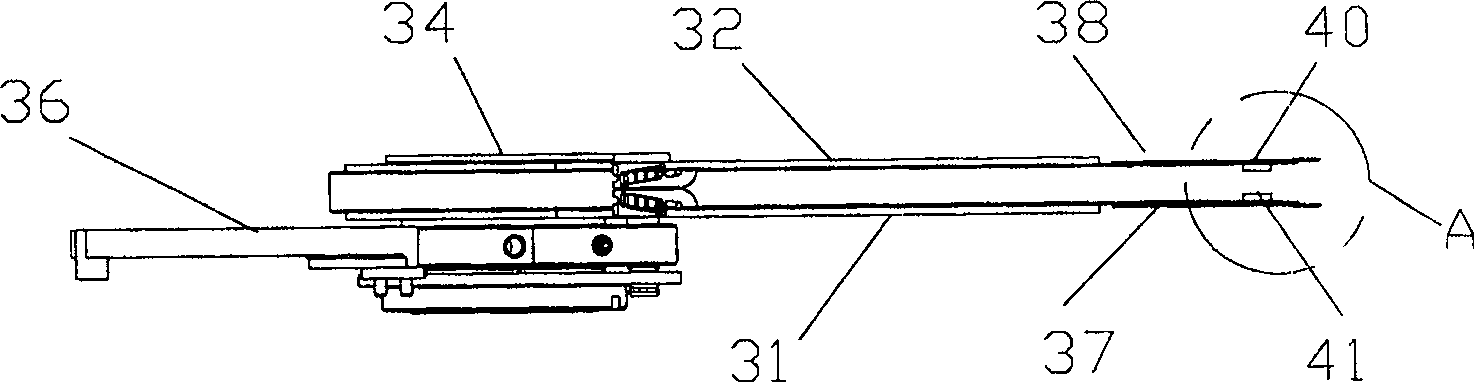

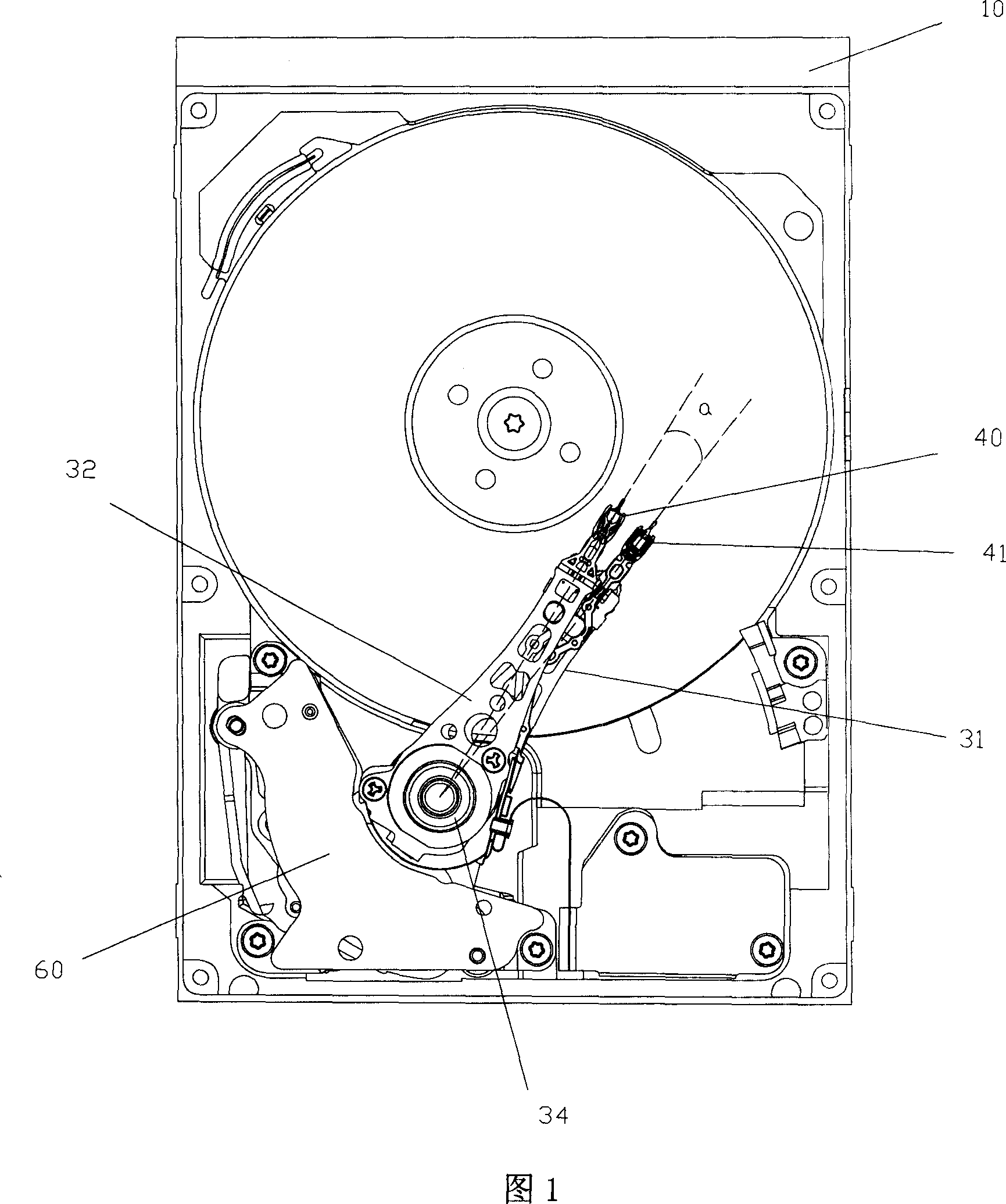

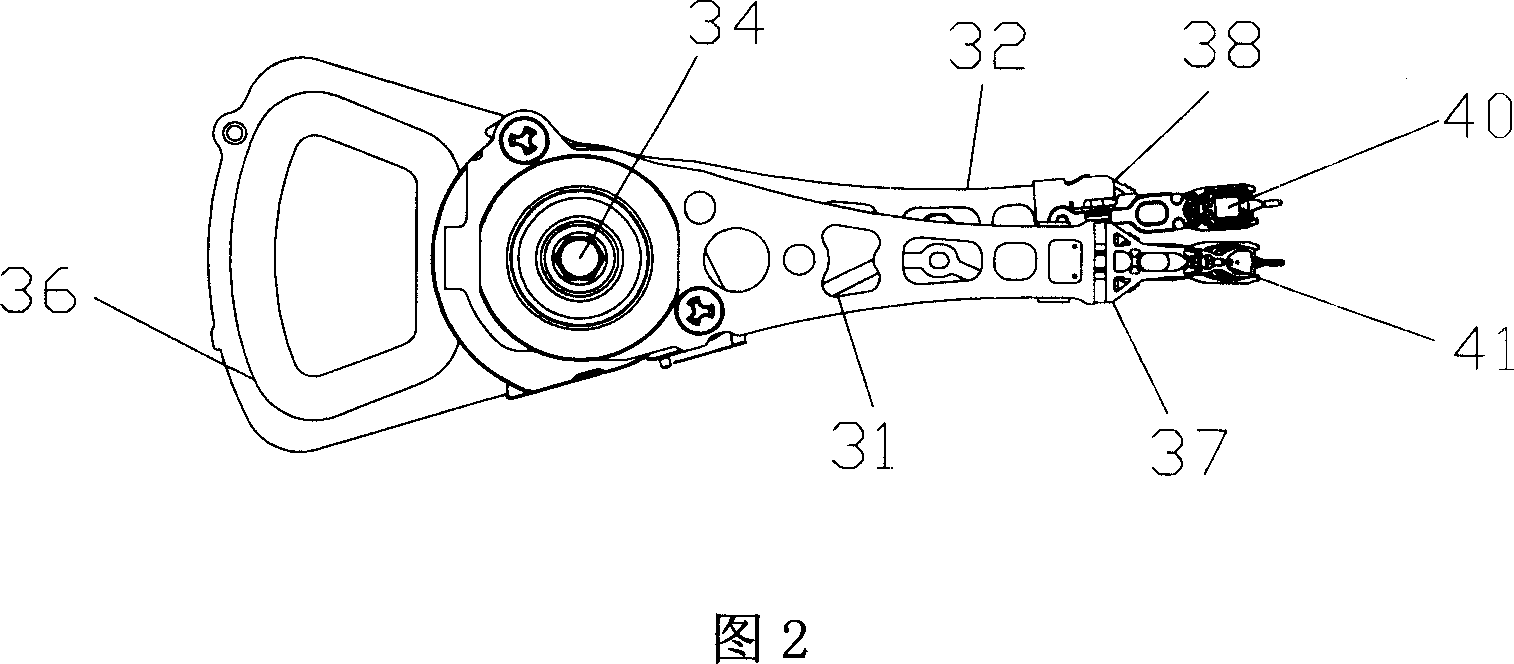

Magnetic head assembly and magnetic disc driver

InactiveCN100511429CNo touchAvoid damageDisposition/mounting of recording headsSupport for headsEngineeringCantilever

The invention relates to a new type of magnetic head assembly, comprising a pair of cantilevers, each cantilever end is connected with an elastic carrying arm, each end of the carrying arm is suspended with a magnetic head, and the magnetic heads at the ends of the two carrying arms are used to read and write the upper and lower sides of a magnetic disk The data. The magnetic heads on the carrying arm are staggered from each other. The present invention also relates to a disk drive using the magnetic head assembly, the opposing magnetic heads are offset so that the magnetic heads will not stick to each other and cause damage when the magnetic head assembly is installed.

Owner:YITUO SCI & TECH CO LTD SHENZHEN

Magnetic head assembly and magnetic disc driver

InactiveCN101067936ANo touchAvoid damageDisposition/mounting of recording headsSupport for headsLoading armEngineering

This invention relates to a new type of head component including a pair of cantilevers, the end of each of which is connected with an elastic loading arm and a head is hung on the end of the arm and heads at the ends of the two loading arms are used in reading data on up and down two sides of a disc and set staggeredly. This invention also discloses a disc drive using said head component.

Owner:YITUO SCI & TECH CO LTD SHENZHEN

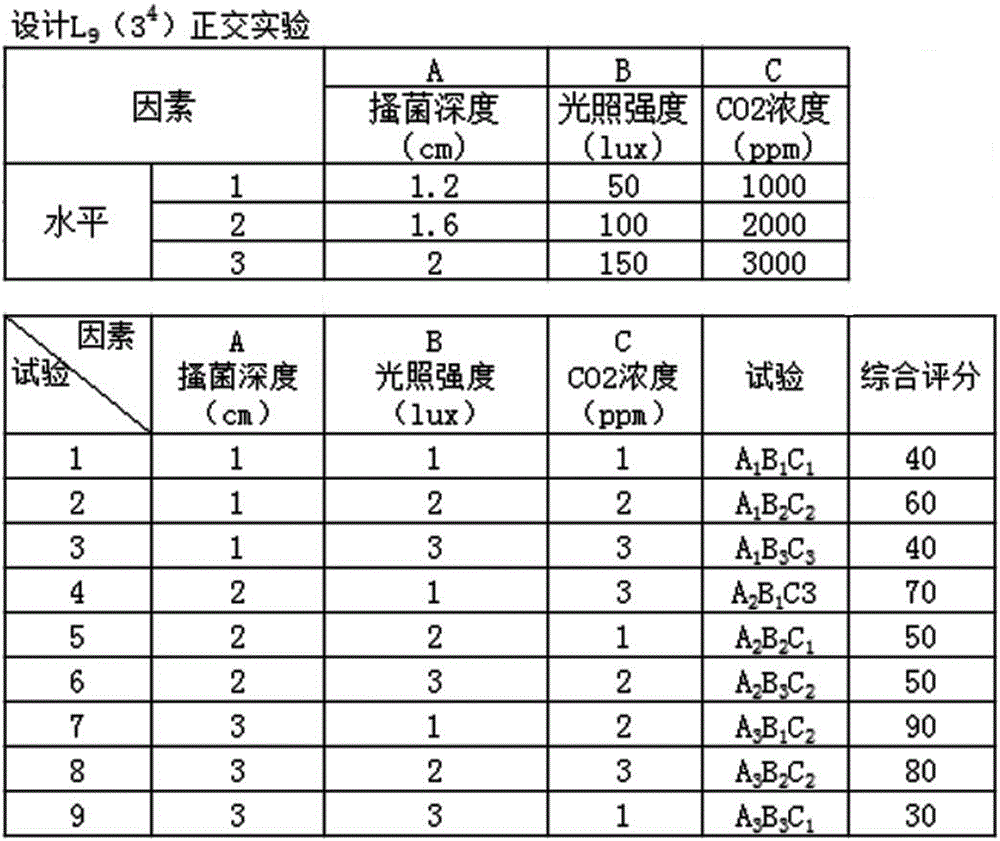

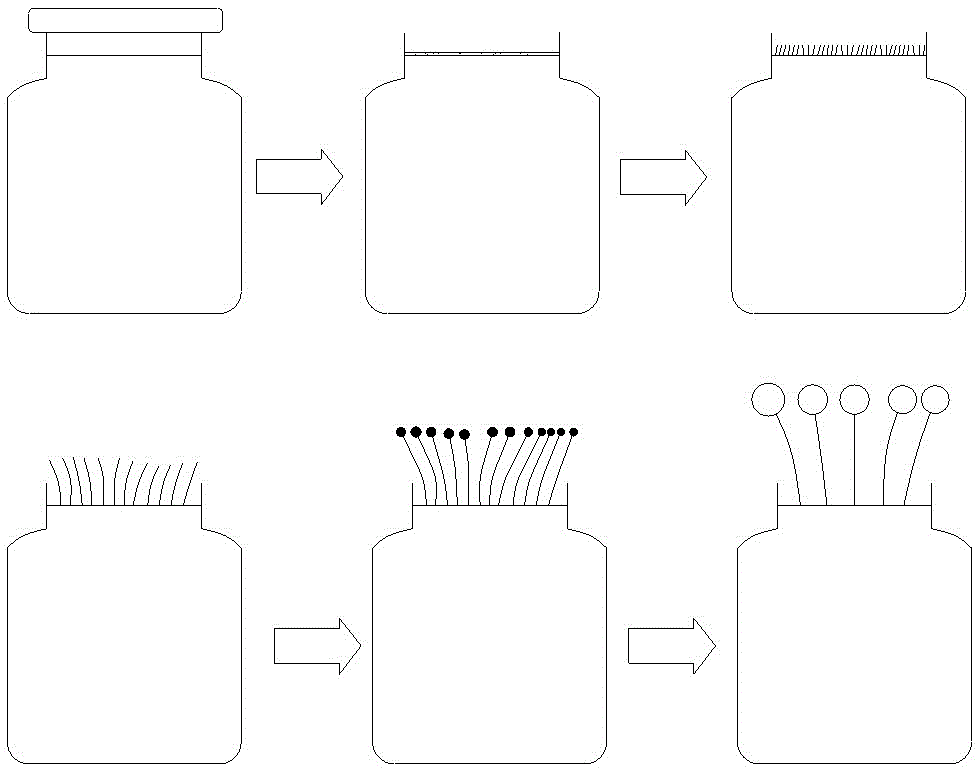

Method for controlling mushroom cap adhesion in edible mushroom fruiting process

The invention discloses a method for controlling mushroom cap adhesion in an edible mushroom fruiting process. Production factors of the edible mushroom fruiting process comprise: old strain block removing depth, illumination intensity and CO2 concentration; experiment data shows that the old strain block removing depth is increased to keep local humidity and CO2 concentration around an old strain block removing material surface; the heights of mushroom stems are increased through relatively high CO2 concentration and relatively less illumination; the mushroom stems are expanded outwards from a bottle mouth, so that the opportunity that one mushroom cap is in contact with the other mushroom cap is reduced; and an adhesion phenomenon does not occur when no contact between the mushroom caps exists.

Owner:SHANGHAI ZHINONG BIOLOGICAL SCI & TECH

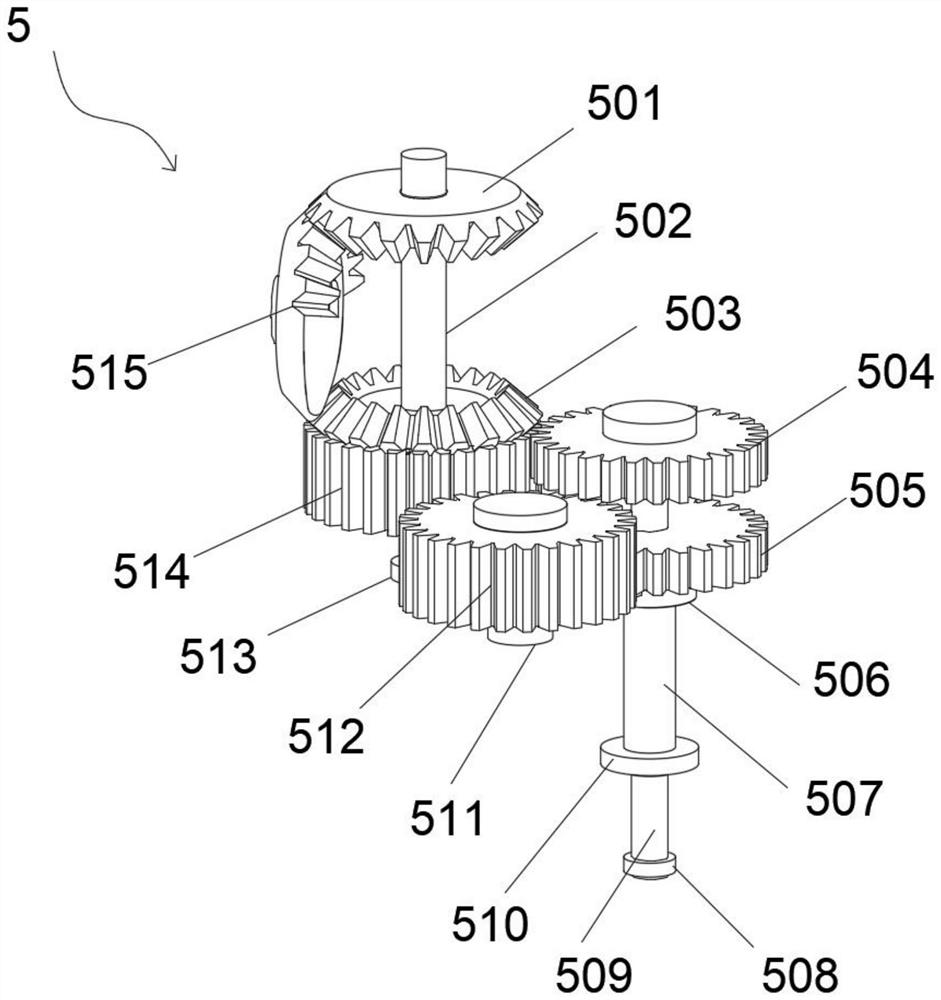

Beef cattle breeding feed processing and drying device

InactiveCN114018016AImprove the mixing effectDry evenly and fullyFeeding-stuffDrying chambers/containersGear wheelElectric machinery

The invention discloses a beef cattle breeding feed processing and drying device which comprises a drying box and a driving box fixed to the upper end of the drying box. A stirring and drying mechanism is arranged in the drying box, a transmission mechanism for rotating the stirring and drying mechanism is arranged in the driving box, and a driving motor drives a half-face bevel gear to rotate. When the half-face bevel gear rotates by a circle, the rotating direction of the second thick gear changes once, and due to the fact that the second thick gear is meshed with the first thick gear, the second thin gear is meshed with the upper half portion of the second thick gear, and the first thin gear is meshed with the lower half portion of the first thick gear, the rotation directions of the second thin gear and the first thin gear are always opposite, so that the rotation directions of the second thin gear and the first thin gear are changed once when the half-face bevel gear rotates for one circle, namely, the second thin gear and the first thin gear are subjected to clockwise rotation and anticlockwise rotation once when the half-face bevel gear rotates for one circle, and the stirring effect is effectively improved.

Owner:湖南振鑫农业科技有限公司

A sublimation transfer printing process for natural fabric or rayon

InactiveCN103898778BNo touchSoft touchTransfer printing processVegetal fibresPulp and paper industryPre treatment

Owner:中山市粤漳科技有限公司

Comfortable garment with trademark free of touch

The invention relates to a garment, in particular to a comfortable garment with a trademark free of touch. The garment comprises a garment body (1) and is characterized in that a piece of smooth rectangular cloth (2) adheres to the inner side of the trademark of the garment body (1) and all wraps stitches on the inner side of the trademark, the garment body (1) is made of a fabric, and the fabric is formed by warp yarn and weft yarn by drifting interweaving, one of the warp yarn and the weft yarn is elastic wrap yarn, and the elastic wrap yarn is composed of spandex yarn located at the center and a plurality of pieces nylon low stretch yarn wrapping the spandex yarn. The stitches on the inner side of the trademark cannot be in direct contact with the skin of the human body, and accordingly the effect of being free of trademark touch is achieved. The garment is extremely high in comfort and free movement effect.

Owner:翟文卓

Embroidering fabric and manufacturing method thereof

The invention relates to an embroidering fabric and a manufacturing method thereof, and belongs to the field of embroidery. The manufacturing method comprises the following steps that a fabric is dyedand subjected to first-time drying to obtain an initial fabric, the surfaces of embroidery threads are smeared with wax liquid, then the initial fabric is embroidered and smeared with a smoothing agent, and secondary drying is conducted on the initial fabric. The smoothing agent is prepared from, by weight, 8-10 parts of starch grafting sodium acrylate, 4-5 parts of organic silicon rubber, 2-3 parts of amino silicone microemulsion, 4-5 parts of lauric acid containing ester quaternary ammonium salt, 1.5-2 parts of imidazoline type surfactant, 1.5-2 parts of triethylene diamine and 50-60 partsof water through mixing. The preparation method is simple and convenient to conduct, the soft and smooth characteristics of the embroidering fabric can be maintained for a long time, the pilling or fluffing phenomenon can be avoided, and the embroidering fabric is especially suitable for the manufacturing of embroidery clothing of the Miao nationality and the Dong nationality. The embroidering fabric manufactured by the manufacturing method is soft and smooth, and after the embroidering fabric is in contact with the skin, no uncomfortable touch feeling is generated.

Owner:贵州凯里经济开发区鑫田民族服饰工艺品发展有限公司

Trademark touch-free black-out cloth fabric clothing

InactiveCN103798995ANo touchImprove privacyProtective garmentSpecial outerwear garmentsBlack outSurface layer

The invention relates to trademark touch-free black-out cloth fabric clothing, which comprises a clothing body (1). A piece of smooth rectangular cloth (2) is pasted to the inner side of a trademark of the clothing body (1); stitches of the inner side of the trademark are completely wrapped by the cloth (2); the clothing body (1) is made of fabric; the fabric comprises a surface layer, a lining layer and a middle layer connected between the surface layer and the lining layer; the surface layer and the lining layer form a whole by interweaving warp yarns and weft yarns. A trademark touch-free effect can be achieved by the trademark touch-free black-out cloth fabric clothing provided by the invention. The trademark touch-free black-out cloth fabric clothing provided by the invention has a shading effect.

Owner:张英

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com