Membrane material for lithium sulfur battery positive electrode

A lithium-sulfur battery and membrane material technology, applied in the field of electrochemical batteries, can solve the problems of capacity loss, corrosion of metal lithium negative electrode, reduction of battery charging and discharging coulomb efficiency, etc., and achieve the effects of reducing corrosion effect, inhibiting dissolution and superior performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

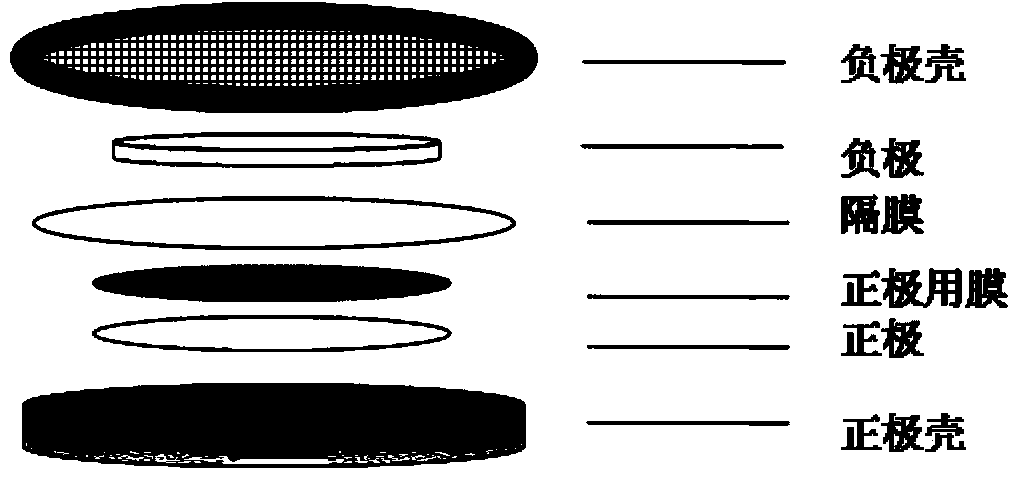

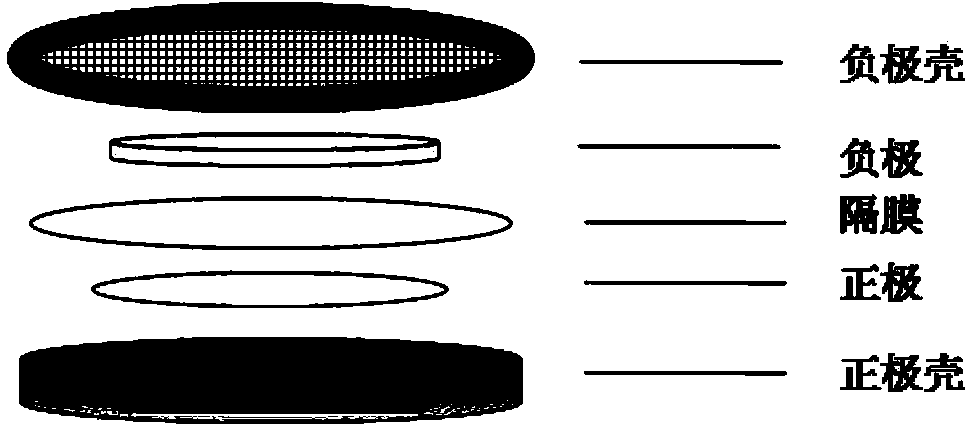

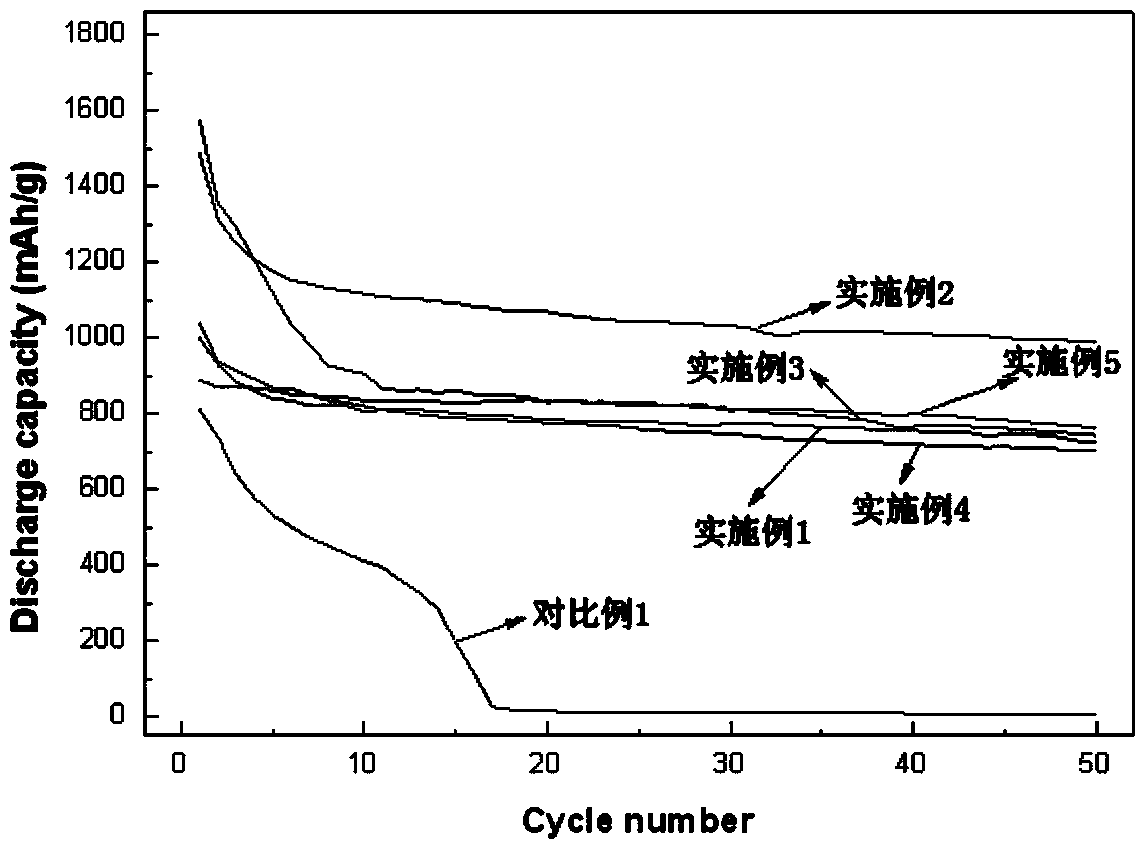

Embodiment 1

[0046] In this embodiment, the preparation method of the membrane material for the positive electrode of the lithium-sulfur battery comprises the following steps:

[0047] (1) Membrane precursor material pretreatment: Arrange the membrane precursor material cotton in ethylene glycol solution and soak for 9 hours, wash with distilled water 3 times, place in a vacuum drying oven, and vacuum dry at 70°C for 6 hours for later use;

[0048] (2) Take the filling material acetylene black, the stabilizer nano-vanadium pentoxide and the binder A polyvinylidene fluoride solution (PVDF, 15wt%, the solvent is NMP), and the mass ratio of the filling material to the binder A is 1: 2. The quality of the stabilizer is 10% of the mass of the filling material. After the slurry is adjusted, the slurry is evenly scraped on the pretreated film precursor material in step (1). The thickness of the scraped slurry is 0.05mm, and it is placed in a vacuum In a drying oven, vacuum dry at 50°C for 24 hour...

Embodiment 2

[0055] In this embodiment, the preparation method of the membrane material for the positive electrode of the lithium-sulfur battery comprises the following steps:

[0056] (1) Membrane precursor material pretreatment: Arrange the conductive carbon fibers of the membrane precursor material in ethanol solution for 8 hours, wash with distilled water for 3 times, place in a vacuum drying oven, and vacuum dry at 100°C for 2 hours for later use;

[0057] (2) Take the filling material superconducting carbon black, the stabilizer nano zinc oxide and the binder A carboxymethyl cellulose solution (CMC, 10wt%, the solvent is distilled water), the mass ratio of the filling material to the binder A is 1 : 2. The quality of the stabilizer is 5% of the quality of the filling material. After the slurry is adjusted, the slurry is evenly scraped on the pretreated film precursor material in step (1), and the thickness of the scraped slurry is 0.10mm. In a vacuum drying oven, vacuum dry at 50°C f...

Embodiment 3

[0064] In this embodiment, the preparation method of the membrane material for the positive electrode of the lithium-sulfur battery comprises the following steps:

[0065] (1) Membrane precursor material pretreatment: Arrange the membrane precursor material polyester in isopropanol solution and soak for 10 hours, wash with distilled water for 3 times, place in a vacuum drying oven, and vacuum dry at 60°C for 8 hours for later use;

[0066] (2) Take the filling material superconducting graphite, the stabilizer nano-titanium dioxide and the binder A polytetrafluoroethylene emulsion (PTFE, 60wt%, purchased from Xinxiang Heluolida Power Material Co., Ltd.), the filling material and the binder The mass ratio of A is 1:10, and the mass of the stabilizer is 1% of the mass of the filling substance. After the slurry is adjusted, the slurry is evenly sprayed on the pretreated film precursor material in step (1), and the thickness of the sprayed slurry is 0.2 mm, placed in a vacuum dryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com