Chargeable zinc electrode additive, and its preparing method and use

An additive, zinc electrode technology, used in electrode manufacturing, battery electrodes, active material electrodes, etc., can solve the problem of reducing the utilization rate and conductivity of zinc anode active materials, improving cycle life efficiency is not large, and zinc-nickel battery cycle life It can improve the comprehensive electrochemical performance, improve the cycle life, improve the utilization rate and discharge capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

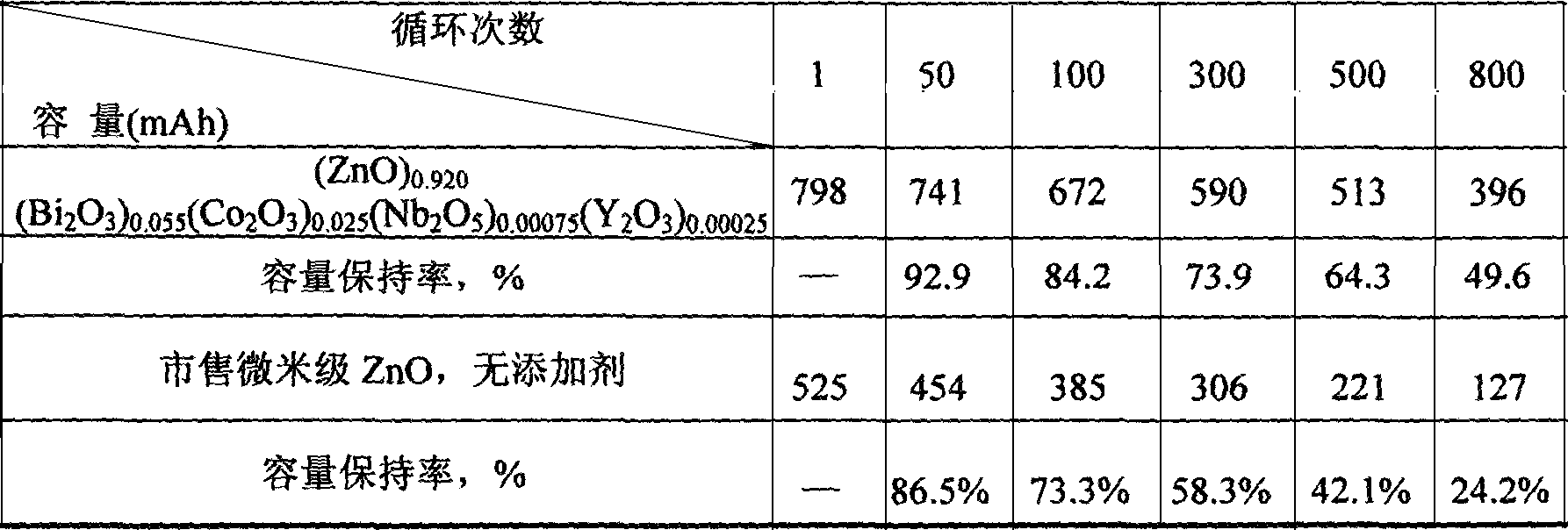

Embodiment 1

[0021] A kind of additive of rechargeable zinc electrode, its chemical composition is: the Bi of 92 weight parts ZnO, 5.5 weight parts 2 o 3 , 2.5 parts by weight of Co 2 o 3 , 0.075 parts by weight of Nb 2 o 5 , 0.025 parts by weight of Y 2 o 3 , and its particle size distribution is 0.1-1.0 μm.

[0022] The preparation method of the additive of the aforementioned rechargeable zinc electrode is: ZnO powder, Co 2 o 3 Powder, Bi 2 o 3 Powder and Nb 2 o 5 The powder is mixed according to the stoichiometric ratio, then put into the ball mill tank, and distilled water and polyacrylamide dispersant are added into the ball mill tank, the powder is wet milled in the ball mill tank for 60 hours, dried and then calcined at 1000°C for 2 hour, after cooling, sieve to get the intermediate raw material;

[0023] Dissolving tetrabutyl titanate in a mixed solution of glacial acetic acid, glycerol and ethanol, heating and stirring to obtain a uniform tetrabutyl titanate solution;...

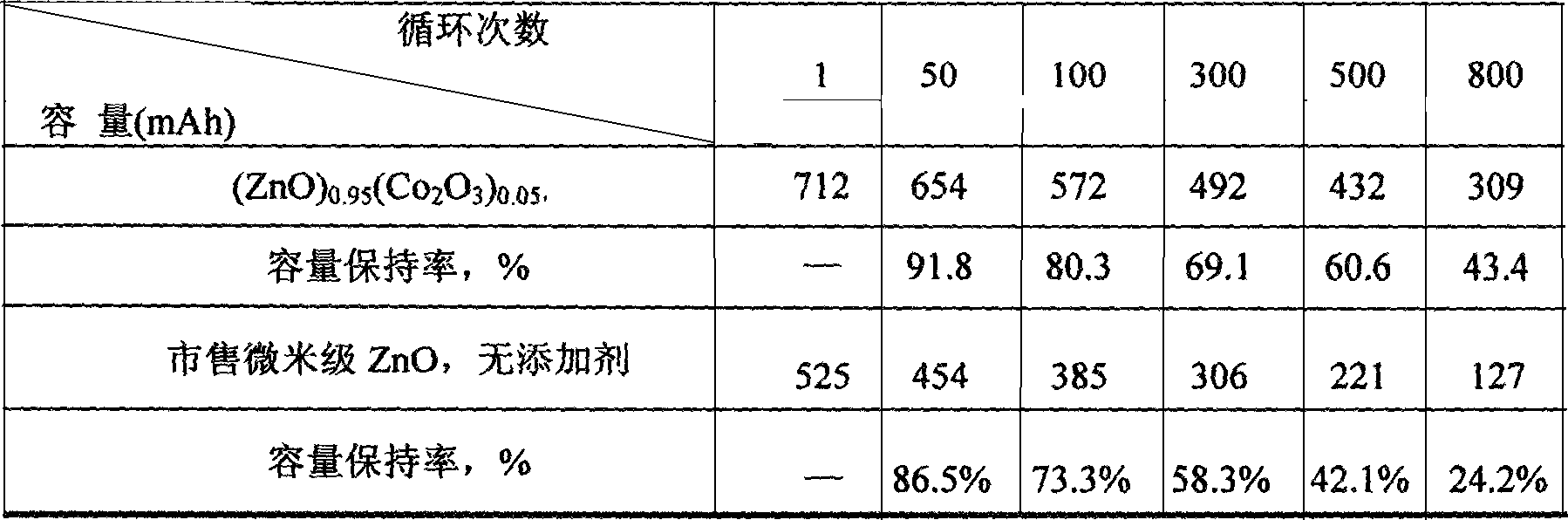

Embodiment 2

[0030] A kind of additive of rechargeable zinc electrode, its chemical composition is: the Co of 95 weight parts ZnO, 5 weight parts 2 o 3 , and its particle size distribution is 0.1-1.0 μm.

[0031] The method for making the additives of the foregoing rechargeable zinc electrodes is: ZnO powder, Co 2 o 3 The powder is mixed according to the stoichiometric ratio, then put into the ball mill tank, and distilled water and polyacrylamine dispersant are added into the ball mill tank, the powder is wet milled in the ball mill tank for 30 hours, dried and then calcined at 700 ° C for 2 Hours, cooled and sieved to obtain additives for rechargeable zinc electrodes.

[0032] Add the additive powder of the prepared rechargeable zinc electrode with a particle size of 0.1 to 1.0 μm into zinc oxide (the zinc oxide contains about 20% metal zinc zinc powder), and the weight ratio of the additive to the zinc oxide is 1:9, Then mix it in a ball mill for 1 hour, take it out and add an appro...

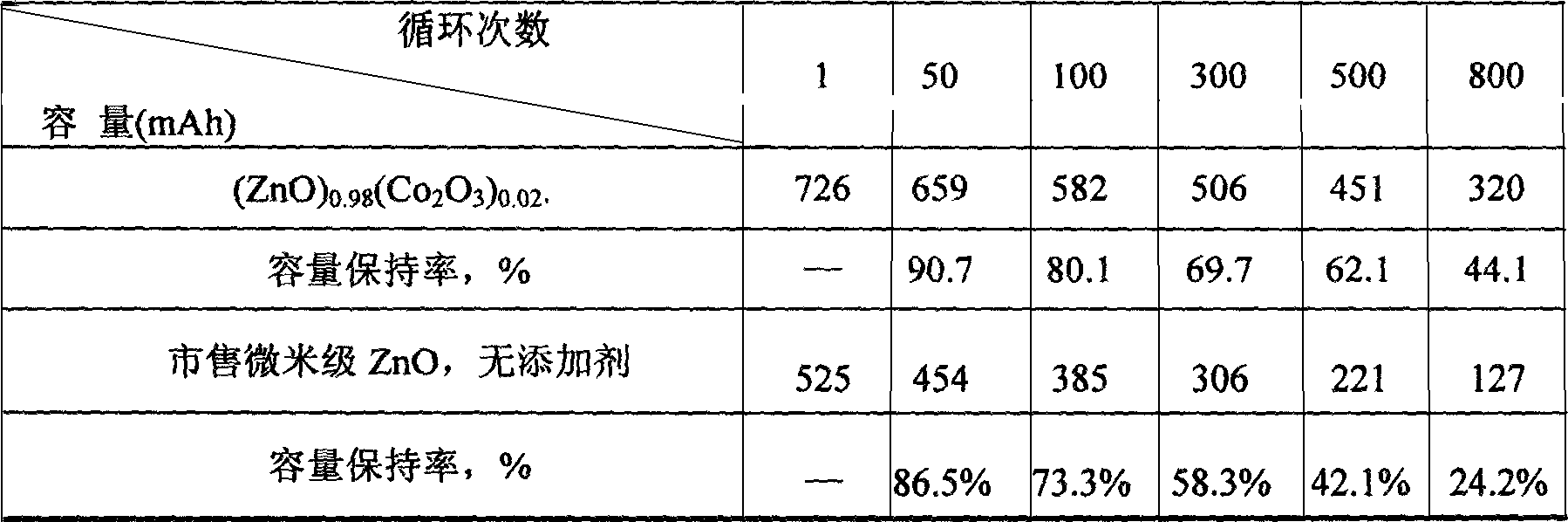

Embodiment 3

[0036] A kind of additive of rechargeable zinc electrode, its chemical composition is: the Co of 98 weight parts ZnO, 2 weight parts 2 o 3 , and its particle size distribution is 0.1-1.0 μm.

[0037] The preparation method of the additive of the aforementioned rechargeable zinc electrode is: ZnO powder, Co 2 o 3 The powder is mixed according to the stoichiometric ratio, then put into the ball mill tank, and distilled water and polyacrylamine dispersant are added into the ball mill tank, the powder is wet milled in the ball mill tank for 50 hours, dried and then calcined at 1000°C for 1.5 Hours, cooled and sieved to obtain additives for rechargeable zinc electrodes.

[0038] Add the additive powder of the prepared rechargeable zinc electrode with a particle size of 0.1 to 1.0 μm into zinc oxide (the zinc oxide contains about 20% metal zinc zinc powder), and the weight ratio of the additive to the zinc oxide is 1:9, Then mix it in a ball mill for 1 hour, take it out and add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com