Method for preparing graphene on silicon base without metal catalyst

A catalyst and graphene technology, applied in metal material coating process, gaseous chemical plating, vacuum evaporation plating, etc., can solve the problems of graphene quality instability, unfavorable large-scale production, high cost of metal materials, etc., to achieve good results Effects of thermal and chemical stability, uniform lattice orientation, and good crystallization quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

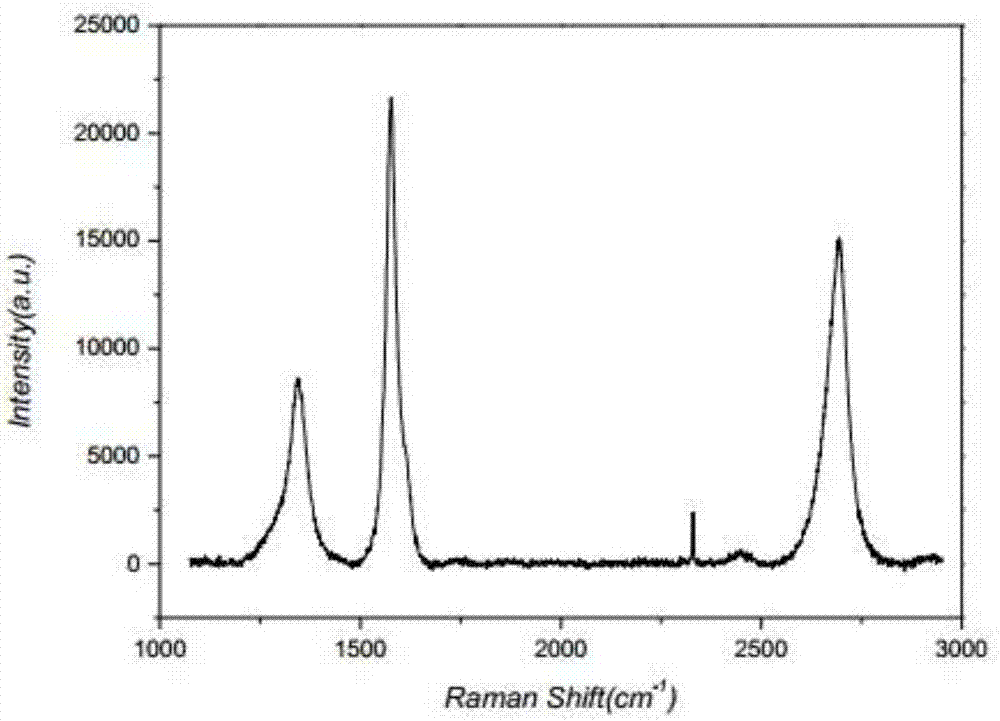

Image

Examples

Embodiment 1

[0056] The present invention adopts radio frequency magnetron sputtering technology and chemical vapor deposition method, uses hexagonal boron nitride target as magnetron sputtering target material, and uses silicon base with crystal orientation of 300nm silicon dioxide as sputtering substrate .

[0057] (1) Pump the background air pressure in the sputtering chamber to 6×10 -4 Below Pa, feed nitrogen: argon = 6:24 (unit: sccm);

[0058] (2) After adjusting the glow, pre-sputter for 30 minutes;

[0059] (3) Raise the temperature of the substrate to 500°C, adjust the sputtering pressure to 0.5Pa, and adjust the sputtering power to 100W;

[0060] (4) The sputtering time is 30min, and the boron-nitrogen film thickness is 280nm at this moment;

[0061] (5) Take out the sample after cooling down to room temperature;

[0062] (6) annealing at 600°C for 2 hours in a vacuum tube resistance furnace in an argon atmosphere;

[0063] (7) Vacuumize to 20Pa in the vacuum tube type resi...

Embodiment 2

[0068] The present invention adopts radio frequency magnetron sputtering technology and chemical vapor deposition method, uses hexagonal boron nitride target as magnetron sputtering target material, and uses silicon substrate with crystal direction of 200nm silicon dioxide as sputtering substrate .

[0069] (1) Pump the background air pressure in the sputtering chamber to 6×10 -4 Below Pa, feed nitrogen: argon = 8:32 (unit: sccm);

[0070] (2) After adjusting the glow, pre-sputter for 40 minutes;

[0071] (3) Raise the temperature of the substrate to 500°C, adjust the sputtering pressure to 0.5Pa, and adjust the sputtering power to 100W;

[0072] (4) The sputtering time is 30min, and the boron-nitrogen film thickness is 280nm at this moment;

[0073] (5) Take out the sample after cooling down to room temperature;

[0074] (6) annealing at 600°C for 3 hours in a vacuum tube resistance furnace in an argon atmosphere;

[0075] (7) Vacuumize to 20Pa in the vacuum tube type r...

Embodiment 3

[0080] The present invention adopts radio frequency magnetron sputtering technology and chemical vapor deposition method, uses hexagonal boron nitride target as magnetron sputtering target material, and uses silicon substrate with crystal direction of 300nm silicon dioxide as sputtering substrate .

[0081] (1) Pump the background air pressure in the sputtering chamber to 6×10 -4 Below Pa, feed nitrogen: argon = 5:20 (unit: sccm);

[0082] (2) After adjusting the glow, pre-sputter for 60 minutes;

[0083] (3) Raise the temperature of the substrate to 500°C, adjust the sputtering pressure to 0.5Pa, and adjust the sputtering power to 100W;

[0084] (4) The sputtering time is 30min, and the boron-nitrogen film thickness is 280nm at this moment;

[0085] (5) Take out the sample after cooling down to room temperature;

[0086] (6) annealing at 600°C for 3 hours in a vacuum tube resistance furnace in an argon atmosphere;

[0087] (7) Vacuumize to 20Pa in the vacuum tube type r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com