A kind of preparation method of high-performance cerium-zirconium solid solution material

A cerium zirconium solid solution, high-performance technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of uneven crystal phase distribution, small specific surface area, low catalytic activity, etc. The effect of large surface area and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

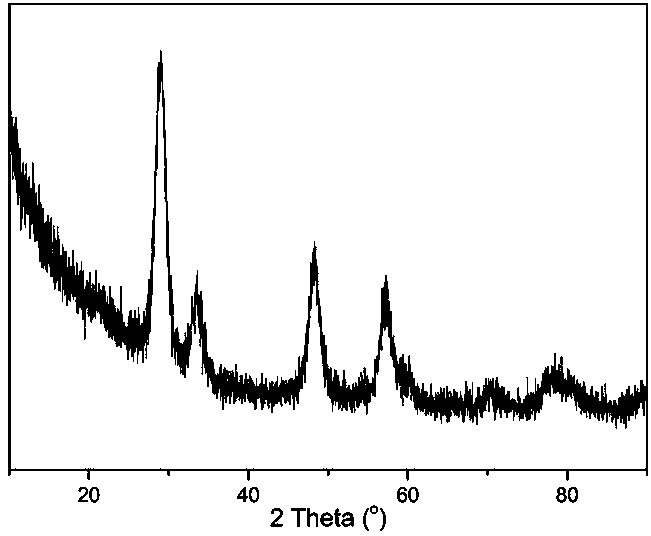

[0019] Add 1.09g of cerium nitrate hexahydrate and 0.14g of anhydrous zirconium nitrate (4:1 molar ratio) into a beaker containing 100ml of deionized water, and add 5g of surfactant polyethylene glycol-200, and stir for 30min; Adopt the method of two-fluid spray, use compressed air as the gas component, set the air pressure to 0.4bar, feed rate to 0.01L / min, mix the ammonia solution with the concentration of 1.0mol / L with the above solution, and at the same time vigorously Stir to adjust the pH of the solution to about 10; after continuing to stir for 1 hour, transfer the mixed solution in the beaker to a 250ml stoppered flask, and put it into a constant temperature water bath at 60°C for hydrothermal aging treatment, and the treatment time is 4 hours; then filter and wash the precipitate with deionized water, dry the precipitate at 80°C for 6-8h; then roast the solid at 700°C in an air atmosphere for 4h with a heating rate of 5°C / min to obtain fresh cerium-zirconium Solid sol...

Embodiment 2

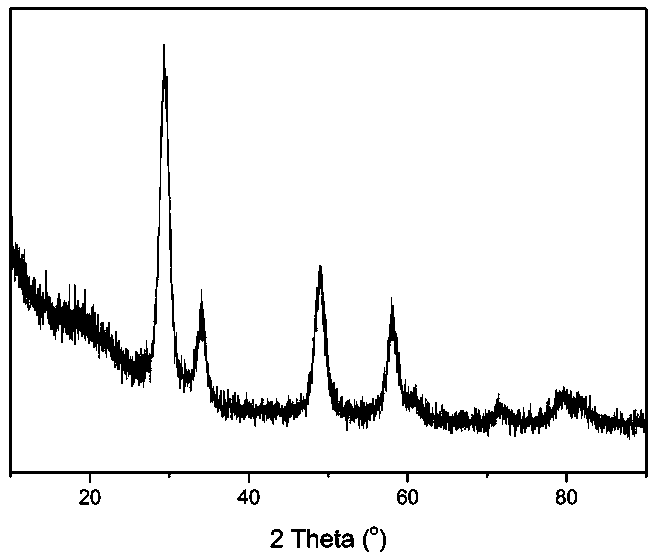

[0021] Add 1.37g of ceric ammonium nitrate and 0.58g of anhydrous zirconium nitrate (1:1 molar ratio) into a beaker containing 100ml of deionized water, and add 20g of surfactant polyethylene glycol-400, and stir for 30min; then use Two-fluid spray method, with compressed air as the gas component, set the air pressure to 0.4bar, and the feed rate to 0.01L / min, mix the ammonia solution with a concentration of 1.0mol / L with the above solution, and stir vigorously at the same time , adjust the pH of the solution to about 7; after continuing to stir for 1 hour, transfer the mixed solution in the beaker into a 250ml stoppered flask, and put it into a constant temperature water bath at 80°C for hydrothermal aging treatment, and the treatment time is 18 hours ; After that, filter and wash the precipitate with deionized water, dry the precipitate at 80°C for 6-8h; then roast the solid at 700°C in an air atmosphere for 4h, with a heating rate of 5°C / min, to obtain a fresh cerium-zirconi...

Embodiment 3

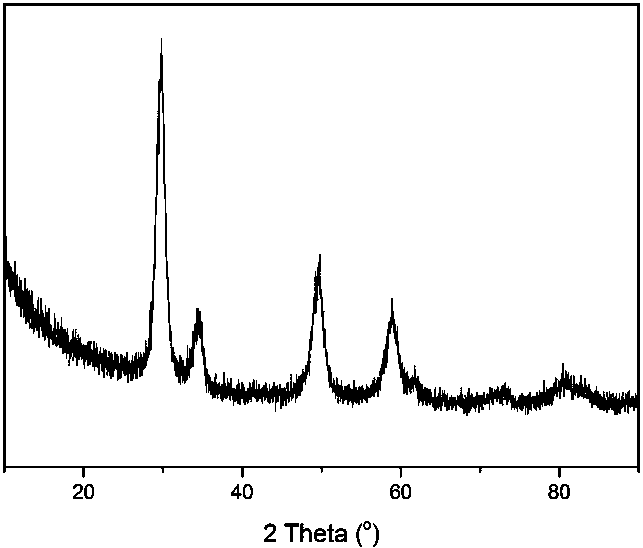

[0023] Add 0.18g of cerous chloride heptahydrate and 0.64g of zirconium oxychloride octahydrate (1:4 molar ratio) into a beaker containing 100ml of deionized water, and add 10g of surfactant dodecanoic acid, and stir for 30min; Then adopt the mode of two-fluid spray, with compressed air as the gas component, set the pressure of air as 0.6bar, feed rate as 0.1L / min, the ammonia solution with the concentration of 4.0mol / L is mixed with the above solution, and at the same time add Stir vigorously to adjust the pH of the solution to about 10; after continuing to stir for 1 hour, transfer the mixed solution in the beaker into a 250ml stoppered flask, and put it in a constant temperature water bath at 90°C for hydrothermal aging treatment. 24 hours; then filter and wash the precipitate with deionized water, dry the precipitate at 100°C for 6-8h; then roast the solid at 700°C in an air atmosphere for 4h with a heating rate of 5°C / min to obtain fresh cerium Zirconium solid solution sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com