High-temperature speckle and controllable preparation method

A speckle and high-temperature technology, which is applied in the field of high-temperature speckle and its controllable preparation, can solve the problems of low preparation efficiency, high preparation requirements, and speckle failure, so as to improve low-temperature curing performance, high-temperature resistance, and good high-temperature resistance Performance and high-temperature adsorption performance, the effect of improving the speckle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further elaborated below through specific embodiments in conjunction with the accompanying drawings.

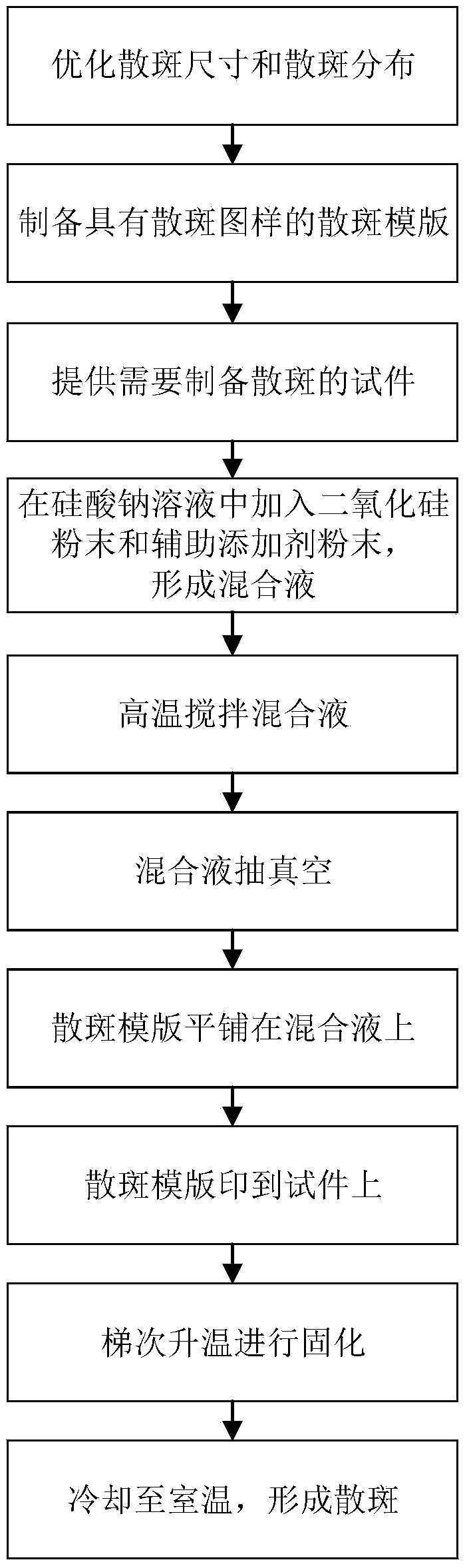

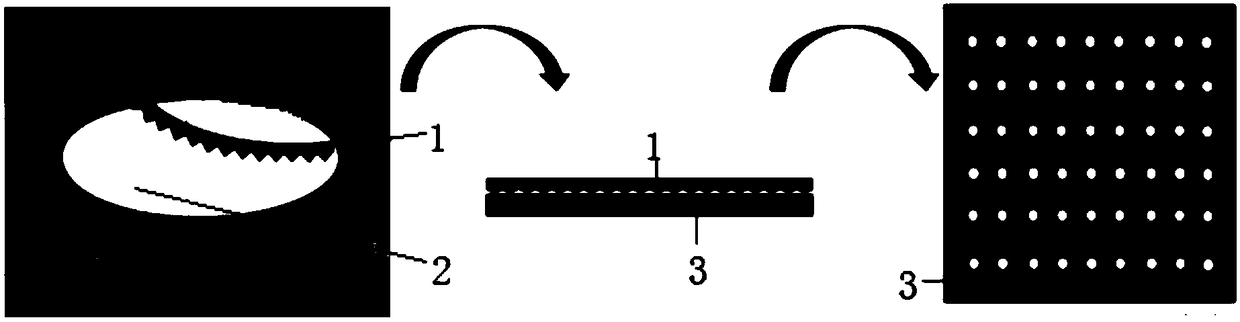

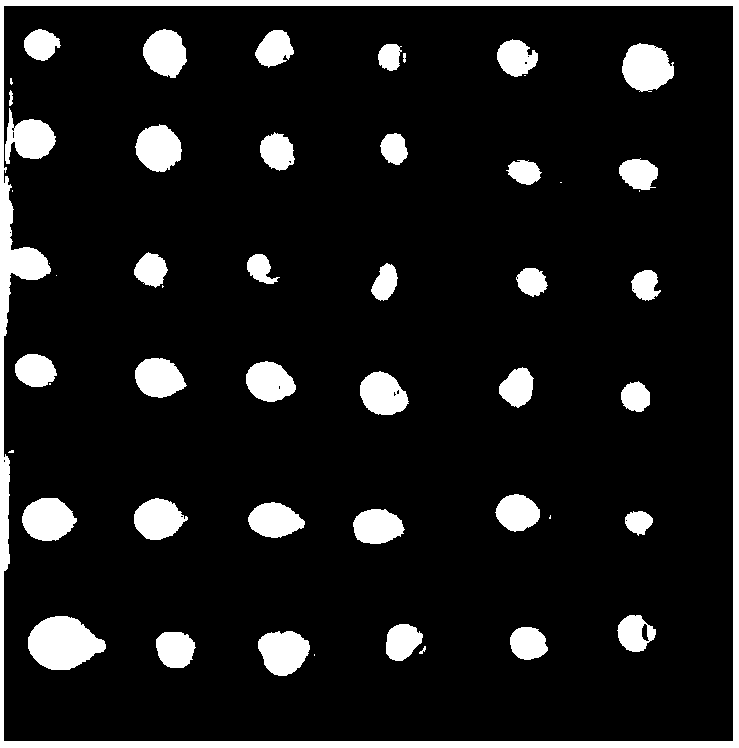

[0047] like figure 1 and 2 As shown, the adjustable preparation method of high-temperature speckle in this embodiment includes the following steps:

[0048] 1) Using the average gray gradient δ f Optimize the actual speckle size and speckle distribution;

[0049] 2) According to the optimized speckle size and speckle distribution, 3D printing technology is used to prepare a speckle template 1 with a speckle pattern. The raised position on the speckle template is the spot of the speckle, and the material of the speckle template is resin ;

[0050] 3) Process the Inconel 713C nickel-based superalloy specimen to the required size, use sandpaper of different meshes to cross-polish the speckle-coated side of the specimen surface, and then wipe the surface of the specimen with alcohol and dry it; The mesh numbers of the sandpaper used are 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com