A polyimide separator lithium-sulfur battery and a preparation method thereof

A polyimide, lithium-sulfur battery technology, applied in the field of chemical power sources, can solve problems such as poor safety, explosion, battery short circuit, etc., and achieve the effects of improving the utilization rate of active materials, wide application prospects, and improving safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

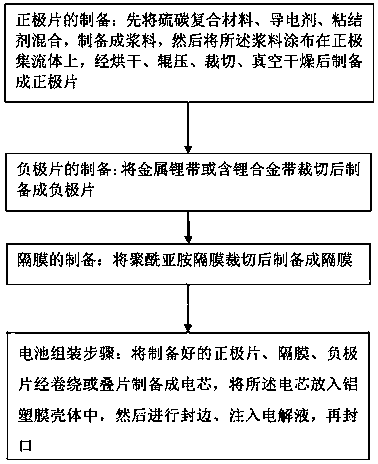

[0015] as attached figure 1 Shown, the preparation method of polyimide diaphragm lithium-sulfur battery comprises the following steps:

[0016] (1) Preparation of the positive electrode sheet: first mix the sulfur-carbon composite material, conductive agent, and binder to prepare a slurry, then coat the slurry on the positive electrode current collector, and dry, roll, and cut , Prepared into a positive electrode sheet after vacuum drying;

[0017] (2) Preparation of negative electrode sheet: cutting metal lithium strip or lithium-containing alloy strip to prepare negative electrode sheet;

[0018] (3) Preparation of the diaphragm: the polyimide diaphragm is cut and prepared into a diaphragm;

[0019] (4) Battery assembly: Firstly, the prepared positive electrode sheet, diaphragm, and negative electrode sheet are wound or stacked to form a battery cell, and the battery cell is placed in an aluminum-plastic film casing, and then the edge is sealed and the electrolyte is injec...

Embodiment 1

[0032] Preparation of the positive electrode sheet: mix the sulfur / ketjen black composite material with a sulfur content of 60%, acetylene black, sodium carboxymethyl cellulose, and styrene-butadiene latex in a mass ratio of 80%: 10%: 4%: 6%. Deionized water was used as a solvent to prepare a slurry, and then coated on an aluminum foil with a thickness of 18 μm, pre-baked in an oven at 60 ° C, and then rolled, cut into pieces, and dried in a vacuum oven at 60 ° C for 24 hours to prepare a positive electrode piece.

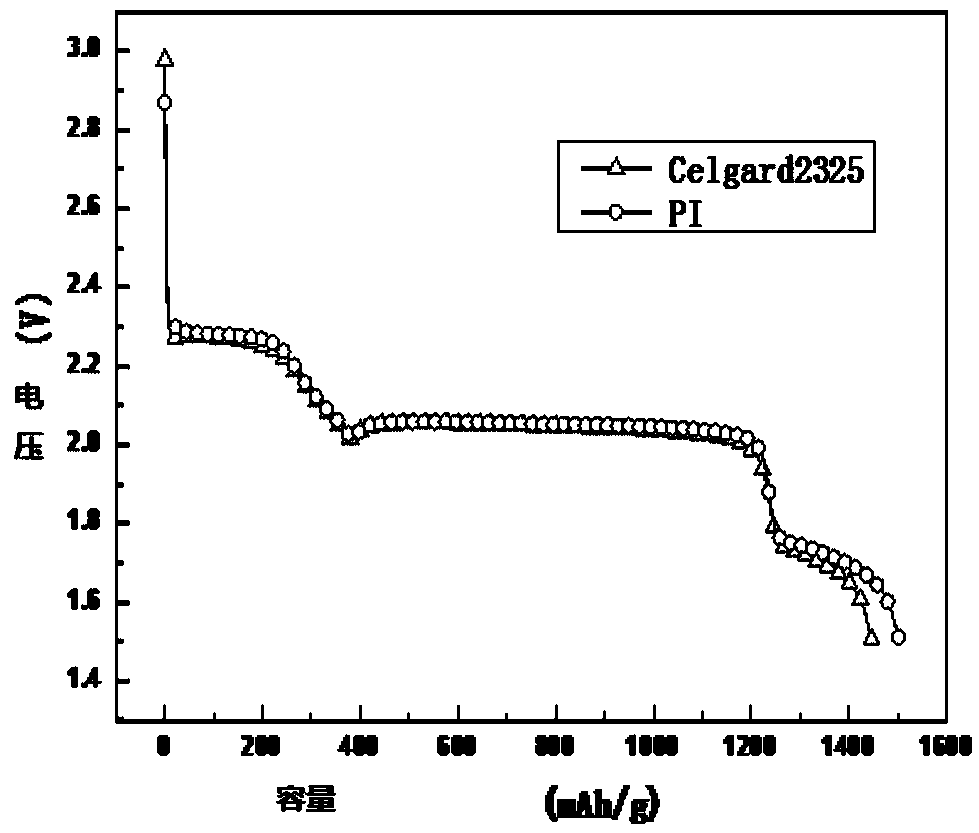

[0033] The negative plate is made of metal lithium strip, and the capacity ratio of positive and negative active materials is 1:1.5; the diaphragm is made of polyimide diaphragm with a thickness of 25 μm. Wind the positive electrode sheet, separator, and negative electrode sheet to prepare the battery core, then put it into the formed aluminum-plastic film for edge sealing, and inject 1.0mol / L LiN(CF 3 SO 2 ) 2 +DOL / DME(v / v=1:1)+0.1mol / L LiNO 3 The electrolyte ...

Embodiment 2

[0037] Preparation of the positive electrode sheet: mix the sulfur / ketjen black composite material with a sulfur content of 70%, acetylene black, and polyvinylidene fluoride at a mass ratio of 85%:5%:10%, and use N-methylpyrrolidone as a solvent to prepare The slurry was then coated on an aluminum foil with a thickness of 18 μm, pre-baked in an oven at 60° C., rolled, cut into pieces, and dried in a vacuum oven at 60° C. for 24 hours to prepare a positive electrode sheet.

[0038]The negative plate is made of metal lithium strip, and the capacity ratio of positive and negative active materials is 1:1.5; the diaphragm is made of polyimide diaphragm with a thickness of 25 μm. Wind the positive electrode sheet, separator, and negative electrode sheet to prepare the battery core, then put it into the formed aluminum-plastic film for edge sealing, and inject 1.0mol / L LiN(CF 3 SO 2 ) 2 +DOL / DME(v / v=1:2)+0.2mol / L LiNO 3 The electrolyte solution is then sealed to prepare a polyimid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com