Lead-acid storage battery and lead-acid storage battery pack

A lead-acid battery and battery pack technology, applied in the battery field, can solve the problems of battery thermal runaway, complex process, poor compatibility of positive and negative electrode preparation processes, etc., and achieve the effect of improving accuracy and expanding management scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

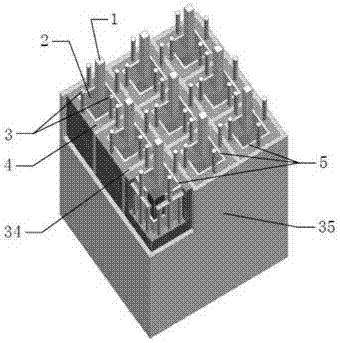

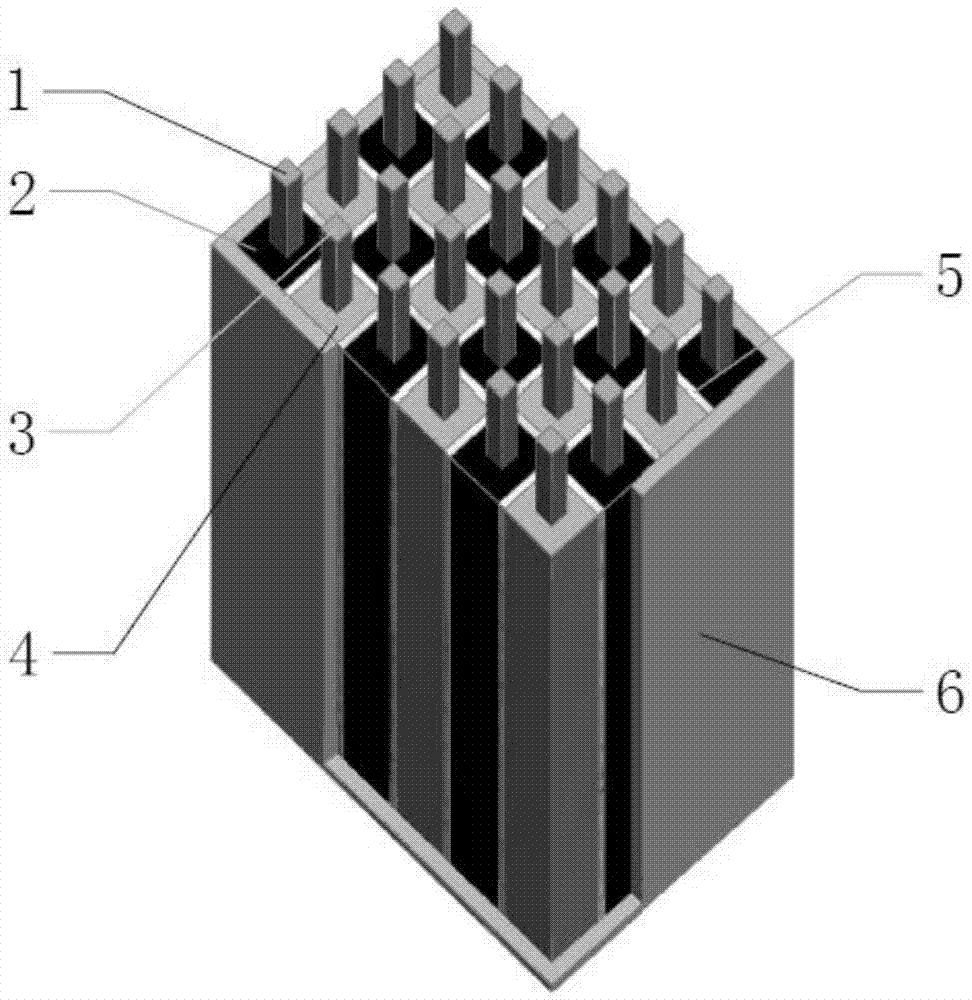

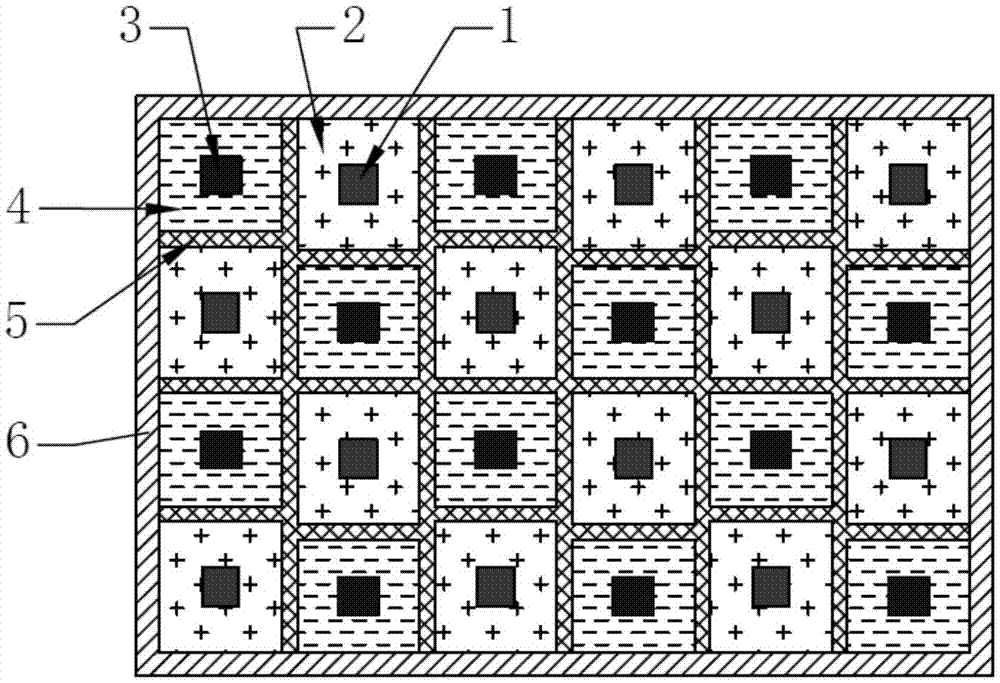

[0100] The lead-acid accumulator of present embodiment, its three-dimensional anatomical structure such as figure 1 As shown, the shape of the radial cross-section of the electrode column and its array are as follows figure 2 As shown, except for the edge of the battery, each positive electrode active material 2 columns is adjacent to 4 negative electrode active material 4 columns, and each negative electrode active material 4 columns is adjacent to 4 positive electrode active material 2 columns. The physical shape of 2 columns of positive active material and 4 columns of negative active material is a quadrangular prism with a height of 68mm, and the radial cross-sections of the columns are respectively 4mm×4.3mm and 4mm×3.7mm rectangular; The mass of the active material 2 is 4.6 g, and the mass of the negative electrode active material 4 is 4 g. The physical shape of the positive electrode current collector 1 and the negative electrode current collector 3 is also a quadran...

Embodiment 2

[0106] In the lead-acid storage battery of this embodiment, the radial cross-sectional shape and array of the electrode columns are as follows: Figure 5 shown. Among them, the physical shape of the positive electrode active material 2 is a positive cylinder with a height of 165 mm, a circular cross-sectional shape and a diameter of 5 mm, and the mass of a single positive electrode active material 2 is 11.7 g. The outer surface of the cylinder of the positive electrode active material 2 is in contact with the cylindrical separator 5 with a thickness of 1 mm, and the outer surface of the separator 5 is in contact with the side wall 7 of the electrode chamber. The physical shape of the electrode chamber has two shapes: cylindrical and straight curved wall hexagonal cylindrical shape. The cylindrical electrode chamber contains the positive electrode and the separator 5, and the straight curved wall hexagonal cylindrical electrode chamber contains the negative electrode. The thic...

Embodiment 3

[0114] The lead-acid storage battery of this embodiment is a surrounding sleeve-type lead-acid storage battery, and its electrode column radial cross-sectional shape and array are as follows: Figure 7 shown. Two columns of positive active material are adjacent to two columns of negative active material on both sides, and at the same time, two columns of negative active material are adjacent to two columns of positive active material. The physical shapes of the 2 columns of positive electrode active material and the 4 columns of negative electrode active material are cylindrical columns, and the radial cross-sectional shapes are circular rings with a height of 280 mm. The positive and negative cylindrical columns are nested alternately to form a ring-type electrode structure. A separator 5 is arranged between the positive electrode and the negative electrode, the thickness of each layer of separator is 1 mm, and the material is ultrafine glass fiber. The positive and negativ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com