Cathode material for alkaline secondary zinc electrode and its preparing method

A negative electrode material, secondary zinc technology, applied in the direction of alkaline battery electrodes, electrode manufacturing, battery electrodes, etc., can solve the problems of low charge acceptance, short cycle life, unstable capacity, etc., to reduce and prevent zinc dendrites, The effect of improving cycle life, improving utilization rate and discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

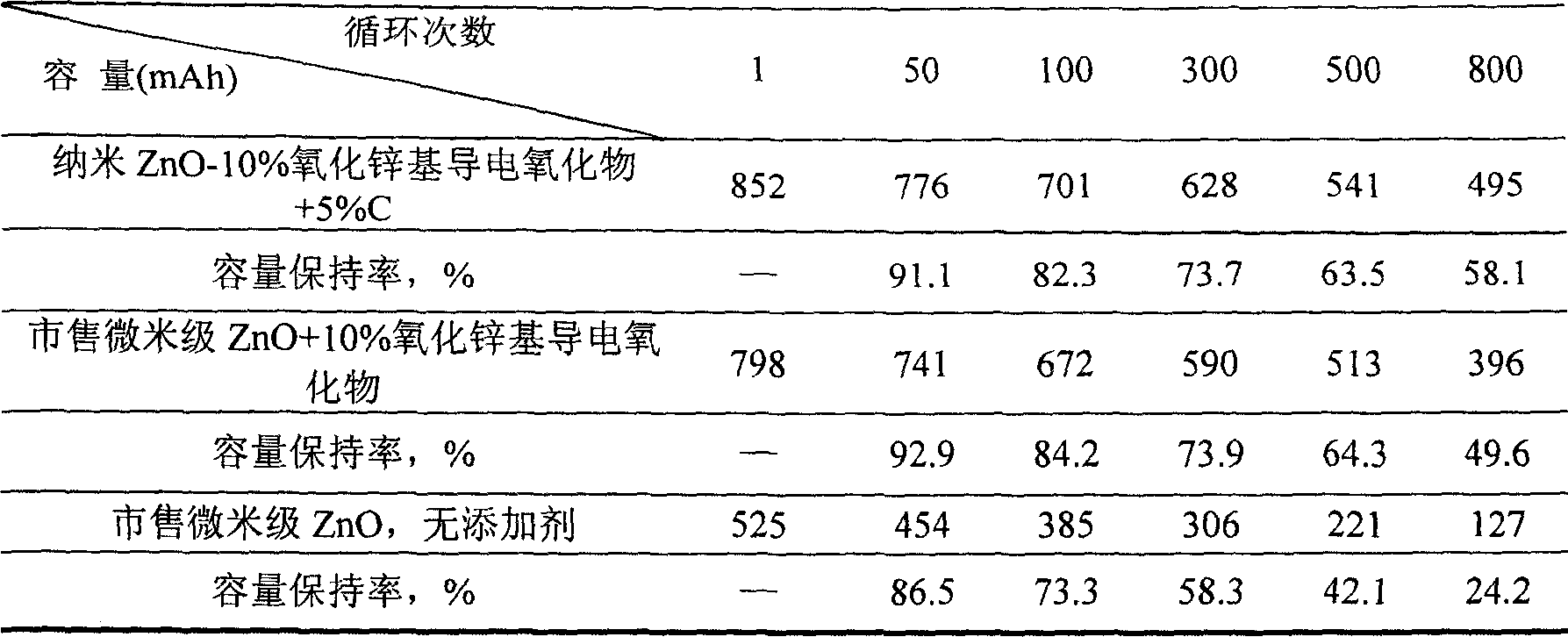

Embodiment 1

[0018] A negative electrode material for an alkaline secondary zinc electrode, which uses a zinc oxide-based conductive oxide as the inner core, and the inner core is uniformly coated with nanometer zinc oxide particles, and the chemical composition of the zinc oxide-based conductive oxide is: 92 Parts by weight of ZnO, 5.5 parts by weight of Bi 2 o 3 , 2.5 parts by weight of Co 2 o 3 , 0.075 parts by weight of Nb 2 o 5 , 0.025 parts by weight Y 2 o 3 .

[0019] Zinc nitrate is used as raw material, ammonia water and urea are used as precipitating agent, zinc nitrate and urea are respectively dissolved in distilled water, after completely dissolving, the two are mixed, and then the zinc oxide-based conductive oxide is added into the solution, which consists of 92 parts by weight of ZnO, 5.5 parts by weight of Bi 2 o 3 , 2.4 parts by weight of Co 2 o 3 , 0.075 parts by weight of Nb 2 o 5 , 0.025 parts by weight Y 2 o 3 , and its room temperature resistivity is ab...

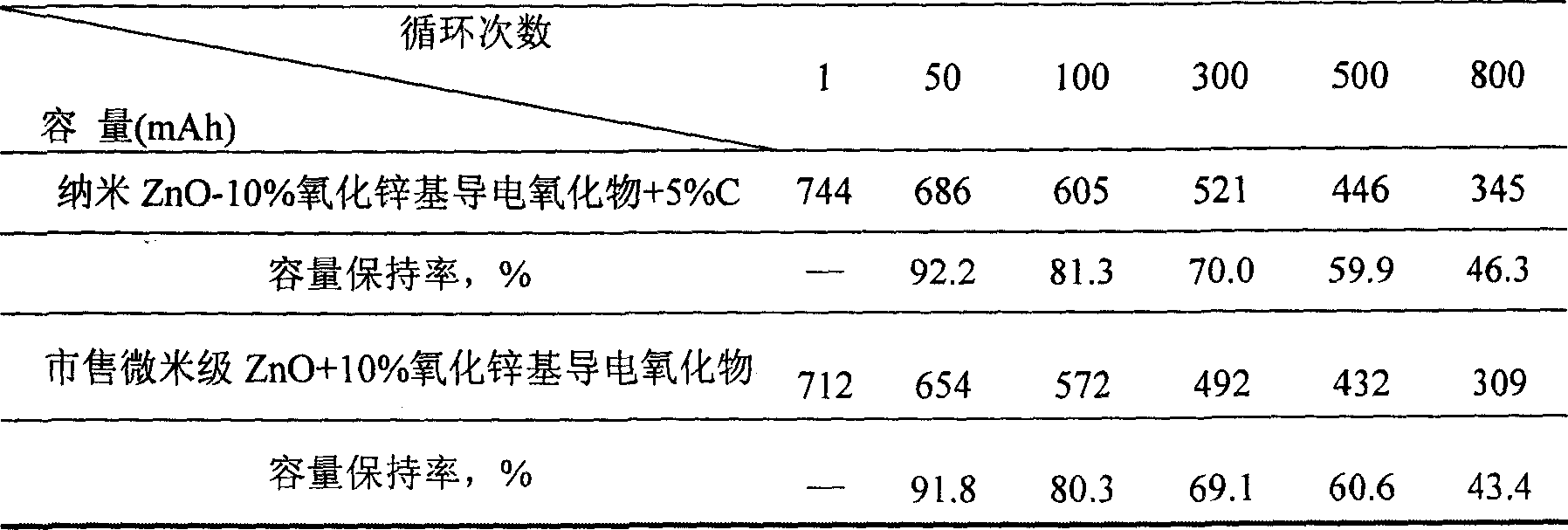

Embodiment 2

[0028] A negative electrode material for an alkaline secondary zinc electrode, with a zinc oxide-based conductive oxide as the inner core, and nano-zinc oxide particles are uniformly wrapped outside the inner core, and the chemical composition of the zinc oxide-based conductive oxide is: 95 Parts by weight of ZnO; 5 parts by weight of Co 2 o 3 .

[0029] Zinc nitrate is used as raw material, ammonia water and urea are used as precipitating agent, zinc nitrate and urea are respectively dissolved in distilled water, after completely dissolving, the two are mixed, and then the zinc oxide-based conductive oxide is added into the solution, which consists of 95 parts by weight of ZnO, 5 parts by weight of Co 2 o 3 , the mass ratio of the zinc oxide-based conductive oxide to the zinc nitrate is 1:59. Heat to 120° C. with ultrasonic stirring and keep warm for 2 hours. After cooling, filter, wash the precipitate with distilled water and ethanol, and then dry at 120°C for 1 hour to...

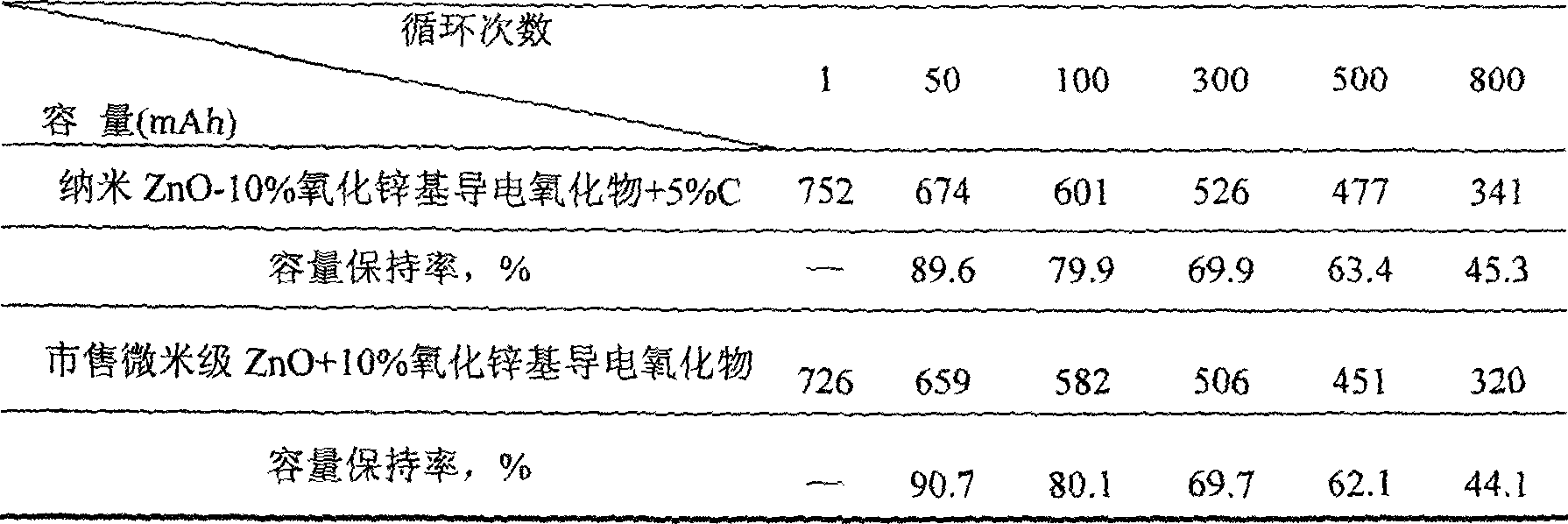

Embodiment 3

[0034] A negative electrode material for an alkaline secondary zinc electrode, with a zinc oxide-based conductive oxide as the inner core, and nanometer zinc oxide particles are evenly wrapped outside the inner core, and the chemical composition of the zinc oxide-based conductive oxide is: 98 Parts by weight of ZnO; 2 parts by weight of Co 2 o 3 .

[0035] Zinc nitrate is used as raw material, ammonia water and urea are used as precipitating agent, zinc nitrate and urea are respectively dissolved in distilled water, after completely dissolving, the two are mixed, and then the zinc oxide-based conductive oxide is added into the solution, which consists of 98 parts by weight of ZnO, 2 parts by weight of Co 2 o 3 , the mass ratio of the zinc oxide-based conductive oxide to the zinc nitrate is 1:40. Heat to 90°C with ultrasonic stirring and keep warm for 3 hours. After cooling, filter, wash the precipitate with distilled water and ethanol, and then dry at 100°C for 3 hours to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com