Preparation method of conductive carbon material with hierarchical porous structure, and pole plate for lead acid battery

A lead-acid battery and multi-level pore technology, applied in the field of materials science, can solve the problems of large differences in the properties of carbon materials, complex purity and preparation processes, and low carbon content in water loss, so as to increase the loading of active materials and ensure fast The effect of smooth transmission and improved cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

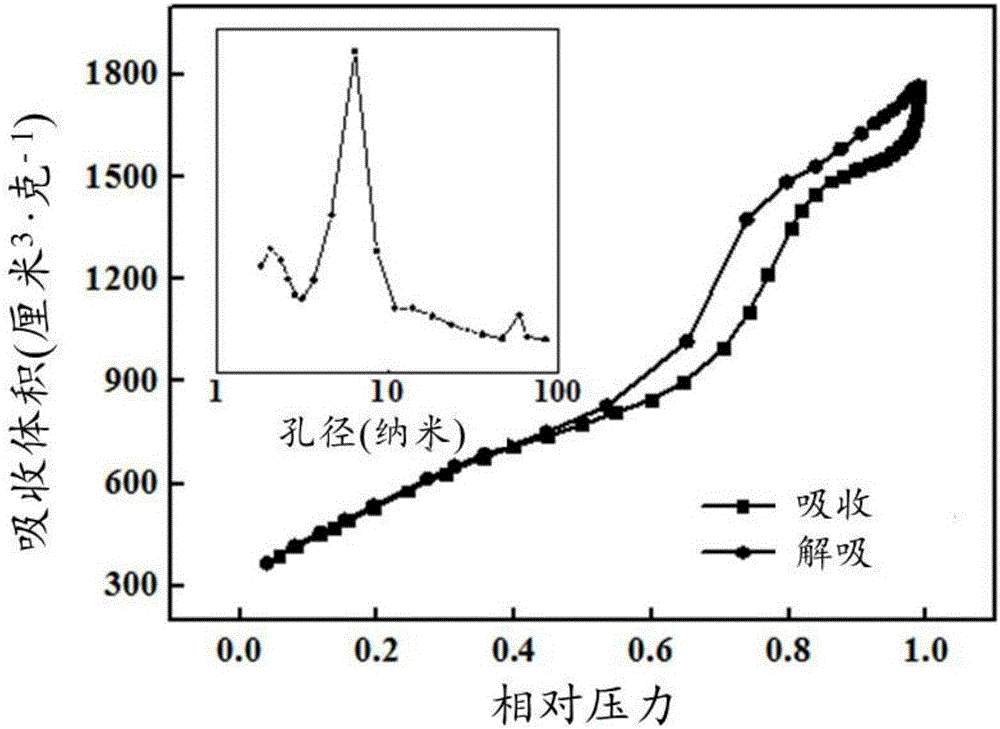

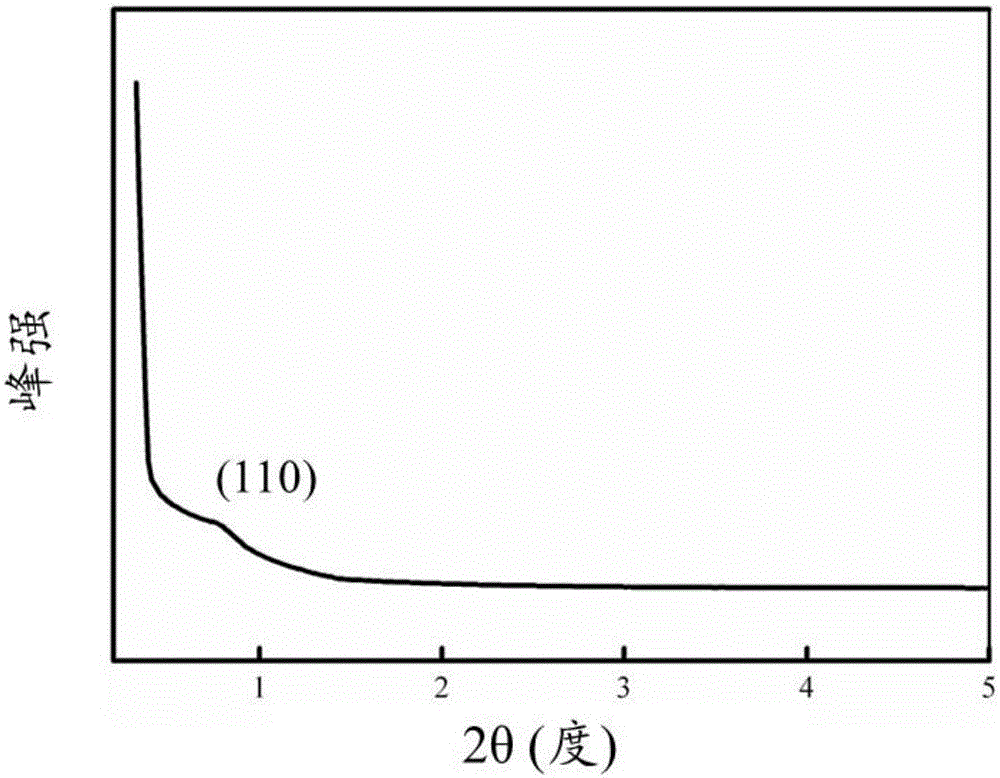

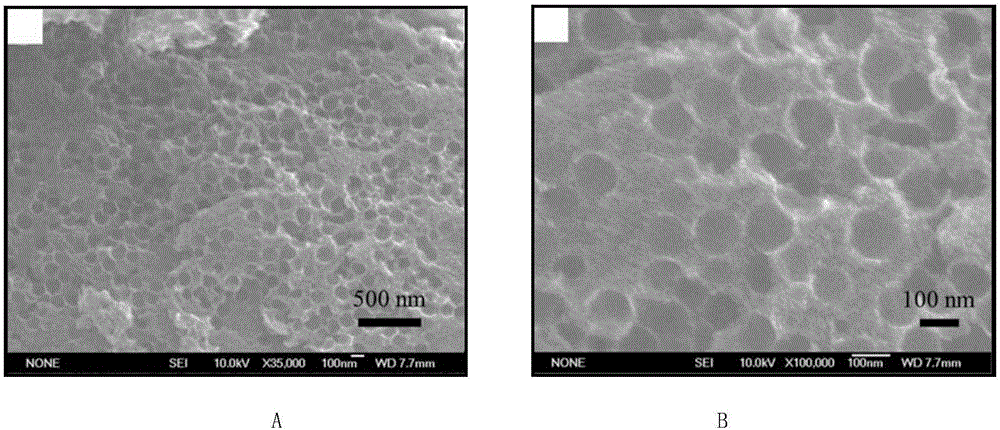

[0049] Embodiment 1: prepare the conductive carbon material of multilevel structure

[0050] The manufacturing method comprises the steps of:

[0051] 1) Synthesis of phenolic resin precursor

[0052] First dissolve 0.61g of phenol (phenol) in the flask in the temperature range of 40-42°C, add 0.13g of 20wt.% NaOH aqueous solution and stir for 10 minutes, then add 1.05g of formaldehyde dropwise and keep the temperature below 50 ℃, then raise the temperature to 70-75℃ and continue to stir for 1 hour, stop the heating and let the mixture cool down to room temperature naturally, use hydrochloric acid to adjust the pH value to about 7, and finally use a rotary evaporator to remove water at 50℃, and finally turn the light yellow The product was dissolved in 20 wt% ethanol solution.

[0053] 2) Synthesis of Hierarchical Porous Carbon / Silicon Oxide Composite Materials

[0054] The carbon / silicon oxide composite material with a hierarchical porous structure was prepared by co-assem...

Embodiment 2

[0066] Embodiment 2: Preparation and electrochemical characteristic characterization process of hierarchical porous carbon electrode

[0067]The obtained highly conductive hierarchical porous material is configured into an electrode slurry or directly combined with a conductive material to form an electrode; for example, the carbon material is uniformly mixed with a conductive agent, a binder, and a dispersing solvent in a certain proportion to obtain an electrode slurry , coated on the current collector, and dried to form an electrode. The obtained electrode is combined with the positive electrode, and a diaphragm and an electrolyte are added to form an initial battery; after the battery is activated, a lead-carbon electrode with excellent performance is obtained. For example, the obtained electrode is paired with a lead oxide electrode, separated by a separator, and an acidic electrolyte is added to form a single battery, and electrochemical tests are performed.

[0068] Th...

Embodiment 3

[0069] Embodiment 3: the preparation method of lead-carbon battery negative pole plate

[0070] The hierarchically porous structure conductive carbon material obtained in Example 1 was added to the negative electrode and the paste as an additive in different proportions, and the plate was prepared according to the formula of the negative electrode of the lead-acid battery of the electric power-assisted bicycle (attached table 2). The process of curing and formation is shown in Table 3, and the specific parameters of curing and formation are shown in Table 4. Finally, after the formed plate is dried, it is assembled, filled with acid and sealed in the way of traditional lead-acid battery, and then left for 24 hours for testing.

[0071] Table 2 Preparation formula of lead-carbon battery negative electrode

[0072]

[0073] Table 3 Lead-carbon battery curing process parameters

[0074] temperature humidity time 1 48℃ >98% 48h 2 70℃ <2%

5h ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com