Porous metal aeration electrode capable of producing hydrogen peroxide based on electrocatalysis, and preparation method thereof

A porous metal, electrocatalytic technology, used in chemical instruments and methods, water/sewage treatment, sterilization/microdynamic water/sewage treatment, etc., can solve the problem of short service life of acetylene black/PTFE electrodes and insufficient active components Utilization, easy pulverization and low surface area, etc., to achieve the effect of high utilization rate of active substances, poor mass transfer performance improvement, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] An aspect of the embodiments of the present invention provides a porous metal aeration electrode based on electrocatalytic hydrogen peroxide production, including: a porous metal substrate and an electrocatalytic active layer supported on the porous metal substrate.

[0038] The porous metal substrate is a porous metal material formed by pressing and sintering metal powder materials; the electrocatalytic active layer is a carbon material with a micro-nano structure.

[0039] Preferably, the metal powder material is titanium, stainless steel, copper and nickel.

[0040] Preferably, the carbon material with micro-nano structure is acetylene black, carbon nanotubes, graphene, graphene oxide, and reduced graphene oxide.

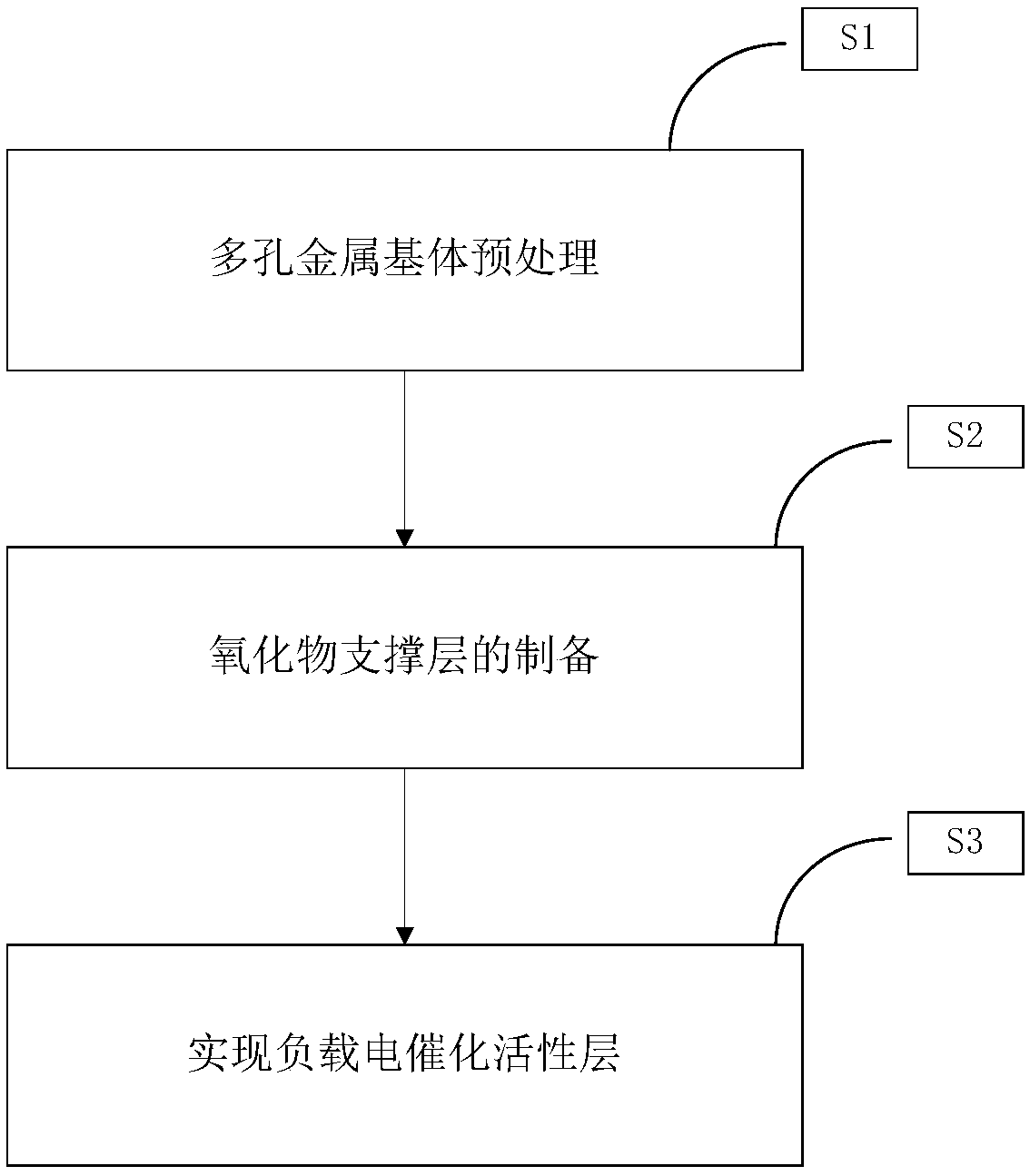

[0041] Preferably, a support layer is further provided between the porous metal base and the electrocatalytic active layer, and the support layer is a nano-morphological aggregate of metal oxides grown on the porous metal base in situ. Schematically, the ...

Embodiment 2

[0055] A tubular porous stainless steel aeration electrode loaded with reduced graphene oxide and a preparation method thereof.

[0056] One aspect of this embodiment provides that this embodiment provides a tubular porous stainless steel aeration electrode loaded with reduced graphene oxide, including: a tubular porous stainless steel with a pore diameter of 50 μm is a porous metal substrate, and graphene oxide in a reduced state is an electrocatalytic active layer. No supporting layer is provided between the porous metal substrate and the electrocatalytically active layer.

[0057] Another aspect of this embodiment provides a method for preparing a tubular porous stainless steel aeration electrode loaded with reduced graphene oxide, the method is:

[0058] 1) Pretreatment of the porous metal substrate: Soak the porous stainless steel substrate in acetone solution and ultrasonically clean it for 15 minutes, then wash it with absolute ethanol, put it in a vacuum drying oven fo...

Embodiment 3

[0061] This example provides a tubular porous titanium aeration electrode loaded with reduced graphene oxide and its preparation method

[0062] One aspect of this embodiment provides a tubular porous titanium aeration electrode loaded with reduced graphene oxide. The active layer is provided with TiO 2 Nanoflower support layer.

[0063] Another aspect of this embodiment provides a method for preparing a tubular porous titanium aeration electrode loaded with reduced graphene oxide, the method comprising:

[0064] Step 1: Pretreatment of the porous metal substrate: Soak the porous metal titanium substrate in acetone solution, ultrasonically clean it for 15 minutes, then wash it with absolute ethanol, dry it in vacuum at 90°C, and cool it to room temperature for use;

[0065] Step 2: Construction of micro-nano structure TiO by hydrothermal method 2 Nanoflower support layer: 1) soak the porous metal titanium substrate in a mixed acid solution containing HF acid and HCl acid fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com