A kind of chitosan hollow microcapsule and preparation method thereof

A technology for microcapsules and chitosan, applied in the field of chitosan hollow microcapsules and the preparation thereof, can solve the problems of damage to the integrity of the capsule wall, cumbersome preparation process, practical application limitations, etc., and achieves narrow particle size distribution and simple process. , the effect of increasing the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

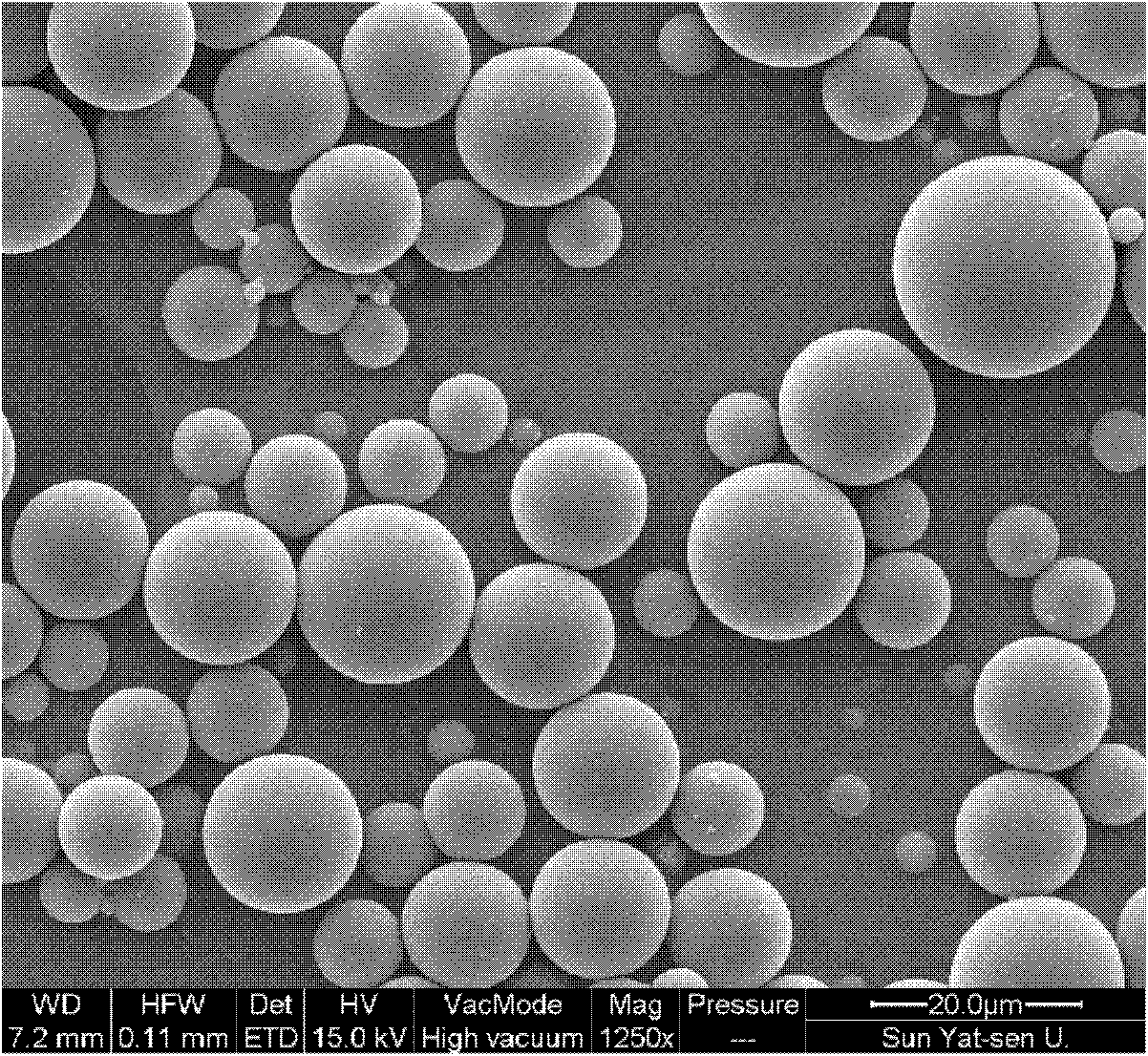

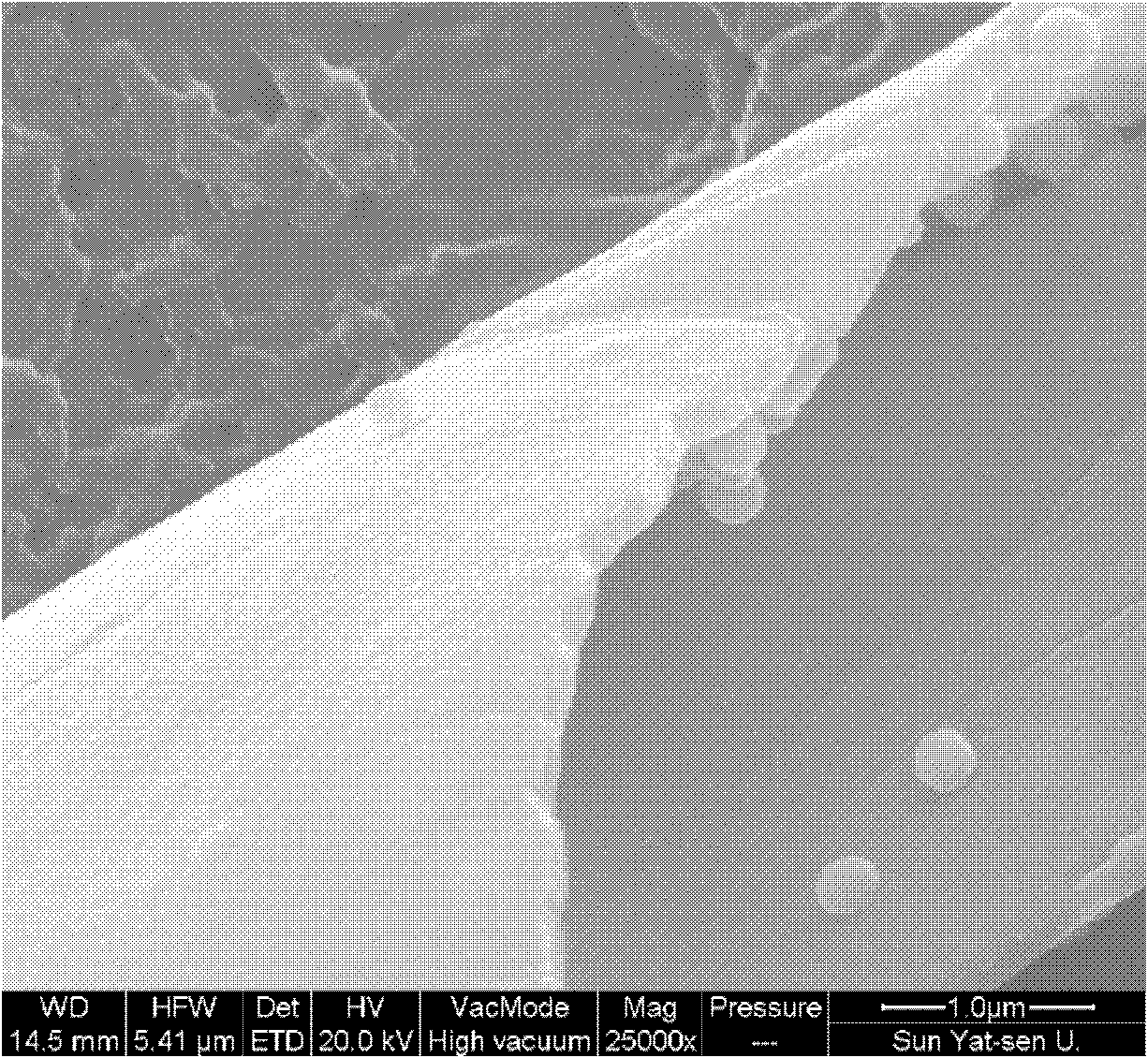

[0032] 5g of chitosan with a degree of deacetylation of 90% is dissolved in 100ml containing 0.1mol / L acetic acid, and this solution is added in 100ml of liquid paraffin, which also contains an emulsifier: 0.05g of dodecylbenzenesulfonic acid Sodium and 0.05g surfactant (OP-10), above-mentioned solution is with emulsifying machine with 10 4 Disperse at the speed of rpm for 5 minutes, add 30ml of 0.1mol / L copper sulfate solution under mechanical stirring, add 2g of glutaraldehyde solution after 10 minutes, react at 40°C for 3 hours, filter the product, wash with ethanol and deionized water Put it into the chromatography column, wash it successively with 10ml 0.1mol / L hydrochloric acid solution, 10ml 0.1mol / L sodium hydroxide solution and 100ml deionized water, and dry the fully washed product to obtain the required hollow microsphere. Capsule (scanning electron micrograph, such as figure 1 , figure 2 shown), with an average diameter of 13 μm and a wall thickness of 0.2 μm. ...

Embodiment 2

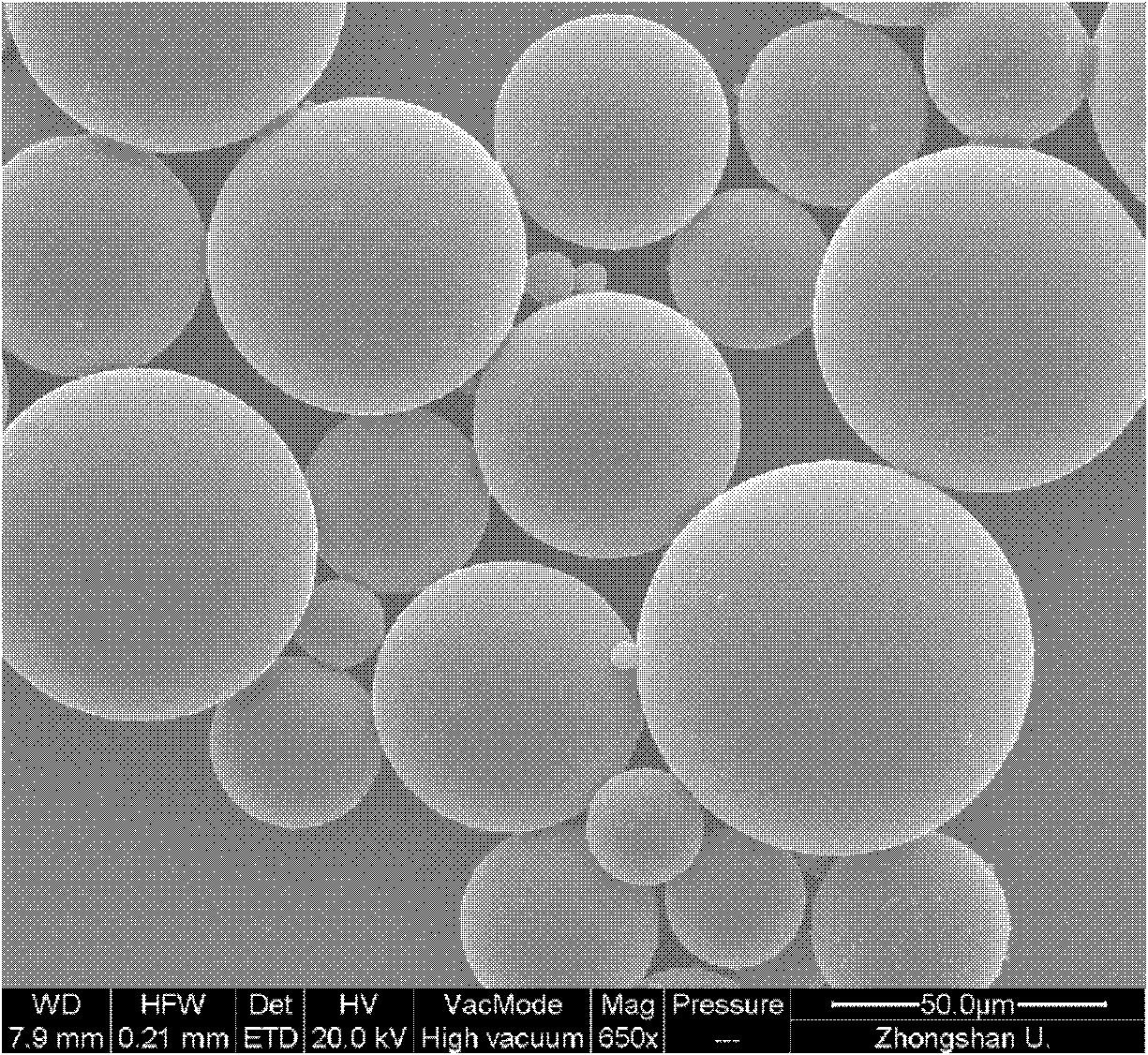

[0034] 15g of O-hydroxyethylated chitosan with 98% degree of deacetylation is dissolved in 500ml of dichloroacetic acid containing 0.05mol / L, and this solution is added to the mixed solution of dichloromethane and toluene in a ratio of 1:1 In 500ml, also contain emulsifier in the mixed solution of this dichloromethane and toluene: 0.5g sodium lauryl sulfate and 0.2g Tween-85, above-mentioned solution is with emulsifying machine with 10 3 Disperse at the speed of rpm for 5 minutes, add 50ml of 0.9mol / L cobalt chloride solution under mechanical stirring, add 1g of glutaraldehyde and 1g of diphenylmethane diisocyanate after 10 minutes, react at 30°C for 5h, filter the product, After washing with ethanol and deionized water, put it into the chromatography column, wash it successively with 20ml 0.05mol / L hydrochloric acid solution, 20ml 0.05mol / L sodium hydroxide solution and 200ml deionized water, and wash the fully washed product The desired hollow microcapsules can be obtained a...

Embodiment 3

[0036] 2g degree of deacetylation is that 88% O-hydroxypropylated chitosan is dissolved in 300ml containing 0.5mol / L acrylic acid, this solution is added to isooctane and hexanaphthene mixed solution 300ml by 1: 1 ratio Among them, the mixed solution of isooctane and cyclohexane also contains emulsifier: 4g nonylphenol polyoxyethylene ether sulfate triethanolamine salt and 1g castor oil polyoxyethylene (90) ether, and the above-mentioned solution is mixed with an emulsifier at 10 5Disperse at the speed of rpm for 5 minutes, add 40ml of 0.5mol / L manganese chloride solution under mechanical stirring, add 2g of formaldehyde solution and 1g of toluene diisocyanate after 10 minutes, react at 45°C for 4 hours, filter the product, and remove it with ethanol and After washing with ionic water, put it into a chromatography column, wash it successively with 100ml 0.01mol / L hydrochloric acid solution, 100ml 0.01mol / L sodium hydroxide solution and 300ml deionized water, and dry the fully w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com