Preparation method of activated carbon fiber

A technology of activated carbon fiber and activated carbon fiber, applied in fiber treatment, plant fiber, fiber chemical characteristics, etc., can solve the problems of cumbersome preparation process, strict equipment requirements, equipment corrosion, etc., and achieve simplified process steps, developed voids, and strong adsorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation of activated carbon fiber, concrete steps are as follows:

[0032] Soak the cotton linters in 5% ammonium dihydrogen phosphate solution, take it out and dry it after 1 hour; then put the dried cotton linters into a tube furnace, and carry out carbonization activation under the protection of nitrogen, 425 ℃ carbonization for 60 minutes; then the temperature was raised to 900 ℃ at a rate of 8 ℃ / min, and activated by passing water vapor for 30 minutes; after the product was naturally cooled, it was taken out, put into a vacuum drying oven, and dried at 60 ℃ for 12 hours to obtain activated carbon fibers.

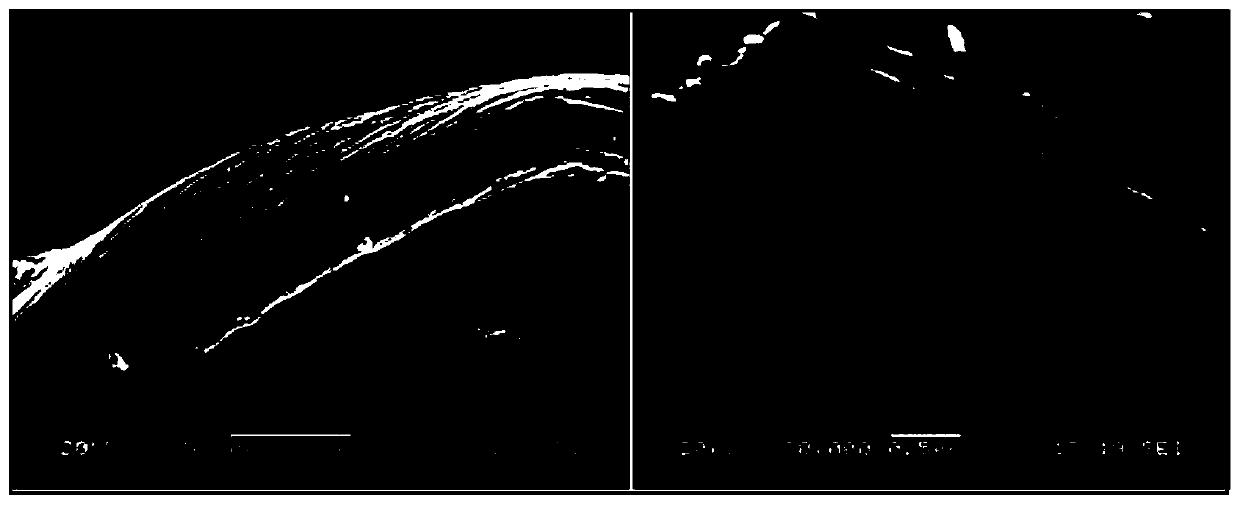

[0033] The electron microscope picture of the activated carbon fiber that the present embodiment gains is as figure 1 shown. It can be seen from the figure that the surface of the prepared activated carbon fibers has different degrees of unevenness, which shows that the activation is complete. The unevenness is formed by water vapor etching the amorphou...

Embodiment 2

[0043] The preparation of activated carbon fiber, concrete steps are as follows:

[0044] Soak the cotton linters in 5% ammonium dihydrogen phosphate solution, take it out and dry it after 1 hour; then put the dried cotton linters into a tube furnace, and carry out carbonization activation under the protection of nitrogen, 425 ℃ carbonization for 60 minutes; then the temperature was raised to 900 ℃ at a rate of 10 ℃ / min, and water vapor was introduced to activate for 40 minutes; after the product was naturally cooled, it was taken out, put into a vacuum drying oven, and dried at 60 ℃ for 12 hours to obtain activated carbon fibers.

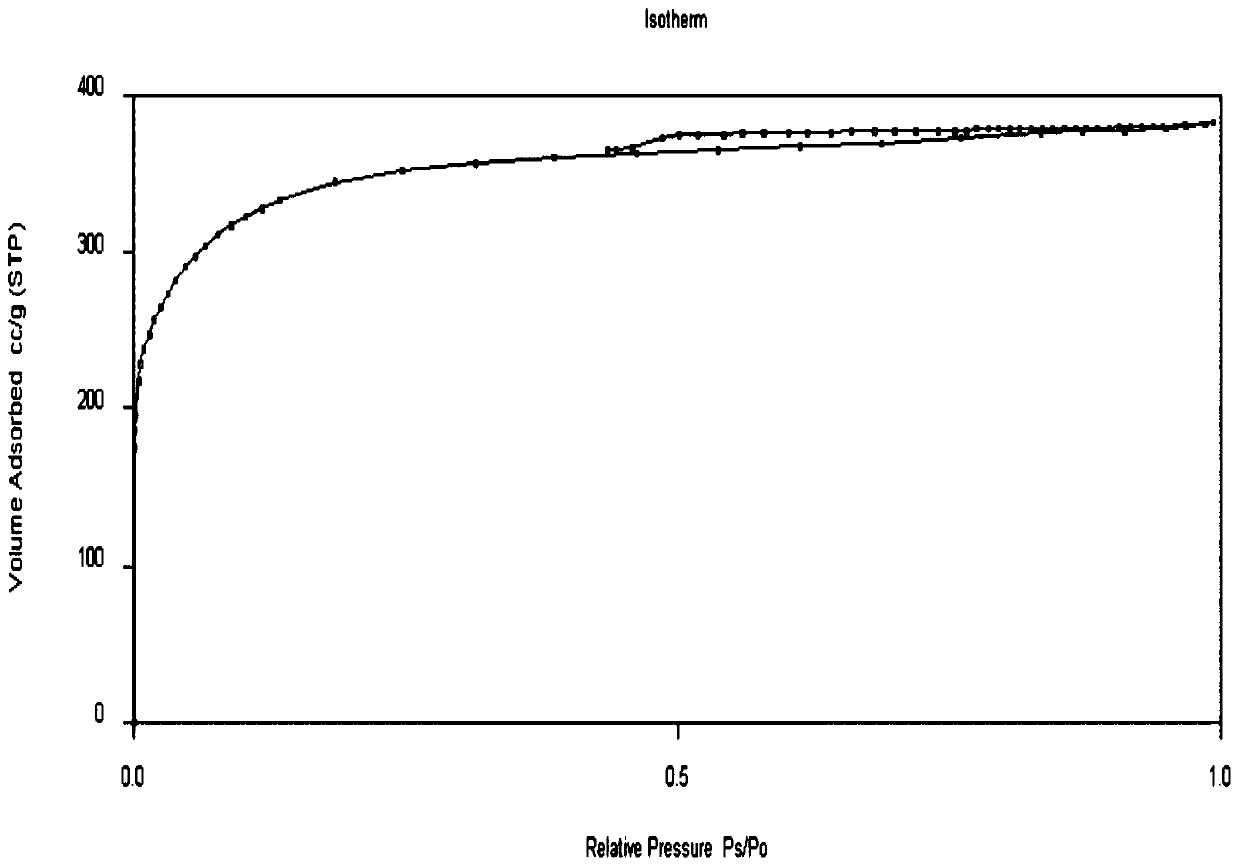

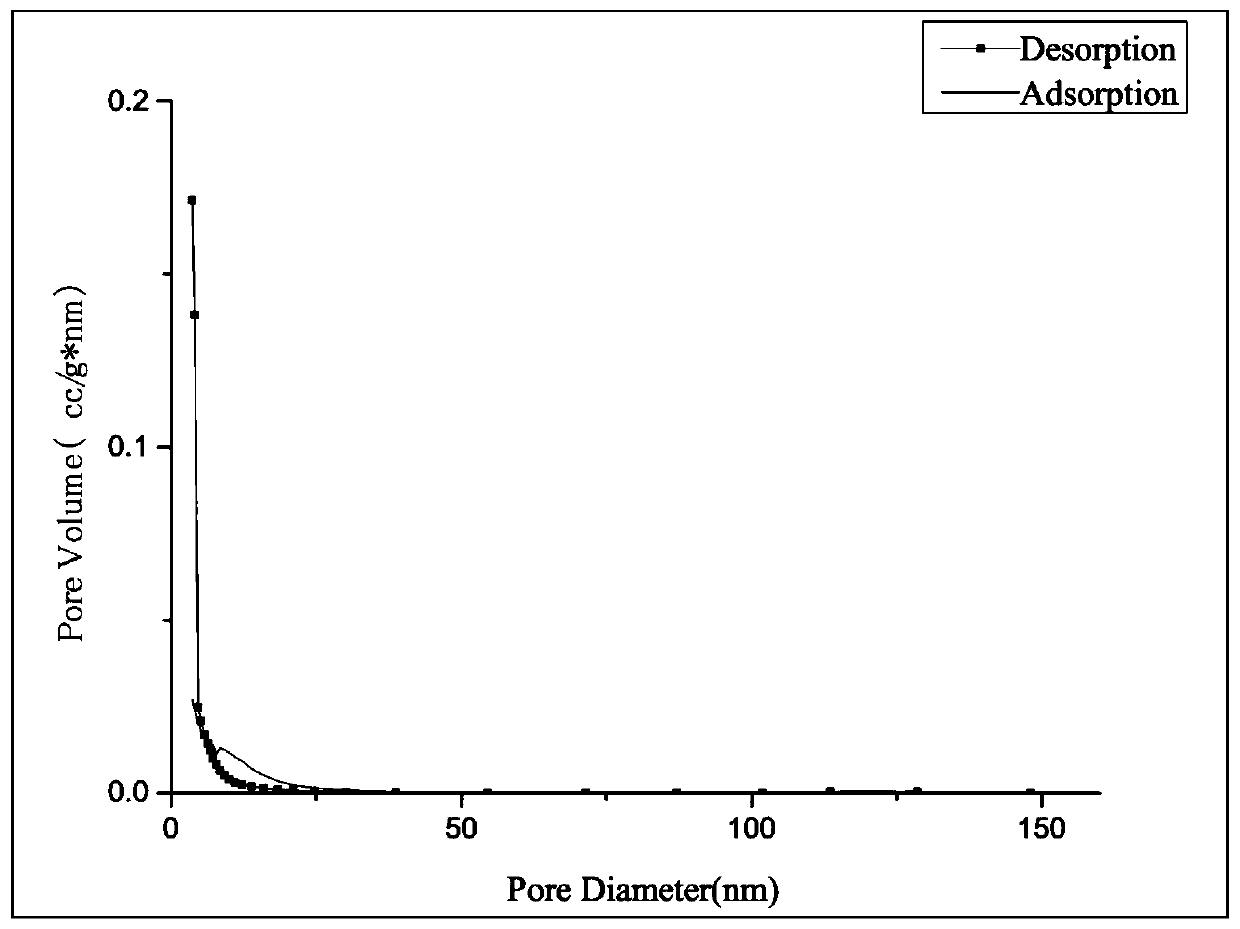

[0045] Adopt aperture specific area analyzer (SA 3100), calculate according to BET method, the specific surface area of the activated carbon fiber obtained in the present embodiment is 1512.05m 2 / g.

Embodiment 3

[0047] The preparation of activated carbon fiber, concrete steps are as follows:

[0048] Soak the cotton linters in 5% potassium dihydrogen phosphate solution, take it out and dry it after 1 hour; then put the dried cotton linters into a tube furnace, and carry out carbonization activation under the protection of nitrogen, 425 ℃ carbonization for 60 minutes; then raise the temperature to 900 ℃ at a rate of 10 ℃ / min, pass through water vapor to activate for 50 minutes; take out the product after natural cooling, put it in a vacuum drying oven, and dry it at 60 ℃ for 12 hours to obtain activated carbon fibers.

[0049] Adopt aperture specific area analyzer (SA 3100), calculate according to BET method, the specific surface area of the activated carbon fiber obtained in the present embodiment is 1524.09m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com