Preparation method for aluminum-coated nickel-cobalt lithium manganite and lithium battery

A technology of lithium nickel cobalt manganese oxide and nickel hydroxide lithium cobalt manganese oxide, which is applied in the field of material preparation, can solve the problems of reduced gram capacity of ternary materials, poor stability of ternary materials, and reduced electrochemical performance, so as to improve Effects of cycle stability and active material utilization, long service life, and reduction in gram capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of aluminum-coated nickel-cobalt-manganese lithium manganese oxide provided in this example involves stirring and mixing the spherical or quasi-spherical nickel-cobalt-manganese hydroxide precursor and lithium hydroxide or lithium carbonate in an aqueous solution. The NETZSCH ball mill performs wet ball milling, and then produces primary particles by spray drying. The primary particles are spherical nickel cobalt manganese hydroxide, and the particle size range of spherical nickel cobalt manganese hydroxide is between 1 μm and 20 μm. After high temperature treatment at 920°C to 1050°C under air or oxygen atmosphere, and heat preservation for 12 hours to 20 hours, spherical nickel cobalt lithium manganese oxide is obtained. Then the nickel cobalt lithium manganese oxide ternary material made above and Al 2 o 3Dry ball milling with a planetary ball mill for 10 minutes to 60 minutes, then dry at a low temperature of 40°C to 80°C, and finally sinter ...

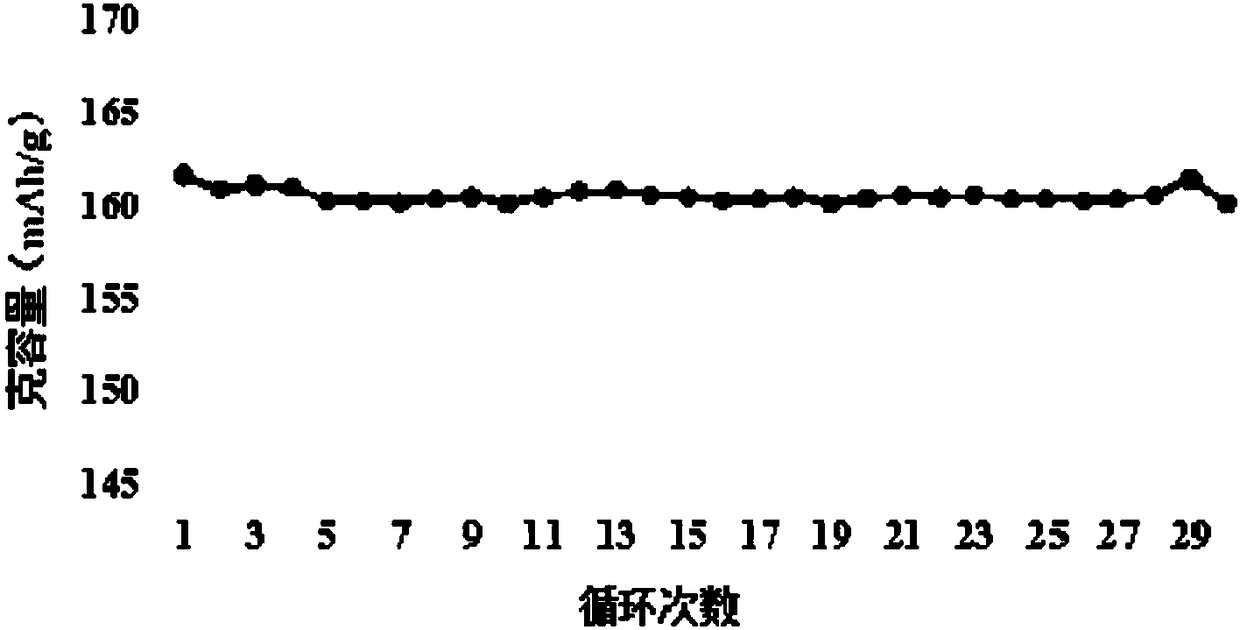

no. 1 example

[0049] 1400g of nickel hydroxide, cobalt manganese and 591.2g of lithium carbonate were added to 6000g of deionized water and stirred for 2h to 6h to obtain a uniformly mixed suspension. Pour the suspension into a Netzsch ball mill, set the speed of the ball mill to 3000r / min to 4000r / min, and the ball milling time to 3.5h to 6h. The suspension after the wet ball milling is driven into a spray drying equipment by a peristaltic pump for drying to obtain a black powder, namely spherical nickel cobalt manganese hydroxide. The obtained material (spherical nickel cobalt manganese hydroxide) is placed in an atmosphere muffle furnace for primary sintering, and the temperature is raised to 500°C at a constant 10°C / min in an air or oxygen atmosphere, and the temperature is kept constant for 5h to 10h, and then at a constant temperature of 20°C / min to raise the temperature to 950°C, keep the temperature constant for 10h to 16h, and cool naturally to obtain the nickel-cobalt-lithium-man...

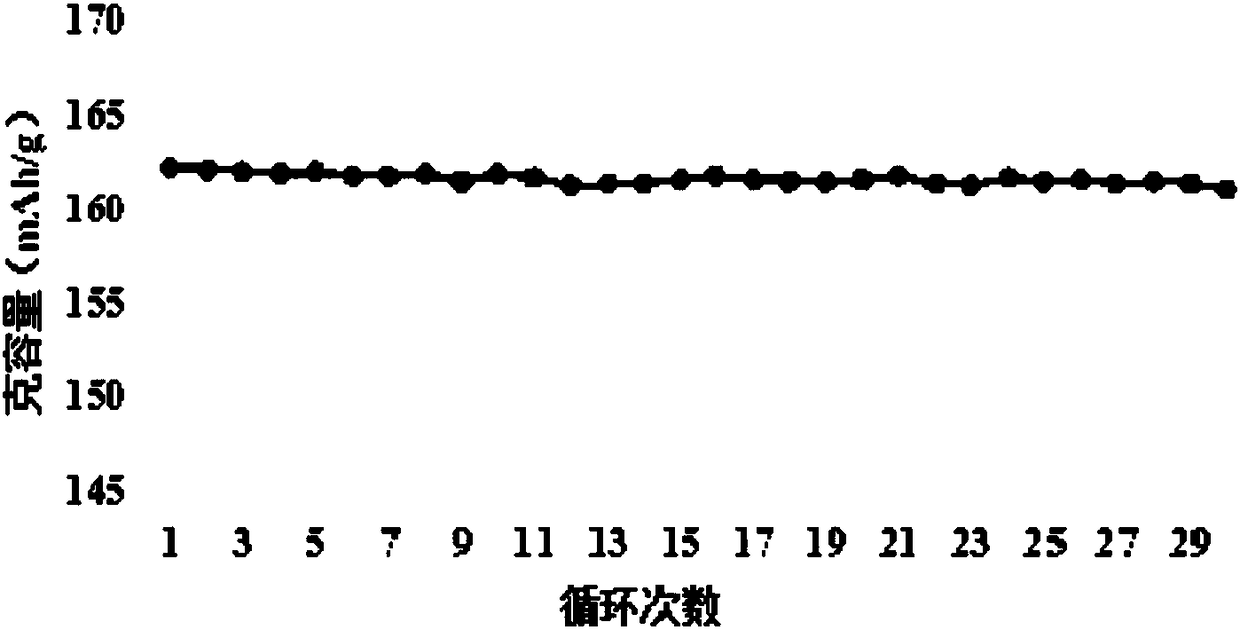

no. 2 example

[0054] Add 671.1g of lithium hydroxide to 6000g of deionized water to form a lithium hydroxide aqueous solution, then add 1400g of nickel hydroxide, cobalt and manganese, and mix and stir for 2h to 6h to obtain a uniformly mixed suspension. Pour the suspension into a Netzsch ball mill, set the speed of the ball mill to 3000r / min to 4000r / min, and the ball milling time to 3.5h to 6h. The suspension after the wet ball milling is driven into a spray drying equipment by a peristaltic pump for drying to obtain a black powder, namely spherical nickel cobalt manganese hydroxide. The obtained material (spherical nickel cobalt manganese hydroxide) is placed in an atmosphere muffle furnace for primary sintering, and the temperature is raised to 500°C at a constant 10°C / min in an air or oxygen atmosphere, and the temperature is kept constant for 5h to 10h, and then at a constant temperature of 20°C / min to raise the temperature to 950°C, keep the temperature constant for 10h to 16h, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com