Juicer featuring gap adjustment

A juicer and fruit juice technology, which is applied to household machinery for filtering food, household appliances, kitchen appliances, etc., can solve the problem that the extrusion cone cannot be adjusted, and achieve the effect of precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

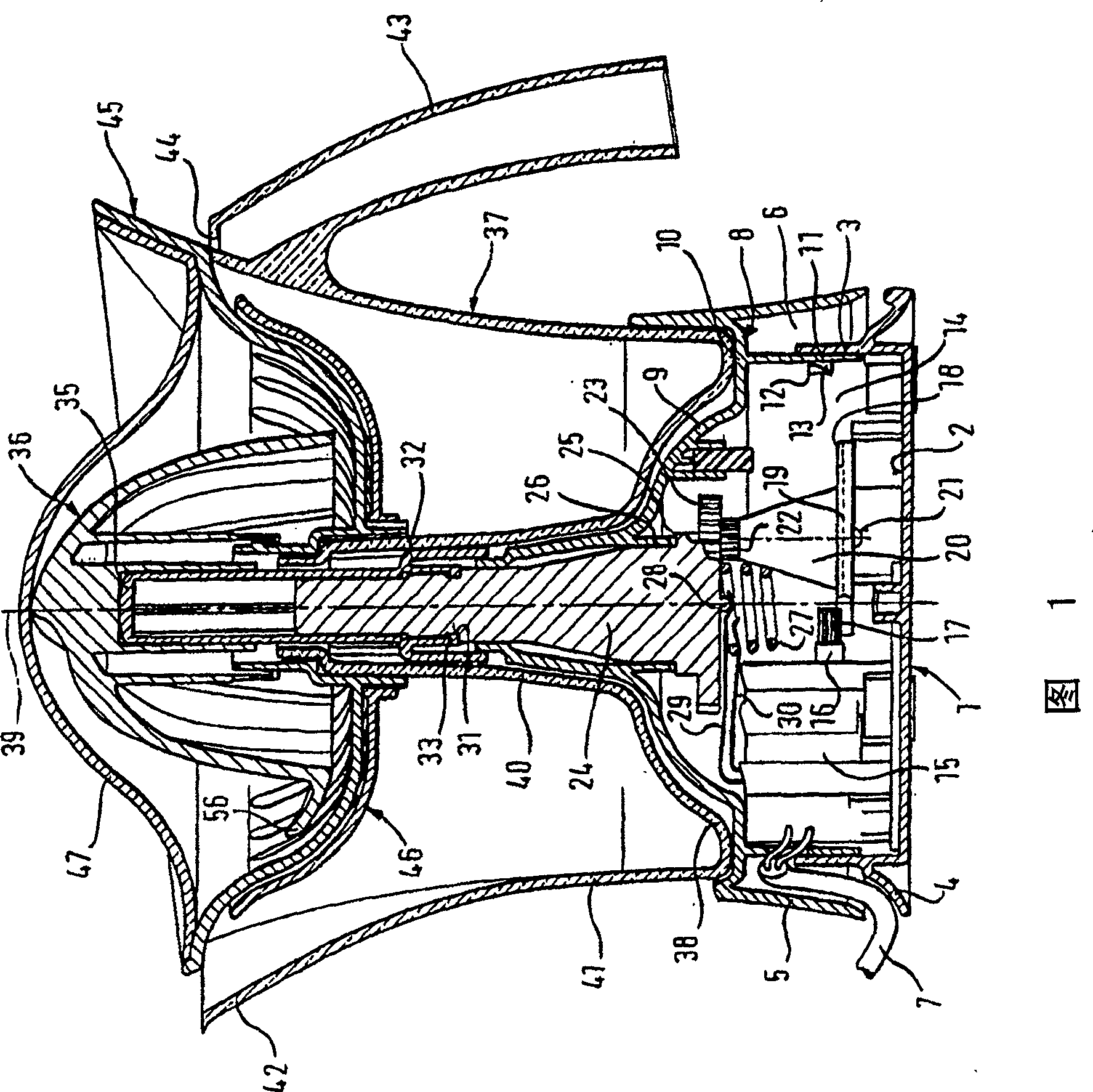

[0025] The juice extractor shown in section in FIG. 1 has a cup-shaped housing base 1 with a disk-shaped base 2 and a cylindrical side wall 3 surrounding the edge of the base 2 . Formed on the side wall 3 is a groove-shaped support edge 4 that surrounds the housing base 1 and is directed radially outward from the side wall and has an arc-shaped cross-section. The support edge 4 together with a stop 5 delimits an annular groove 6 for receiving an electrical connection cable 7 . The baffle 5 is formed by a wall section formed on a dome cover 8 . The cover plate 8 has a spherical top surface 9 , on whose horizontally extending edge section 10 the wall sections forming the barrier 5 adjoin. This wall section is arranged to extend substantially vertically and has a slightly conical outer surface. An annular cylindrical side wall 11 corresponding to the annular cylindrical side wall 3 extends vertically downward from the lower part of the annular edge section 10 . The side walls ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com