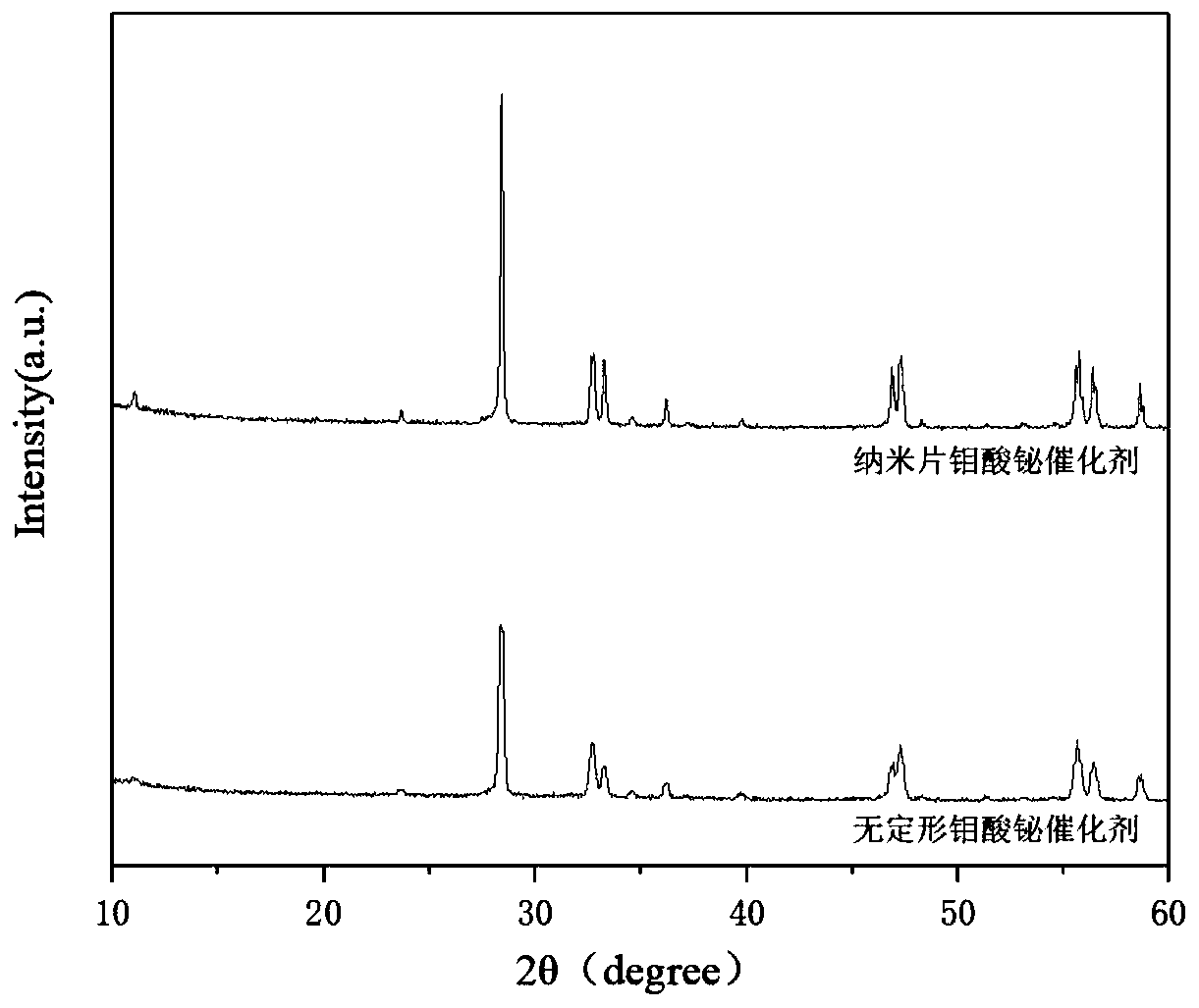

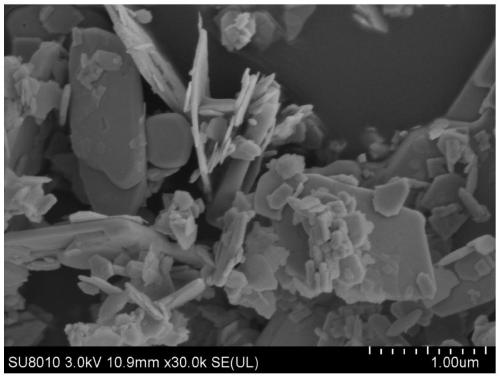

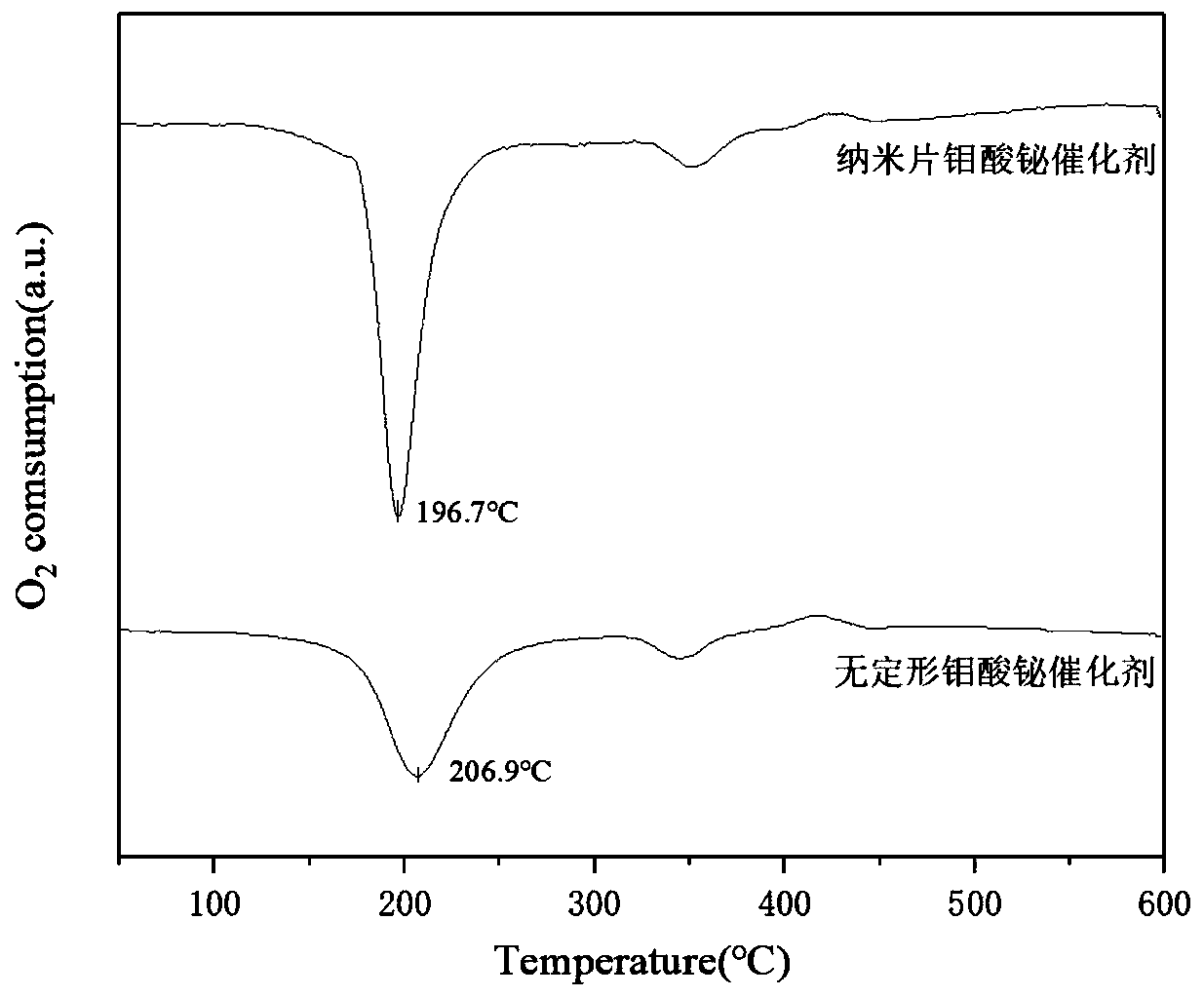

Application of bismuth molybdate catalyst with nanosheet structure in catalytic synthesis of 1,3-butadiene

A technology of nanosheets and catalysts, which is applied in the field of catalytic synthesis 1, bismuth molybdate catalysts, can solve problems that have not been studied before, and achieve the effects of excellent effect, good stability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Catalyst preparation process:

[0027] 1.2125g Bi(NO 3 ) 3 ·5H 2 O was dissolved in 40ml of deionized water, recorded as solution A, 0.2207g (NH 4 ) 6 Mo 7 o 24 4H 2 O was dissolved in 10ml of deionized water, which was recorded as solution B. Under the condition of magnetic stirring, the solutions of A and B were transferred to a 100ml vessel lined with polytetrafluoroethylene. After fully stirring, the pH of the mixed solution was adjusted with ammonia water to 5. Continue stirring for half an hour. The container was sealed and placed in an oven for hydrothermal reaction at a temperature of 180° C. for 18 hours. The reaction product was collected, centrifuged, washed and dried, then calcined in a muffle furnace at 500° C. for 4 hours, ground and sieved after cooling to obtain a bismuth molybdate nanosheet catalyst of 40-60 mesh.

[0028] Oxidative dehydrogenation reaction process:

[0029] 1 g of the above catalyst was filled into a stainless steel reactor w...

Embodiment 2

[0032] Catalyst preparation process:

[0033] 1.2125g Bi(NO 3 ) 3 ·5H 2 O was dissolved in 50ml of deionized water, recorded as solution A, 0.2207g (NH 4 ) 6 Mo 7 o 24 4H 2 Dissolve O in 10ml of deionized water and record it as solution B. Under magnetic stirring conditions, transfer A and B solutions to a 100ml container with a polytetrafluoroethylene liner. After fully stirring, adjust with 3mol / L NaOH solution. The pH of the mixture was 6, and stirring was continued for half an hour. After sealing the container, place it in an oven to carry out hydrothermal reaction, the hydrothermal reaction temperature is 180°C, and the time is 20h. The reaction product was collected, centrifuged, washed and dried, then calcined in a muffle furnace at 500° C. for 4 hours, ground and sieved after cooling to obtain a bismuth molybdate nanosheet catalyst of 40-60 mesh.

[0034] Oxidative dehydrogenation reaction process:

[0035] 1 g of the above catalyst was filled into a stainles...

Embodiment 3

[0038] Catalyst preparation process:

[0039] 1.2125g Bi(NO 3 ) 3 ·5H 2 O was dissolved in 55ml of deionized water, recorded as solution A, 0.2207g (NH 4 ) 6 Mo 7 o 24 4H 2O was dissolved in 5ml of deionized water, which was recorded as solution B. Under the condition of magnetic stirring, the solutions of A and B were transferred to a 100ml vessel lined with polytetrafluoroethylene. After fully stirring, the pH of the mixed solution was adjusted with ammonia water to 6. Continue stirring for half an hour. The container was sealed and placed in an oven for hydrothermal reaction at a temperature of 160° C. for 24 hours. The reaction product was collected, centrifuged, washed and dried, then calcined in a muffle furnace at 550° C. for 3 hours, ground and sieved after cooling to obtain a bismuth molybdate nanosheet catalyst of 40-60 mesh.

[0040] Oxidative dehydrogenation reaction process:

[0041] 1 g of the above catalyst was filled into a stainless steel reactor wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com