Electrodes for RRAM memory cells

A technology of memory cells and anti-oxidation layers, applied in the field of thin film resistance memory devices, can solve the problems of inappropriate manufacturing of submicron and large memory devices, low reliability, low cost efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

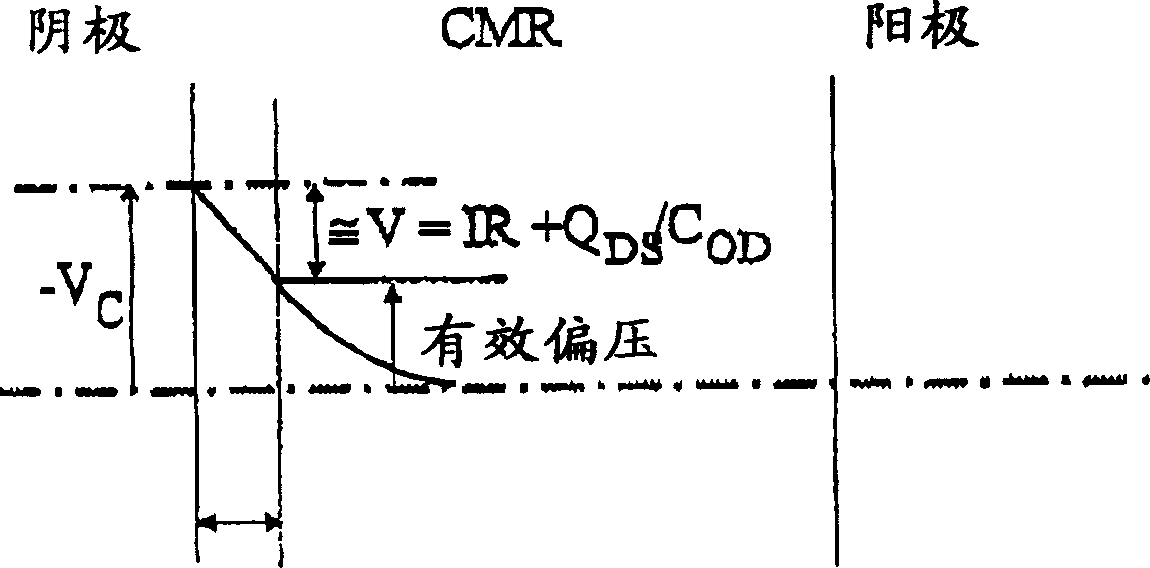

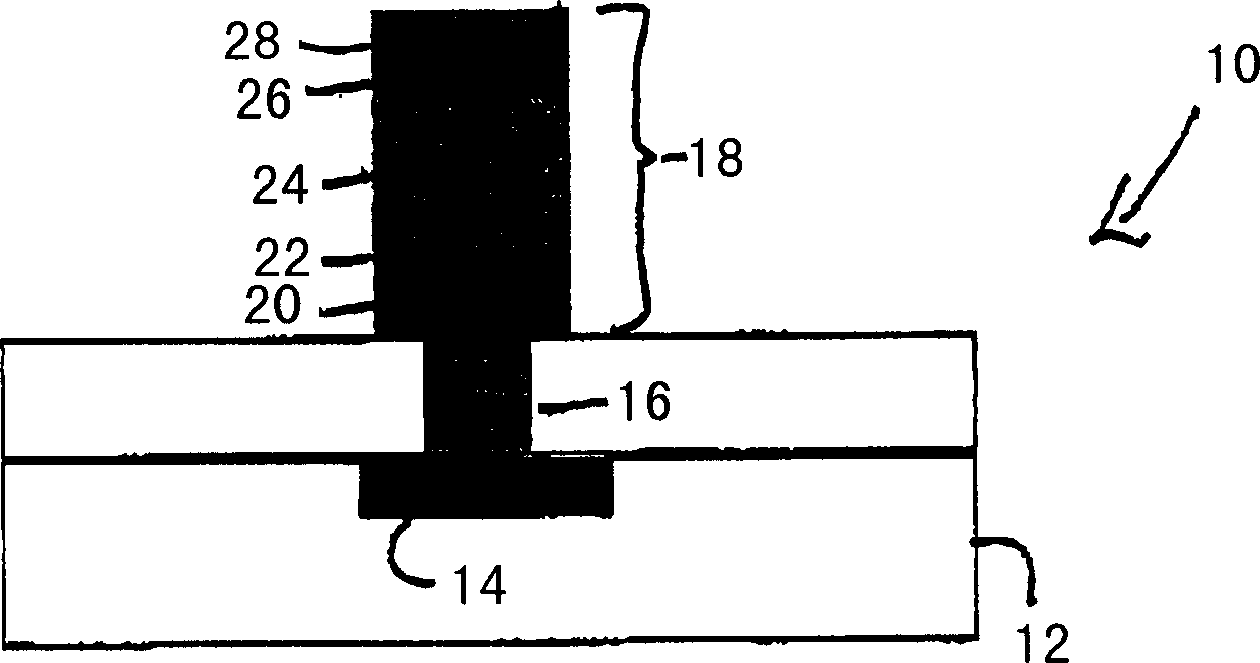

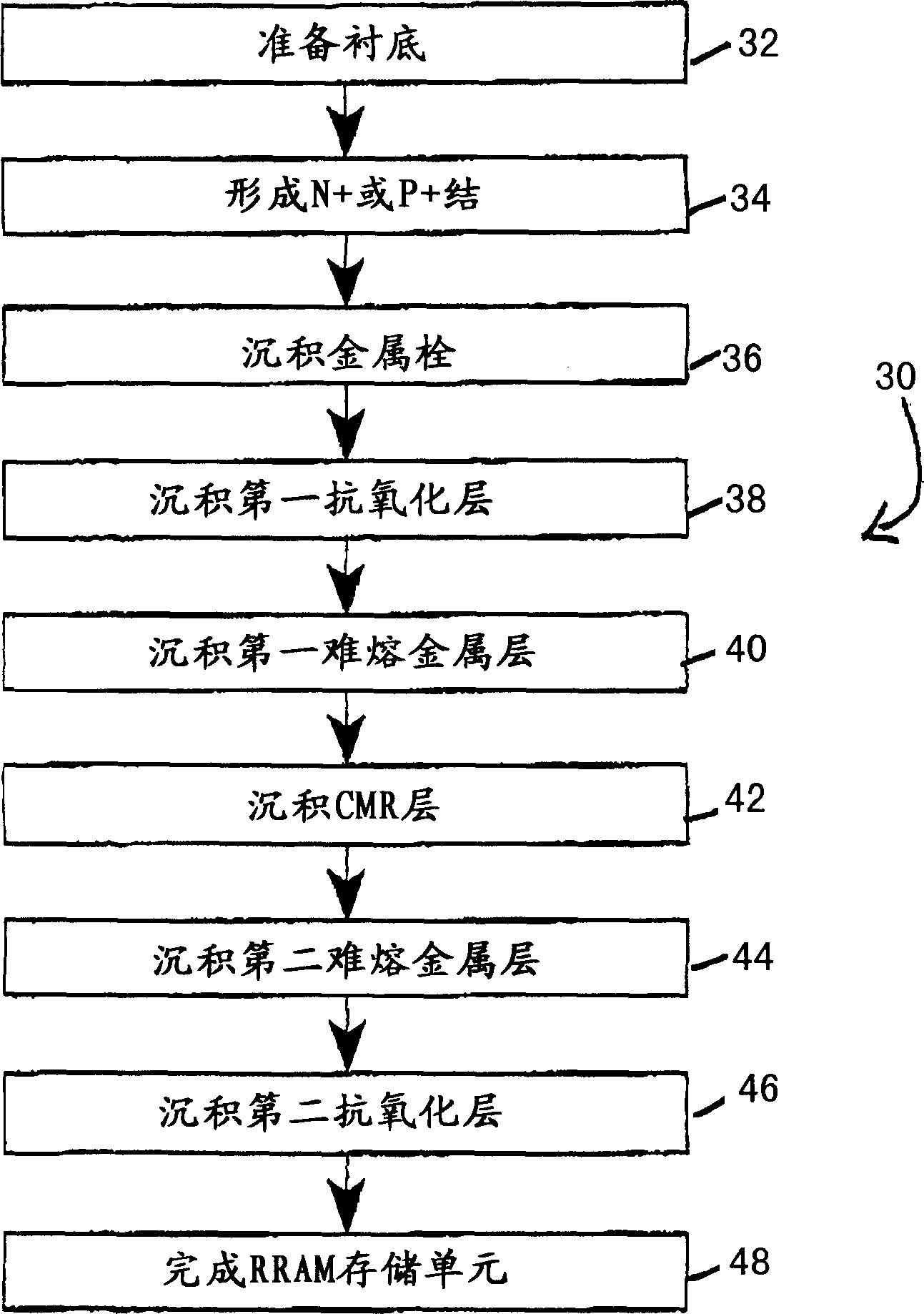

[0012] Experimental data demonstrates that during programming, the resistivity of the RRAM material near the cathode transitions to a high-resistivity state, while near the anode transitions to a low-resistivity state. The transition in resistivity occurs at the instant a narrow voltage pulse is applied to the device, which causes a voltage drop near the cathode. The change in resistivity requires a clear onset voltage. Experiments also found that the material requires a certain oxygen content, because when the oxygen content is too low, there is no change in resistivity.

[0013] If the electrode of the RRAM memory cell does not have oxidation resistance, the electrode will be oxidized during temperature treatment in the manufacturing process, or gradually oxidized by heat generated by current-voltage during normal operation. As the electrode oxidizes, oxygen diffuses from the RRAM material into the electrode, resulting in oxygen-deficient regions. Both oxidized electrodes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com