Secondary zinc electrode additive and its preparing method

An additive and electrode technology, which is applied in the field of secondary zinc electrode additives and its preparation, can solve the problems of reducing the utilization rate and conductivity of the active material of the zinc negative electrode, the improvement effect of the cycle life is not large, and the modification effect is not lasting, etc. Improve comprehensive electrochemical performance, reduce internal resistance and prevent dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A secondary zinc electrode additive, which consists of: 80 parts by weight of ZnO, 5 parts by weight of Bi 2 o 3 , 5 parts by weight of Al 2 o 3 , 10 parts by weight of C (graphite), the particle size of the additive is 0.1-1.0 μm, the graphite powder is natural graphite powder, which contains 10% by mass of short graphite fibers. ZnO, Bi 2 o 3 、Al 2 o 3 , graphite powder and short fibers are weighed according to the proportion, add distilled water and polyacrylamine dispersant, the polyacrylamine dispersant is 3% of the mass of the mixture of oxides and graphite, and mix in a ball mill for 2 hours to form a uniform slurry The substance is then grouted into spherical particles, dried and sintered in a muffle furnace for 2 hours at a temperature of 1500°C to form a powder, then crushed into a powder shape in a ball mill after cooling, and then sieved to obtain a particle size of 0.1~1.0μm secondary zinc electrode additive powder finished product.

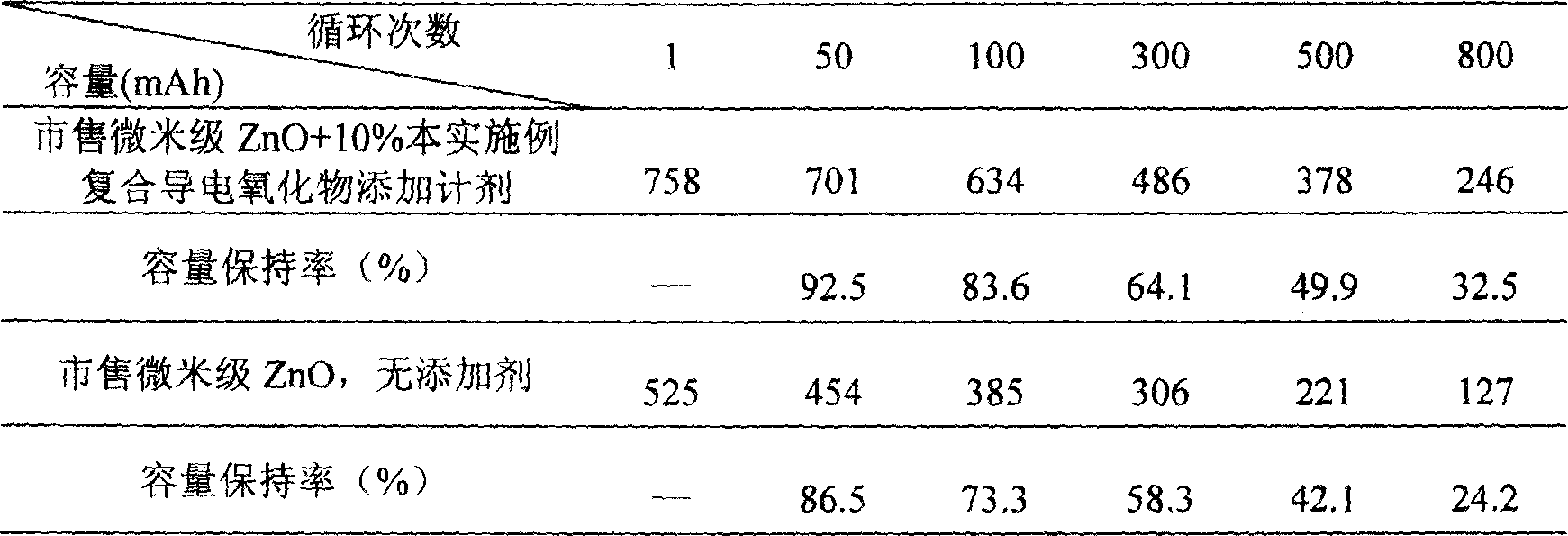

[0028]Add the ...

Embodiment 2

[0032] A secondary zinc electrode additive, its chemical composition is: 80 parts by weight of SnO 2 , 5 parts by weight of Bi 2 o 3 , 5 parts by weight of Al 2 o 3 10 parts by weight of C (graphite), the particle size of the additive is 0.1-1.0 μm, and the graphite powder is natural graphite powder, which contains 10% short graphite fibers. SnO 2 、 Bi 2 o 3 、Al 2 o 3 , graphite powder and short fibers are weighed according to the proportion, add distilled water and polyacrylamine dispersant, the polyacrylamine dispersant is 0.1% of the mass of the mixture of oxides and graphite, and mix in a ball mill for 2 hours to form a uniform slurry The material is then grouted into spherical particles, dried and sintered in a muffle furnace for 3 hours at a temperature of 1500 ° C to form a powder, and then crushed into a powder shape in a ball mill, and then sieved to obtain a particle size of 0.1~1.0μm secondary zinc electrode additive powder finished product.

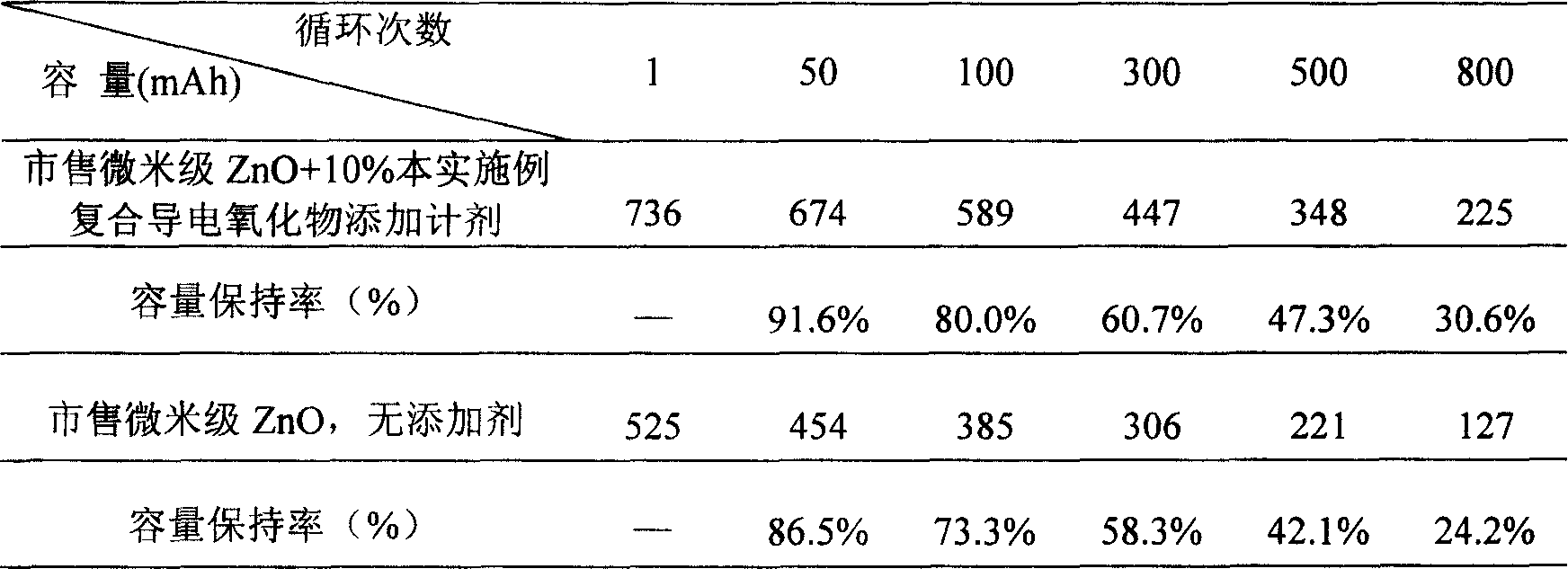

[0033] Add t...

Embodiment 3

[0037] A secondary zinc electrode additive, its chemical composition is: 10 parts by weight of ZnO, 80 parts by weight of SnO 2 10 parts by weight of C (graphite), the particle size of the additive is 0.1-1.0 μm, and the graphite powder is natural graphite powder, which contains 10% short graphite fibers. ZnO, SnO 2 , graphite powder and short fibers are weighed according to the proportion, add distilled water and polyacrylamine dispersant, the polyacrylamine dispersant is 0.5% of the mixture mass of each oxide and graphite, and ball mill in a ball mill for 1.5 hours to form a uniform slurry After being dried, it is sintered in a muffle furnace at a temperature of 1200°C for 6 hours, and after cooling, it is crushed into a powder shape in a ball mill, and then sieved to obtain the particle size. It is a finished product of secondary zinc electrode additive powder with a thickness of 0.1-1.0 μm.

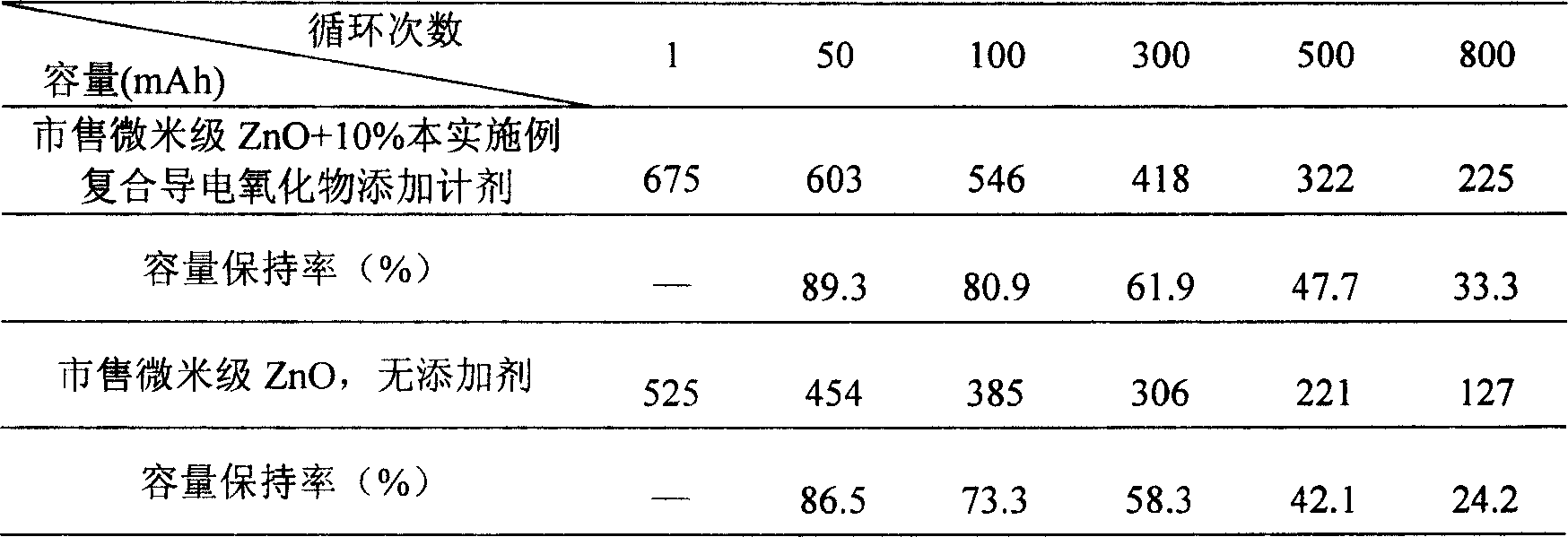

[0038] Add the prepared secondary zinc electrode additive powder to zinc oxide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com