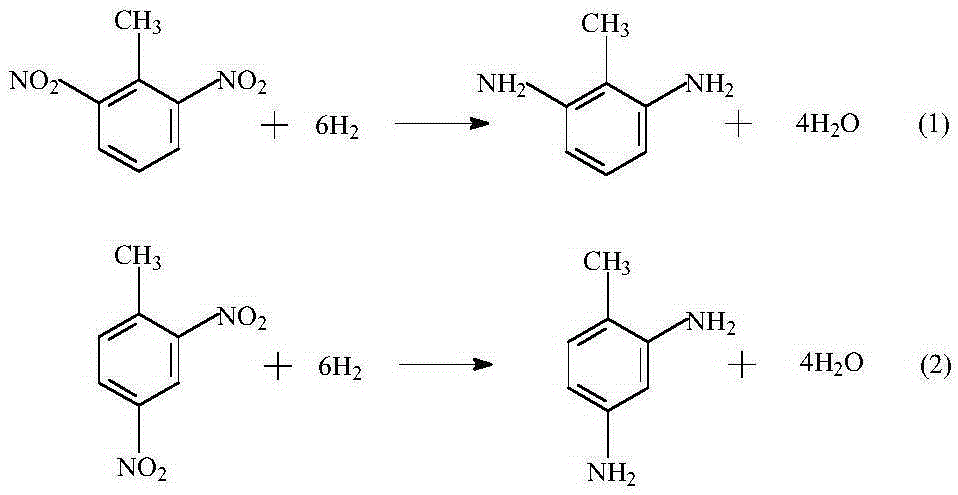

Raney nickel catalyst for low-pressure hydrogenation of dinitrotoluene and its preparation method and application

A dinitrotoluene and catalyst technology, which is applied in the fields of Raney-type catalysts, amino compound preparation, physical/chemical process catalysts, etc., can solve the problems of large equipment investment, expensive catalysts, and high reaction pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

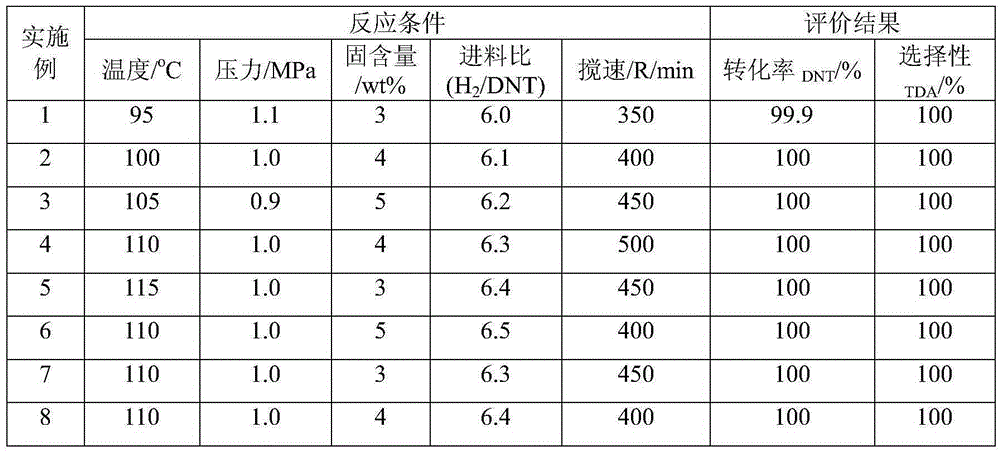

Examples

Embodiment 1

[0044] (1) Mix the 6μm nickel powder, 5μm Al powder and 8μmCr powder uniformly in the mass ratio of Ni55wt%-Al40wt%-Fe5wt%, and then place them in a crucible with SiC inlaid around and a leak at the bottom, and place the above crucible in a microwave oven In the Ar atmosphere of 0.8MPa, the temperature is increased to 1600°C at a rate of 80°C / min to melt, and then the molten alloy is sent to the atomization chamber through the funnel under the pressure of Ar gas, and is in the atomization chamber through the heat preservation nozzle Carry out the secondary cooling of gasification atomization and centrifugal atomization, the rotating disk speed of centrifugal atomization is 4000R / min, and the cooling rate is 1×10 6 K / s, then dried and sieved to obtain alloy powder with a particle size of 80-100 mesh;

[0045] (2) Mix the above-prepared alloy powder and sodium hydroxide solids and place them in a container. The mass ratio of sodium hydroxide and alloy powder is 1:1. Under normal tem...

Embodiment 2

[0050] (1) Mix the 3μm nickel powder, 7μm Al powder and 7μm iron powder uniformly in the mass ratio of Ni54wt%-Al42wt%-Fe4wt%, and then place them in a crucible with SiC inlaid around and a leak at the bottom. In a microwave oven, in an Ar atmosphere of 0.9MPa, the temperature is increased to 1550°C at a rate of 70°C / min to melt, and then the molten alloy is sent to the atomization chamber under the pressure of Ar gas, and is carried out in the atomization chamber through a heat preservation nozzle Two-stage cooling for gasification atomization and centrifugal atomization, the rotating disk of centrifugal atomization is 4500R / min, and the cooling rate is 1.2×10 6 K / s, then dried and sieved to obtain alloy powder with a particle size of 100-120 mesh;

[0051] (2) Mix the sodium hydroxide solid prepared above and alloy powder uniformly and place it in a container. The mass ratio of sodium hydroxide and alloy powder is 1.1:1. Under normal temperature conditions, add distilled water a...

Embodiment 3

[0055] (1) Mix 4μm nickel powder, 9μm Al powder and 6μmMo powder with a mass ratio of Ni53wt%-Al45wt%-Mo2wt%, and then place them in a crucible with SiC inlaid around and a leak at the bottom, and place the above crucible in a microwave oven In the Ar atmosphere of 1.0MPa, the temperature is increased to 1500°C at a rate of 60°C / min to melt, and then the molten alloy is sent to the atomization chamber under the pressure of Ar gas, and gas is carried out in the atomization chamber through the heat preservation nozzle. The two-stage cooling of chemical atomization and centrifugal atomization, the rotating speed of centrifugal atomization is 5000R / min, and the cooling rate is 1.3×10 6 K / s, then dried and sieved to obtain alloy powder with a particle size of 120-140 mesh;

[0056] (2) Mix the sodium hydroxide solid prepared above and alloy powder uniformly and place it in a container. The mass ratio of sodium hydroxide to alloy powder is 1.2:1. Add distilled water at a rate of 3ml / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com