Method for improving dispersibility of graphene in polymer matrix

A graphene and polymer technology, applied in the field of improving the dispersibility of graphene in a polymer matrix, can solve the problems of weakening some properties of materials, requiring organic solvents, low efficiency, etc., achieving excellent comprehensive performance, easy access to equipment, Equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

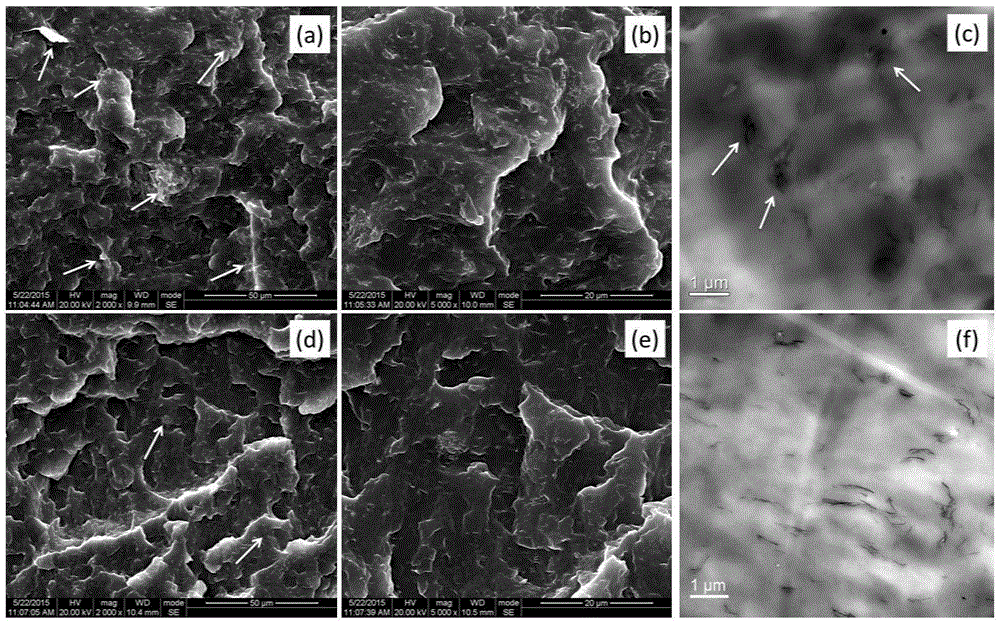

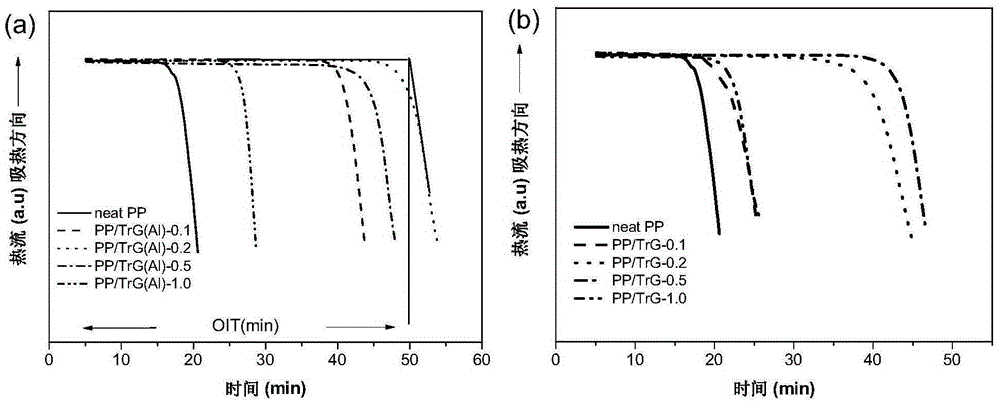

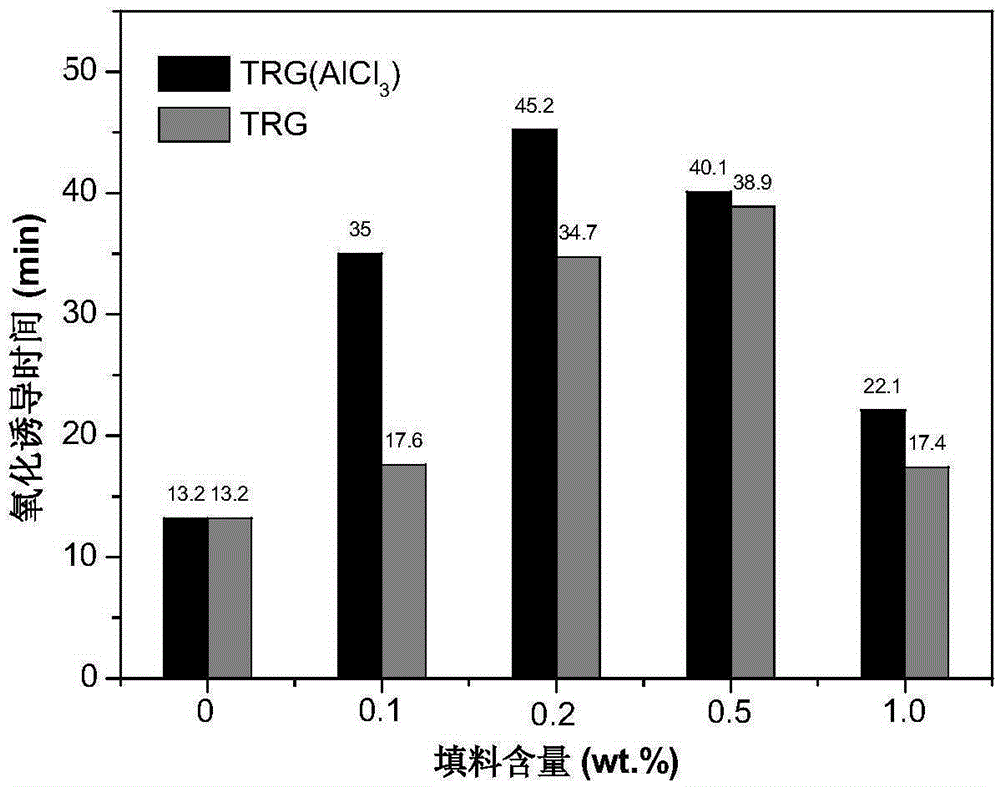

[0041] Aluminum trichloride (AlCl 3 ) as a catalyst was added to the melt blending system of isotactic polypropylene (PP) and thermally reduced graphene (TrG) to prepare a PP / TrG composite material masterbatch with a high content of TrG. After extraction, the catalyst in the masterbatch was removed, and then the masterbatch was blended with PP to obtain a PP / TrG composite material with a lower TrG content. The specific raw materials and their weight ratios are shown in Table 1.

[0042] The specific preparation method is as follows:

[0043] The first step, at first prepare raw materials by above-mentioned components;

[0044] In the second step, the isotactic PP and thermally reduced graphene (TrG) were dried in an oven at 60°C for 12 hours;

[0045] Then, put the isotactic PP and TrG obtained in the second step into the torque rheometer for banburying and mixing for 2 minutes, and then add AlCl 3 Add it into the blending system and mix for 10 minutes, the processing tempe...

Embodiment 2-13

[0069] The raw materials of embodiment 2-13 and their weight ratio are shown in table 1, and its preparation method is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com