Method for modifying and dyeing polyester fiber by use of silver-doped nano titanium dioxide disperse dye

A nano-titanium dioxide and polyester fiber technology, which is applied in fiber treatment, textiles and papermaking, etc., can solve the problems of polyester fiber's poor hand feeling and air permeability, low photocatalytic activity of polyester fiber, and unsustainable washing resistance, etc., and shorten the production process process, high photocatalytic activity and antimicrobial properties, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

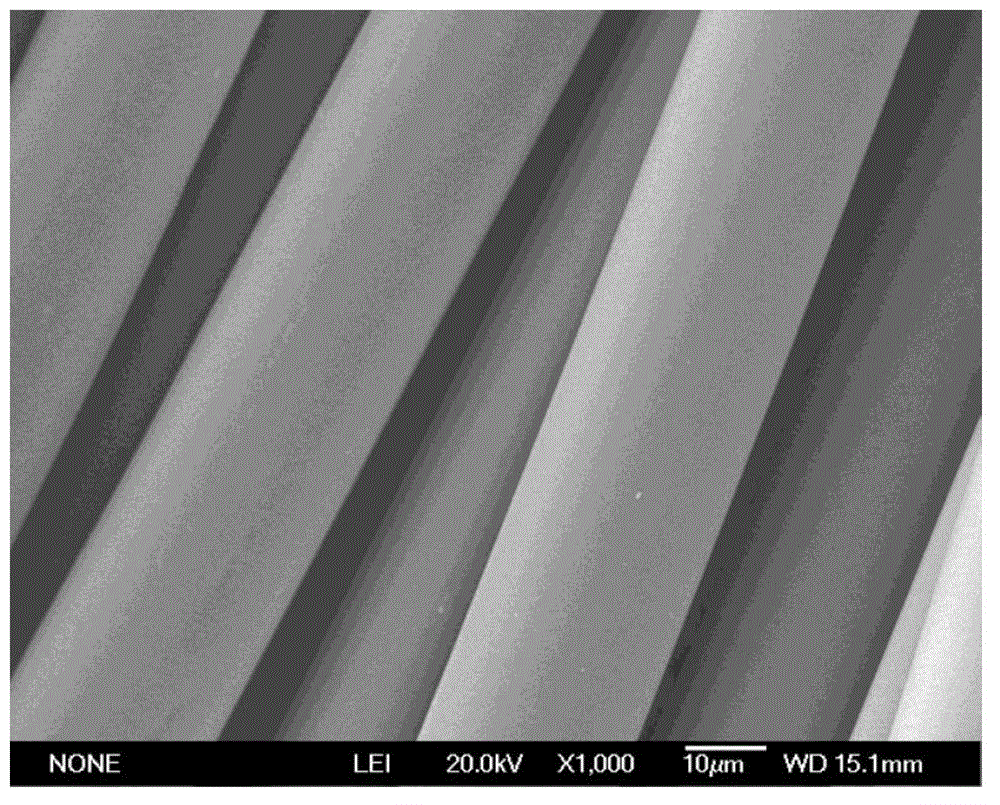

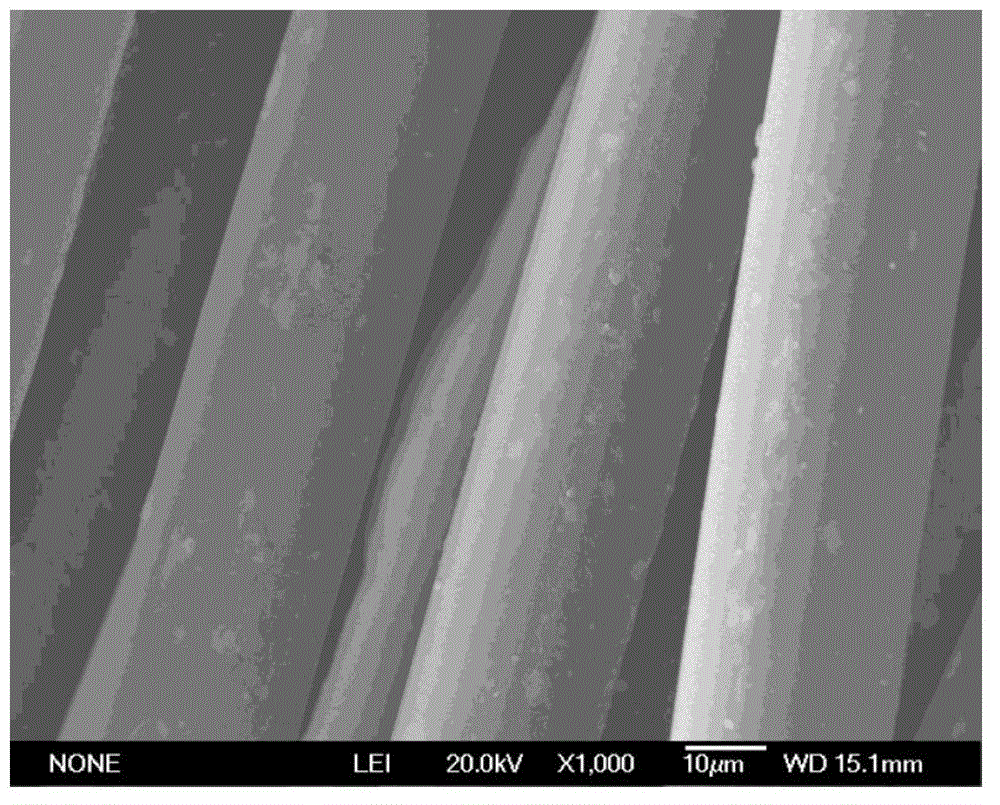

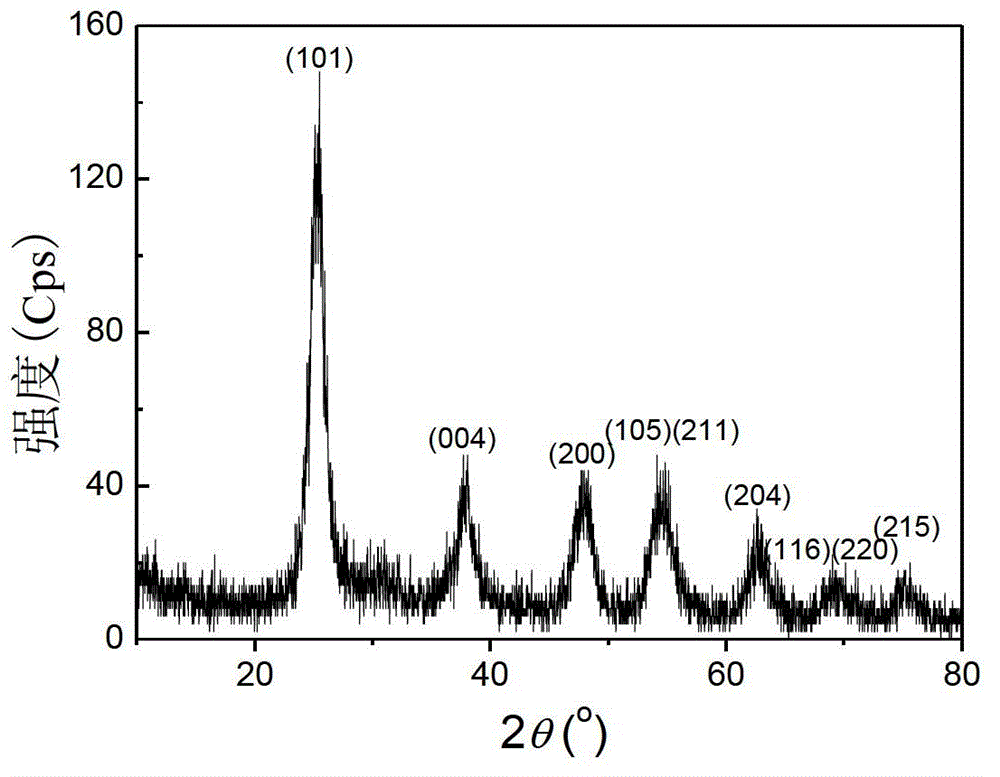

[0063]Prepare a sodium hydroxide solution with a mass concentration of 80g / L, weigh 10g of polyester fiber, soak the polyester fiber in 500mL of sodium hydroxide solution at a bath ratio of 1:50, and treat it at 80°C for 30 minutes. The finished polyester fibers were cleaned with absolute ethanol and deionized water respectively, and dried at 80°C for 20 minutes to dry the pretreated polyester fibers; according to the mass ratio of the etched polyester fibers to tetrabutyl titanate 1 : 1, weigh 10g of tetrabutyl titanate, weigh 1g of silver nitrate according to the mass ratio of the etched polyester fiber to silver nitrate 1:0.1, weigh 0.3% of the mass of the etched polyester fiber, weigh Take 0.03g of disperse blue SE-2R dye, measure the ethanol solution with a mass concentration of 95% according to the volume ratio of the weighed tetrabutyl titanate and the ethanol solution as 1:3, and use the titanate prepared in the previous step The volume ratio of tetrabutyl ester soluti...

Embodiment 2

[0066] Prepare a sodium hydroxide solution with a mass concentration of 120g / L, weigh 10g of polyester fiber, soak the polyester fiber in 800mL of sodium hydroxide solution at a bath ratio of 1:80, and treat it at 100°C for 50 minutes. The finished polyester fibers were washed with absolute ethanol and deionized water respectively, and dried at 100°C for 40 minutes to dry the pretreated polyester fibers; according to the mass ratio of the etched polyester fibers to tetrabutyl titanate 1 : 3, weigh 30g of tetrabutyl titanate, weigh 5g of silver nitrate according to the mass ratio of polyester fiber after etching to silver nitrate 1:0.5, and weigh 2% of the mass of polyester fiber after etching. Take 0.2g of disperse blue BBLS dye, measure the ethanol solution with a mass concentration of 95% according to the volume ratio of the weighed tetrabutyl titanate and ethanol solution as 1:10, and measure the ethanol solution with a mass concentration of 95% according to the tetrabutyl t...

Embodiment 3

[0069] Prepare a sodium hydroxide solution with a mass concentration of 100g / L, weigh 10g of polyester fiber, soak the polyester fiber in 600mL of sodium hydroxide solution at a bath ratio of 1:60, and treat it at 90°C for 40 minutes. The finished polyester fibers were cleaned with absolute ethanol and deionized water respectively, and dried at 90°C for 30 minutes to dry the pretreated polyester fibers; according to the mass ratio of the etched polyester fibers to tetrabutyl titanate 1 : 2, weigh 20g of tetrabutyl titanate, weigh 2g of silver nitrate according to the mass ratio of the etched polyester fiber to silver nitrate 1:0.2, and weigh 1% of the mass of the etched polyester fiber. Take 0.1g of disperse turquoise blue S-GL dye, measure the ethanol solution with a mass concentration of 95% according to the volume ratio of the weighed tetrabutyl titanate and ethanol solution as 1:6, and measure the ethanol solution according to the titanium prepared in the previous step The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com