Preparation method of modified short fiber for lead-acid battery and negative plate containing modified short fiber

A lead-acid battery and negative plate technology, applied in battery electrodes, electrode carriers/current collectors, circuits, etc., can solve the problems of poor cycle stability and low specific energy of lead-acid batteries, and achieve good charging and discharging performance, low investment, The effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

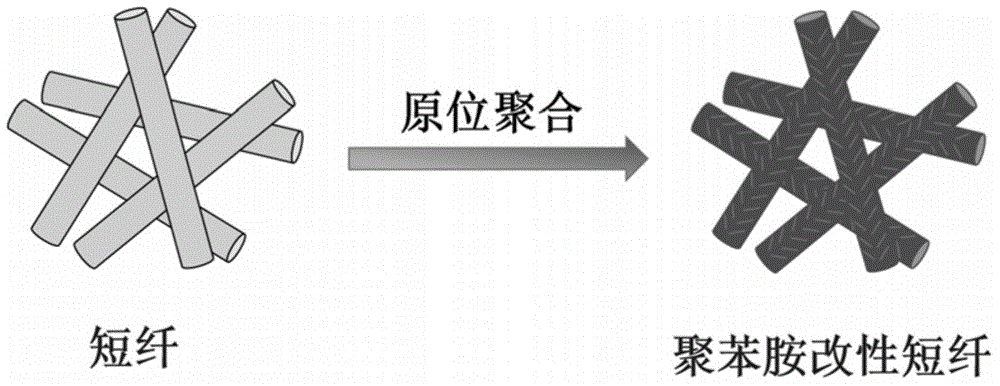

[0030] The preparation method of modified short fiber for lead-acid battery of the present invention comprises the steps:

[0031] 1) Disperse the short fibers for industrial use in a protonic acid solution with a concentration of 1 to 5 mol / L, and stir them ultrasonically to make the short fibers evenly dispersed;

[0032] 2) Add a certain amount of polymer monomer to the above mixture, stir in an ice-water bath for 1-10 hours, the mass ratio of polymer monomer to short fiber is 10:1-10; Dissolve ammonium persulfate (APS) in a protonic acid solution with a concentration of 1 to 5 mol / L, and add it dropwise by dropwise addition. After the dropwise addition, continue to stir, and stir at 0°C for 12 to 36 hours during the polymerization process. ;

[0033] 3) After the reaction is finished, carry out vacuum filtration, rinse repeatedly with distilled water, and dry at 60° C. to obtain modified short fibers.

[0034] Wherein the protonic acid in steps 1) and 2) is one of sulfur...

Embodiment 1

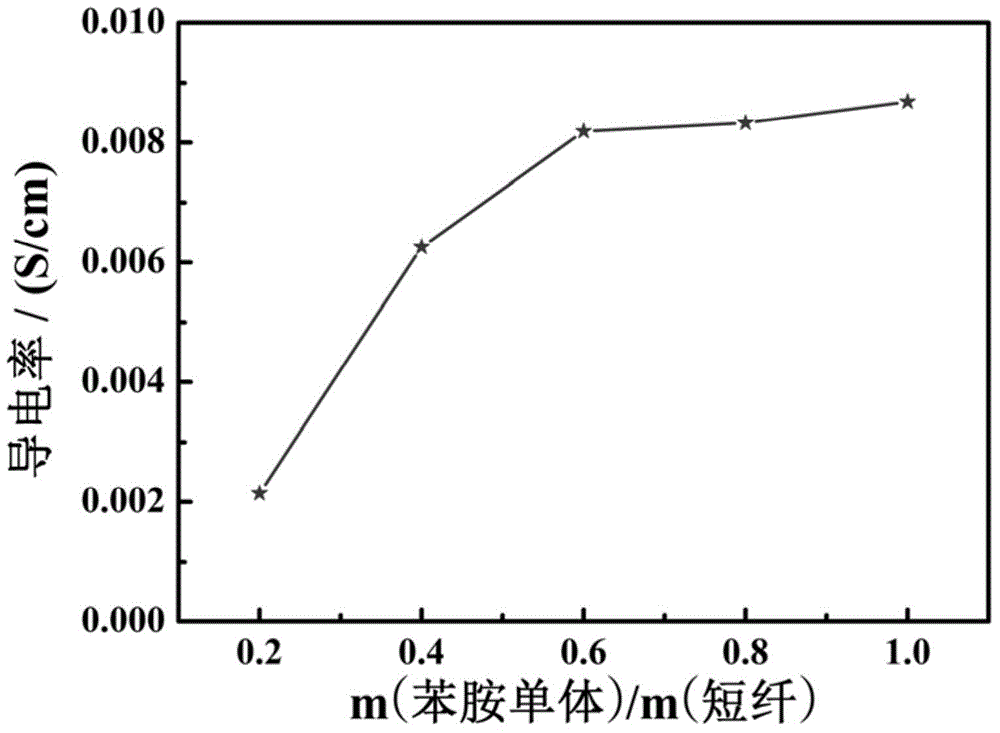

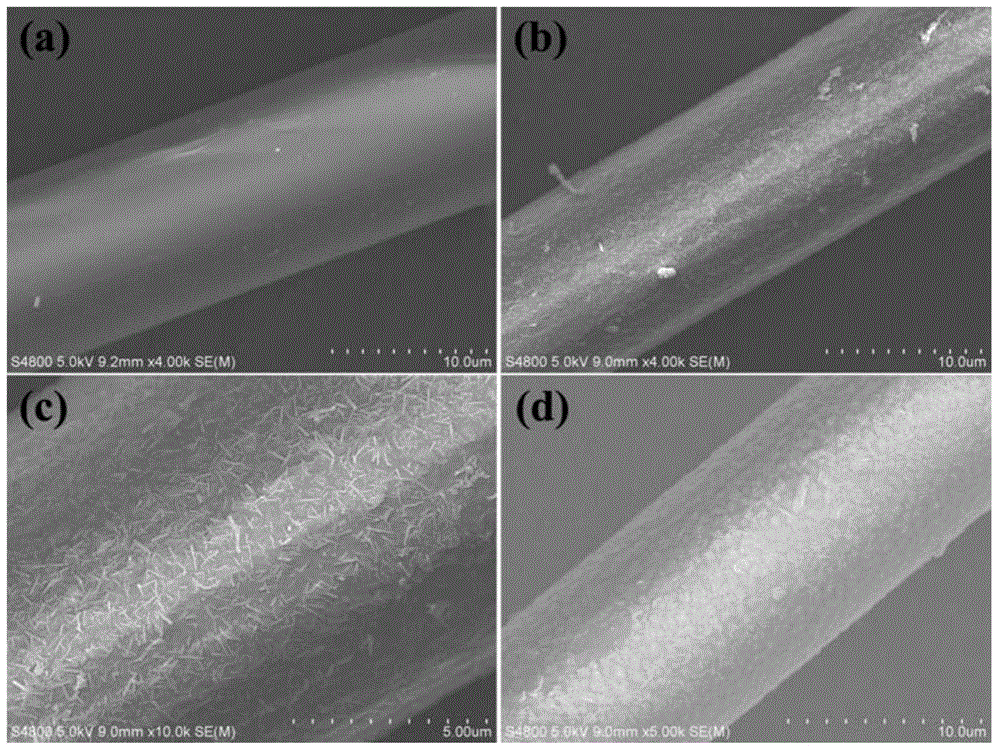

[0042] The preparation method of the modified short fiber of this embodiment is: disperse the short fiber for industrial use in the sulfuric acid solution of 1mol / L, stir ultrasonically to make the short fiber disperse evenly; mix a certain amount of aniline monomer Add it to the above mixture, stir in an ice-water bath for 2 hours, the mass ratio of aniline monomer to short fiber is 10:2; dissolve ammonium persulfate (APS) which is equimolar to aniline monomer in 1mol / L sulfuric acid solution , in the way of dropwise addition, after the dropwise addition, continue to stir, and stir at 0°C for 24h during the polymerization process; After the reaction, perform vacuum filtration, rinse repeatedly with distilled water, and dry at 60°C to obtain Modified staple fiber.

Embodiment 2

[0044] The preparation method of the modified short fiber of this embodiment is: disperse the short fiber for industrial use in the sulfuric acid solution of 2mol / L, stir ultrasonically to make the short fiber disperse evenly; mix a certain amount of aniline monomer Add it to the above mixture, stir in an ice-water bath for 5 hours, the mass ratio of aniline monomer to short fiber is 10:4; dissolve ammonium persulfate (APS) which is equimolar to aniline monomer in 2mol / L sulfuric acid solution , in the way of dropwise addition, after the dropwise addition, continue to stir, and the polymerization process is stirred at 0°C for 36h; After the reaction is completed, perform vacuum filtration, rinse repeatedly with distilled water, and dry at 60°C to obtain Modified staple fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com