Triphenylthiol additive-containing lithium-sulfur battery electrolyte and lithium-sulfur battery

A lithium-sulfur battery and benzene trithiol technology are applied in the field of lithium-sulfur battery electrolyte and lithium-sulfur battery, and can solve the problem that lithium negative electrode and sulfur positive electrode cannot be solved at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]A lithium-sulfur battery electrolyte (BTT electrolyte) containing a benzenetrithiol additive is provided, including ether solvents, lithium salts and additives; wherein the ether solvents are a mixed solution of DOL and DME at a volume ratio of 1:1 , the lithium salts LiTFSI and LiNO 3 , the concentration of LiTFSI in the electrolyte is 1mol / L, LiNO 3 The concentration in the electrolyte is 0.15 mol / L, and the additive is 1,3,5-benzenetrithiol (BTT), and the concentration in the electrolyte is 0.15 mol / L.

[0040] Configuration matrix lithium sulfur electrolyte, described matrix lithium sulfur electrolyte is to contain 1mol / L LiTFSI and 0.15mol / LLiNO 3 A solution of DOL and DME (volume ratio of DOL and DME is 1:1). The matrix lithium-sulfur electrolyte was used as a comparative example to set up a control group.

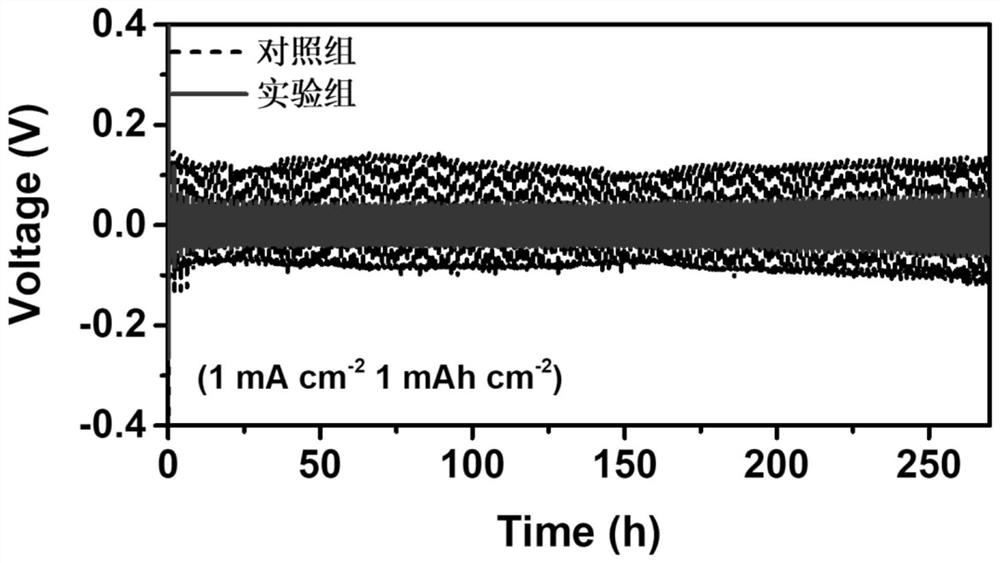

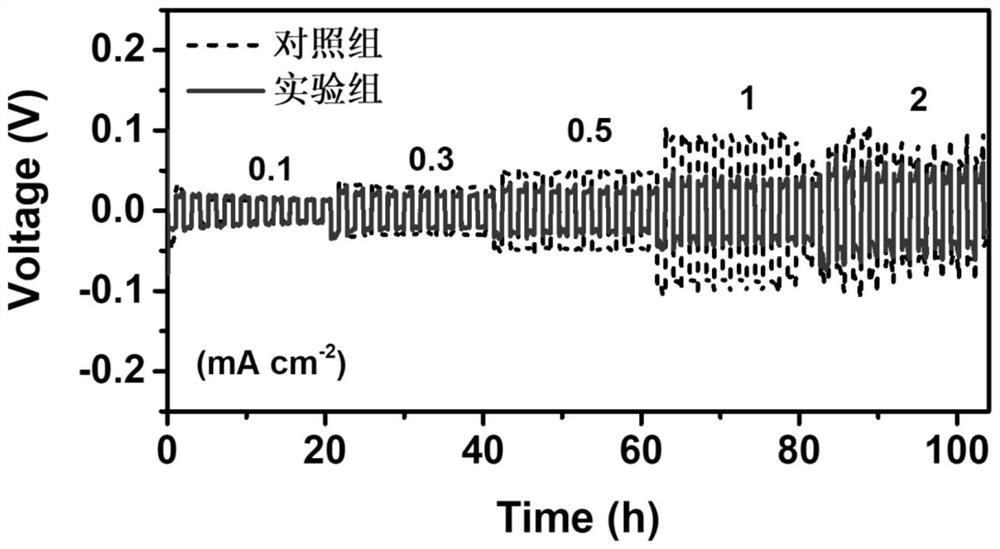

[0041] The lithium-sulfur battery electrolyte (BTT electrolyte) or matrix lithium-sulfur electrolyte containing benzenetrithiol additive obtained in this ex...

Embodiment 2

[0047] Assembling lithium-sulfur CR2032 button cell, including the carbon nanotube positive electrode, diaphragm, lithium metal negative electrode and electrolyte of loading sulfur element, wherein electrolyte is the lithium-sulfur battery electrolyte or matrix electrolysis containing benzenetrithiol additive in embodiment 1 liquid. When the electrolyte is the lithium-sulfur battery electrolyte containing the benzenetrithiol additive in Example 1, it is set as the experimental group, and when the electrolyte is the matrix electrolyte, it is set as the control group.

[0048] In the carbon nanotube positive electrode loaded with sulfur element, the sulfur loading is 1 mg cm -2 , The carbon nanotube paper diameter is 11mm. It is prepared by dissolving sulfur solid powder in carbon disulfide solvent, adding dropwise on carbon nanotube paper, drying in a blast oven at 60-65°C for 12-13 hours to volatilize the solvent.

[0049] The diaphragm is Celgard-2400 with a diameter of 19m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com