Preparation method of blast furnace slag-based composite material

A composite material and blast furnace slag technology, which is applied in the field of industrial waste slag recycling and reuse, can solve the problems of high development and utilization costs and low resource utilization efficiency of blast furnace slag, and achieve the effects of high-efficiency preparation, reduced reaction time, and reduced consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

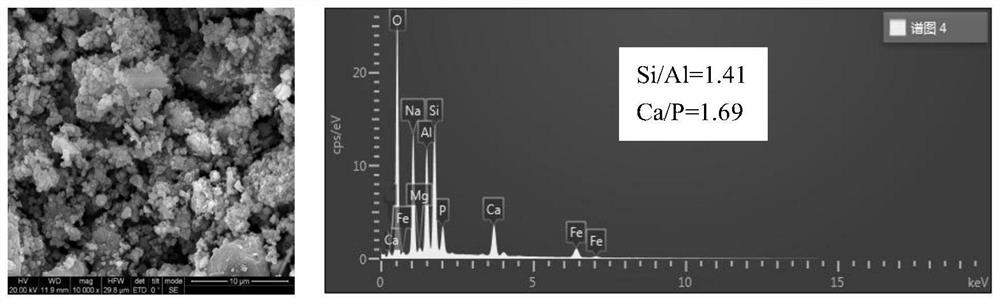

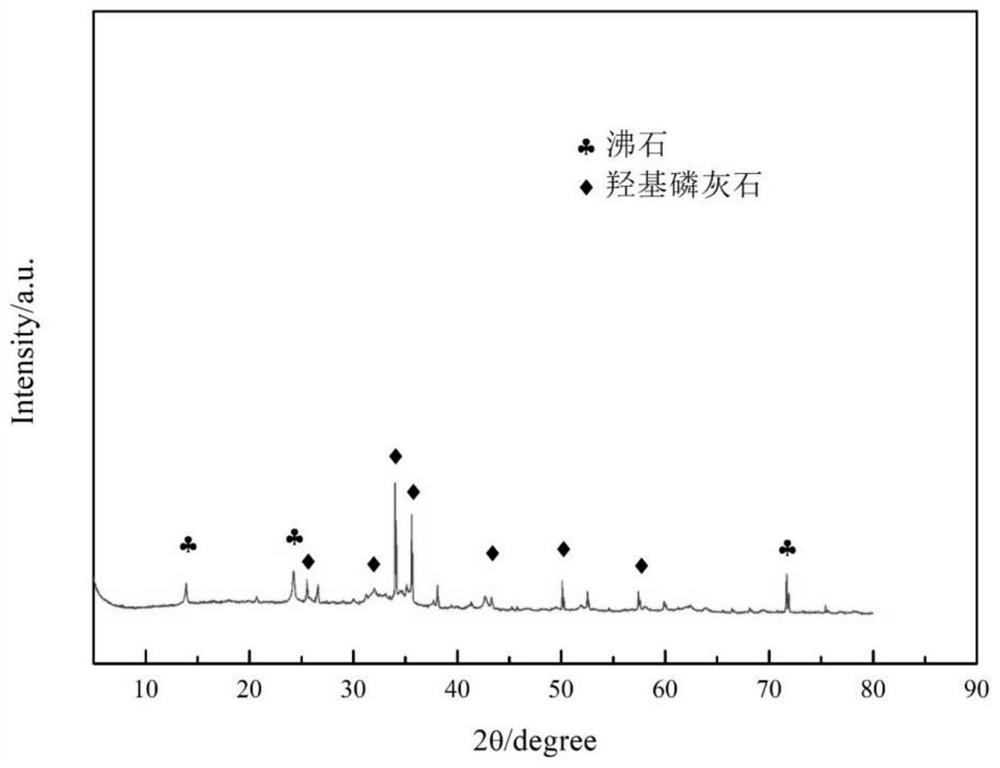

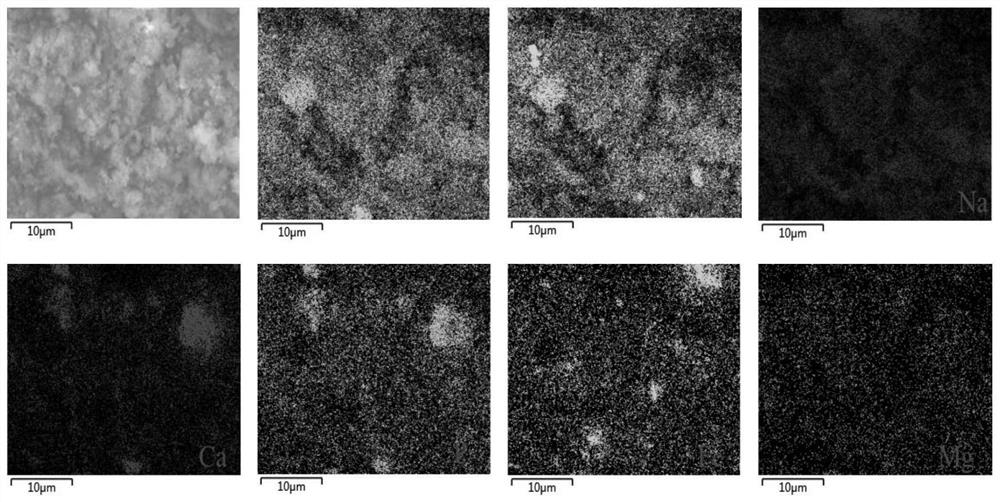

[0034] Blast furnace slag is collected from a Jiangsu Iron and Steel Co., Ltd., and its main component content is: SiO 2 29.13%, CaO47.08%, Al 2 o 3 20.59%, MgO 1.11%. The preparation steps of the blast furnace slag-based hydroxyapatite-zeolite composite material are as follows:

[0035] (1) Evenly mix blast furnace slag and sodium hydroxide at a mass ratio of 1:1.3, and melt at 600°C for 60 minutes to obtain a molten product;

[0036](2) Under the condition that the Ca / P molar ratio of the reaction system is 10:6, transfer the molten product obtained in step (1) to a three-necked flask and add 30mL 2.0mol / L disodium hydrogen phosphate solution, stir well Then, continue to add 50mL 2.0mol / L NaOH solution, stir vigorously at 100°C for 1h, and then crystallize for 6h;

[0037] (3) After the crystallization in step (2) is completed, the product is taken out and filtered, the filter cake is washed with water until neutral, and dried at 80°C for 3 hours to obtain a blast furna...

Embodiment 2

[0039] The blast furnace slag is the same as in Example 1, and the preparation steps of the blast furnace slag-based hydroxyapatite-zeolite composite material are as follows:

[0040] (1) Evenly mix blast furnace slag and sodium hydroxide particles at a mass ratio of 1:1.3, and melt at 550°C for 60 minutes to obtain a molten product;

[0041] (2) Under the condition that the Ca / P molar ratio of the reaction system is 10:6, transfer the molten product obtained in step (1) to a three-necked flask and add 30mL 2.0mol / L sodium dihydrogen phosphate solution, and stir evenly Then, continue to add 50mL 2.0mol / L NaOH solution, stir vigorously at 100°C for 2h, and then crystallize for 8h;

[0042] (3) After the crystallization in step (2) is completed, the product is taken out and filtered, the filter cake is washed with water until neutral, and dried at 80° C. for 3 hours to obtain a blast furnace slag-based hydroxyapatite-zeolite composite material. The microscopic morphology, phase...

Embodiment 3

[0044] The blast furnace slag is the same as in Example 1, and the preparation steps of the blast furnace slag-based hydroxyapatite-zeolite composite material are as follows:

[0045] (1) Evenly mix blast furnace slag and sodium hydroxide particles at a mass ratio of 1:1.2, and melt at 500°C for 120 minutes to obtain a molten product;

[0046] (2) Under the condition that the Ca / P molar ratio of the reaction system is 10:6, transfer the molten product obtained in step (1) to a three-necked flask and add 30mL 2.0mol / L sodium dihydrogen phosphate solution, and stir evenly Then, continue to add 50mL 2.0mol / L NaOH solution, stir vigorously at 100°C for 2h, and then crystallize for 6h;

[0047] (3) After the crystallization in step (2) is completed, the product is taken out and filtered, the filter cake is washed with water until neutral, and dried at 80° C. for 3 hours to obtain a blast furnace slag-based hydroxyapatite-zeolite composite material. The microscopic morphology, phas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com