Drying and melting process of preparing LiMn2O4 latex as positive electrode material for lithium ion battery

A technology for lithium-ion batteries and cathode materials, applied in electrode manufacturing, battery electrodes, negative electrodes, etc., can solve problems such as poor high-current discharge performance, short cycle life, and difficulty in popularization and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

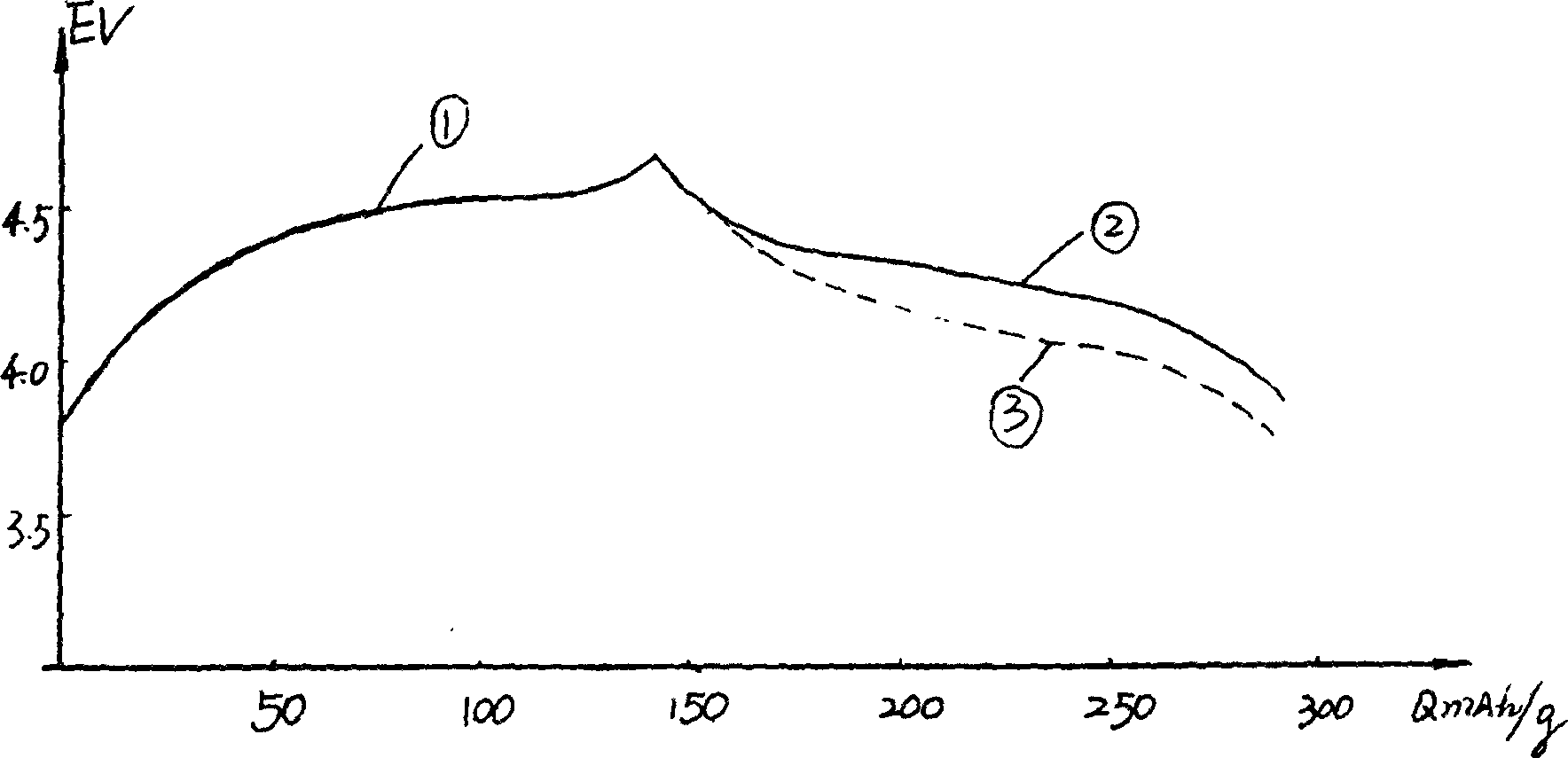

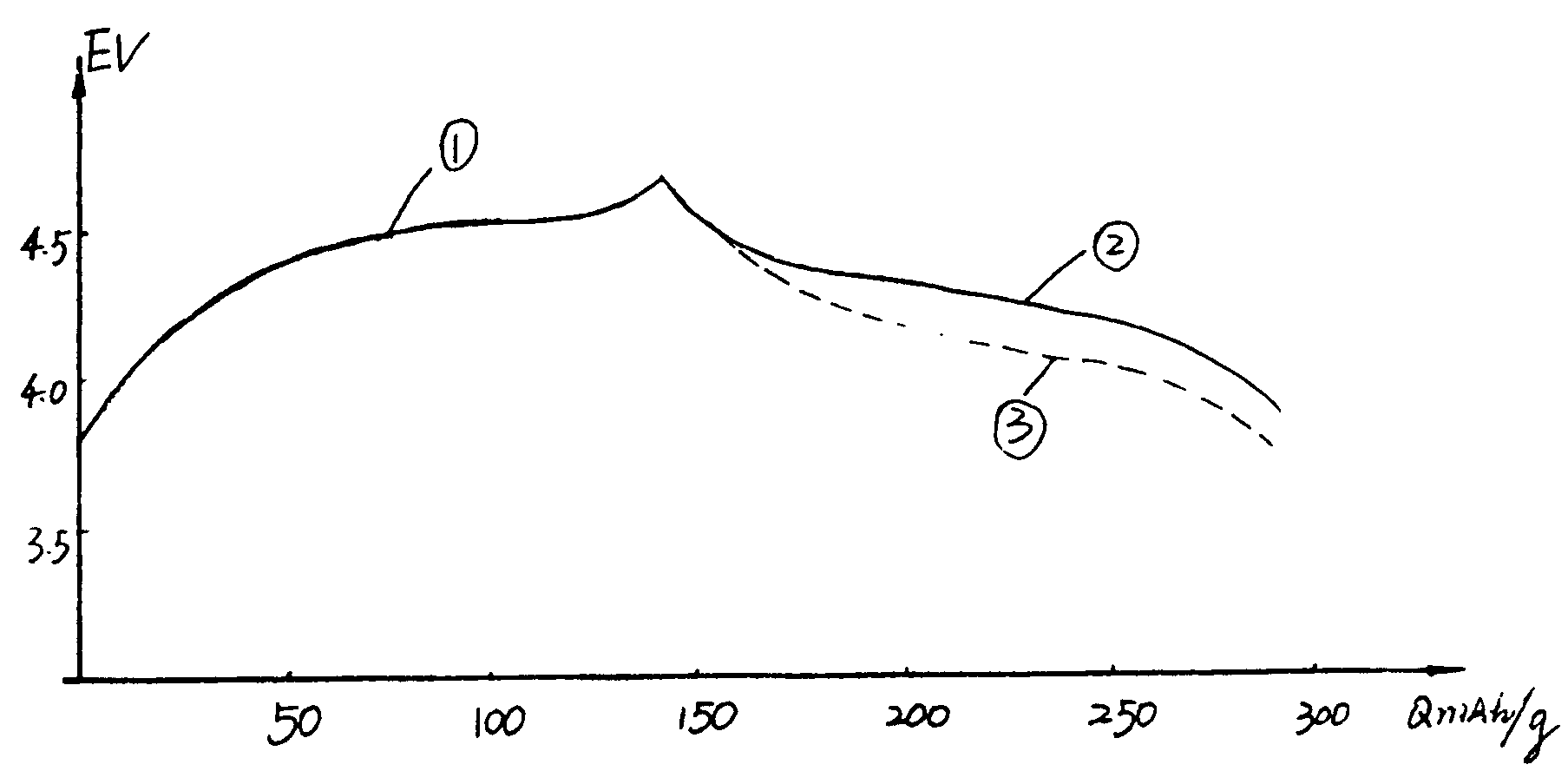

Image

Examples

Embodiment Construction

[0004] The technical measures taken for realizing the purpose of the present invention are:

[0005] 1. Principle of material preparation

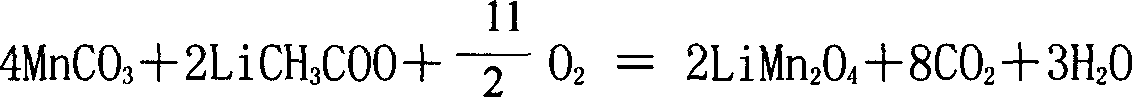

[0006] Synthesis of LiMn 2 o 4 Manganese carbonate (MnCO 3 ) and lithium acetate (LiCH 3 COO) as raw material, the basic synthesis reaction is

[0007]

[0008] 2. Synthetic material formula

[0009] According to the correct composition and content of the raw materials, the lithium / manganese molar ratio is 0.5, and the total weight ratio is 1%. 2+ 、Co 3+ , Mg 2+ Ion and mixed glue composed of polyvinylidene fluoride (PVDF) and polyvinyl alcohol (PVA), wherein the weight of polyvinylidene fluoride (PVDF) accounts for 15-20% of the total weight of the glue.

[0010] 3. Synthesis process

[0011] According to the above formula, the raw materials are mixed into latex and dried at 200°C for 5-7 hours, then reacted in a molten state at 850°C for 10 hours, cooled and taken out, and then powdered to obtain LiMn 2 o 4 Cathode powder. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com