Glass, and preparation method and application thereof

A glass and sealing glass technology, applied in the field of glass production, can solve the problems of uncontrollable crystallization types, internal collapse, uncontrollable expansion coefficient, etc., to ensure chemical stability and structural stability, and low glass transition temperature. , the effect of improving self-healing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

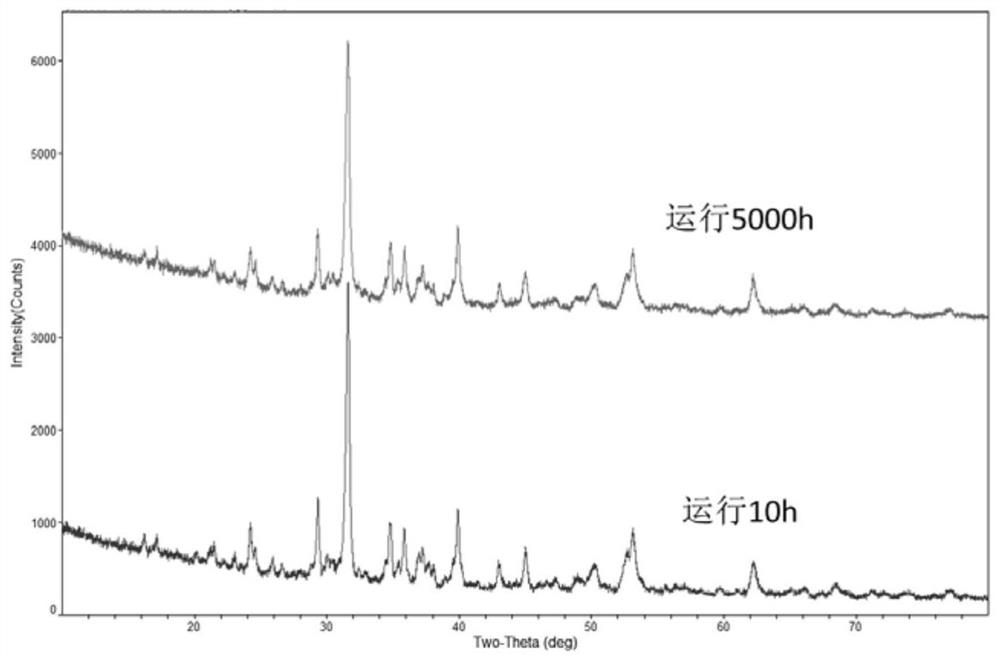

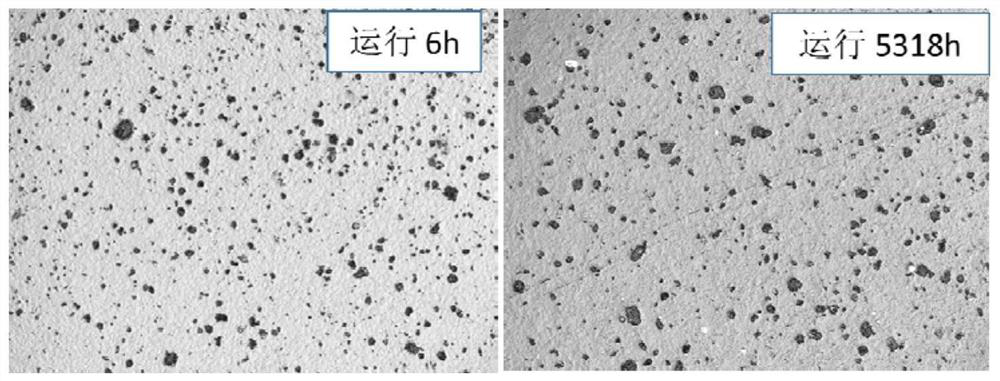

Examples

Embodiment 1

[0033] A kind of glass of the embodiment of the present invention, it is made up of the following components by weight percentage: CaO 40%, MgO 20%, SiO 2 20%, B 2 o 3 10%, ZrO 2 3%, Al 2 o 3 5%, La 2 o 3 2%.

[0034] The preparation method of the glass of the present embodiment specifically comprises the following steps:

[0035] After uniformly mixing the components of the glass in this example, heat and melt at 1250°C, and keep it warm for 0.5 hours to ensure that it is completely clarified without bubbles, then directly quenched in water, crushed and ground to obtain glass (also known as glass powder, the particle size of glass powder is uniform controlled at 1 μm).

[0036] When the glass of this embodiment is used as sealing glass: heat-treat the glass powder at 700° C. for 1 hour during sealing to crystallize the glass powder.

[0037] When the glass of this embodiment is used as a glaze layer glass: when used as a glaze layer, the glass frit is heat-treat...

Embodiment 2

[0039] A kind of glass of the embodiment of the present invention, it is made up of the following components by weight percentage: CaO 30%, MgO 25%, SiO 2 25%, B 2 o 3 15%, ZrO 2 1.5%, Al 2 o 3 1.5%, La 2 o 3 2%.

[0040] The preparation method of the glass of the present embodiment specifically comprises the following steps:

[0041] After uniformly mixing the components of the glass in this example, heat and melt at 1000°C, and keep it warm for 1.0 hour to ensure that it is completely clarified without bubbles, then directly quenched in water, crushed and ground to obtain glass (also known as glass powder, the particle size of which is controlled at 30 μm).

[0042] When the glass of this embodiment is used as sealing glass: heat-treat the glass frit at 800° C. for 10 h during sealing to crystallize the glass.

[0043] When the glass of this embodiment is used as a glaze layer glass: when used as a glaze layer, the glass powder is heat-treated at 870° C. for 15...

Embodiment 3

[0045] A kind of glass of the embodiment of the present invention, it is made up of the following components by weight percentage: CaO 50%, MgO 10%, SiO 2 20%, B 2 o 3 10%, ZrO 2 5%, Al 2 o 3 5%, La 2 o 3 0%.

[0046] The preparation method of the glass of the present embodiment specifically comprises the following steps:

[0047] After uniformly mixing the components of the glass in this example, heat and melt at 1300°C, and keep it warm for 2.0 hours to ensure that it is completely clarified without bubbles, then directly quenched in water, crushed and ground to obtain glass (also known as glass powder, the particle size of which is controlled at 10 μm).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com