ZSM-5 molecular sieve and preparation method and application thereof

A technology of ZSM-5 and molecular sieves, which is applied in chemical instruments and methods, other chemical processes, crystalline aluminosilicate zeolites, etc., can solve the difficulties in the separation of solid silicon sources, the unstable crystal form of products, and the long time required for crystallization and other problems, to achieve the effect of simple preparation process, energy utilization rate, green environmental protection, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

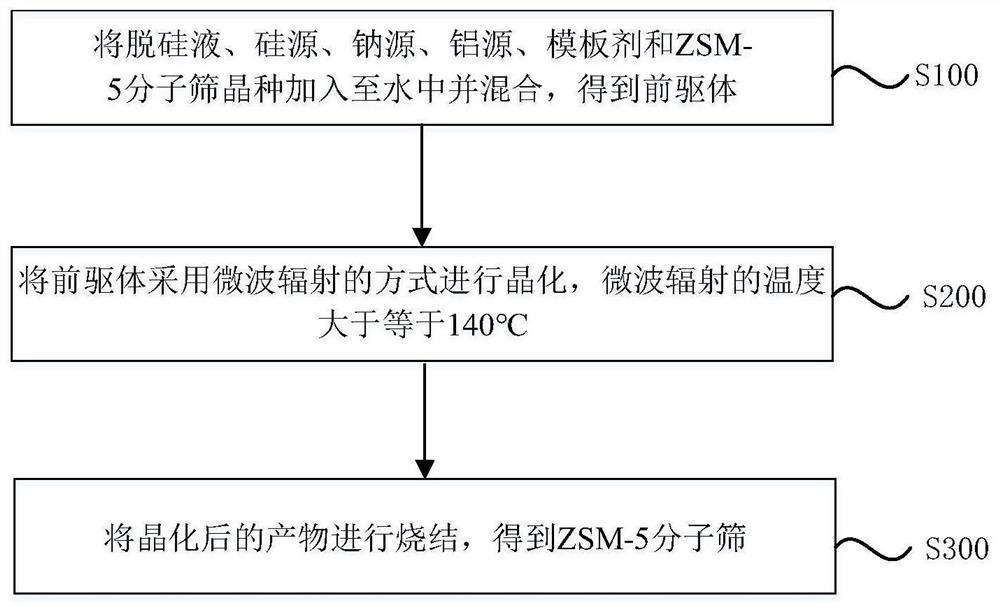

preparation example Construction

[0080] In some embodiments, after S200 and before S300, the preparation method further includes the steps of filtering, washing and drying the crystallized product in sequence.

[0081] In some embodiments, in the step of washing the crystallized product, the product is washed until the product is neutral and then dried.

[0082]In some embodiments, in the step of drying the crystallized product, the drying temperature is 80-120° C., and the drying time is 6-24 hours.

[0083] S300, sintering the crystallized product to obtain a ZSM-5 molecular sieve.

[0084] In some embodiments, the sintering temperature in step (2) is 400-600°C.

[0085] In some embodiments, the sintering time in step (2) is 4-8 hours.

[0086] In some embodiments, after S300, the preparation method further includes the following steps:

[0087] The ZSM-5 molecular sieve is pressed into tablets, ground and sieved to obtain a ZSM-5 molecular sieve of 40-60 mesh.

[0088] Yet another embodiment provides t...

Embodiment 1

[0092] This embodiment provides a kind of ZSM-5 molecular sieve and preparation method thereof, the preparation method of described ZSM-5 molecular sieve comprises the following steps:

[0093] (1) Measure 25mL of concentrated desiliconization solution, add 10.8g of silica sol to it, stir evenly, add 0.368g of sodium hydroxide and 3.5g of n-butylamine as a silicon solution, and then weigh 0.34g of Al 2 (SO 4 ) 3 18H 2 O, add water and stir to dissolve, as an aluminum solution, add the aluminum solution dropwise to the silicon solution, stir evenly, add 0.29g ZSM-5 molecular sieve seed crystals to obtain a precursor;

[0094] The molar ratio of each substance in the precursor is SiO 2 :Al 2 o 3 :Water:Na 2 O: n-butylamine=1:0.005:30:0.2:0.4, the quality of ZSM-5 molecular sieve seed crystal is 4% of the quality of ZSM-5 molecular sieve;

[0095] (2) After stirring the above precursor for 0.5h, transfer it to the reaction kettle and crystallize it in a microwave reactor a...

Embodiment 2

[0099] This embodiment provides a kind of ZSM-5 molecular sieve and preparation method thereof, the preparation method of described ZSM-5 molecular sieve comprises the following steps:

[0100] (1) Measure 25mL of concentrated desiliconization solution, add 10.8g of silica sol to it, stir evenly, add 0.368g of sodium hydroxide and 3.5g of n-butylamine as a silicon solution, and then weigh 0.20g of Al 2 (SO 4 ) 3 18H 2 O, add water and stir to dissolve, as an aluminum solution, add the aluminum solution dropwise to the silicon solution, stir evenly, add 0.29g ZSM-5 molecular sieve seed crystals to obtain a precursor;

[0101] The molar ratio of each substance in the precursor is SiO 2 :Al 2 o 3 :Water:Na 2 O: n-butylamine=1:0.003:30:0.2:0.4, the quality of ZSM-5 molecular sieve seed crystal is 4% of the quality of ZSM-5 molecular sieve;

[0102] (2) After stirring the above precursor for 0.5h, transfer it to the reaction kettle and crystallize it in a microwave reactor a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com