Silicate-based fluorescent material and synthetic method thereof

A fluorescent material and silicate technology, applied in the field of fluorescent materials and their synthesis, can solve the problems of luminous color change, lower luminous intensity, blue shift of emission spectrum, etc., achieve high luminous efficiency, increase luminous intensity, and good chemical stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

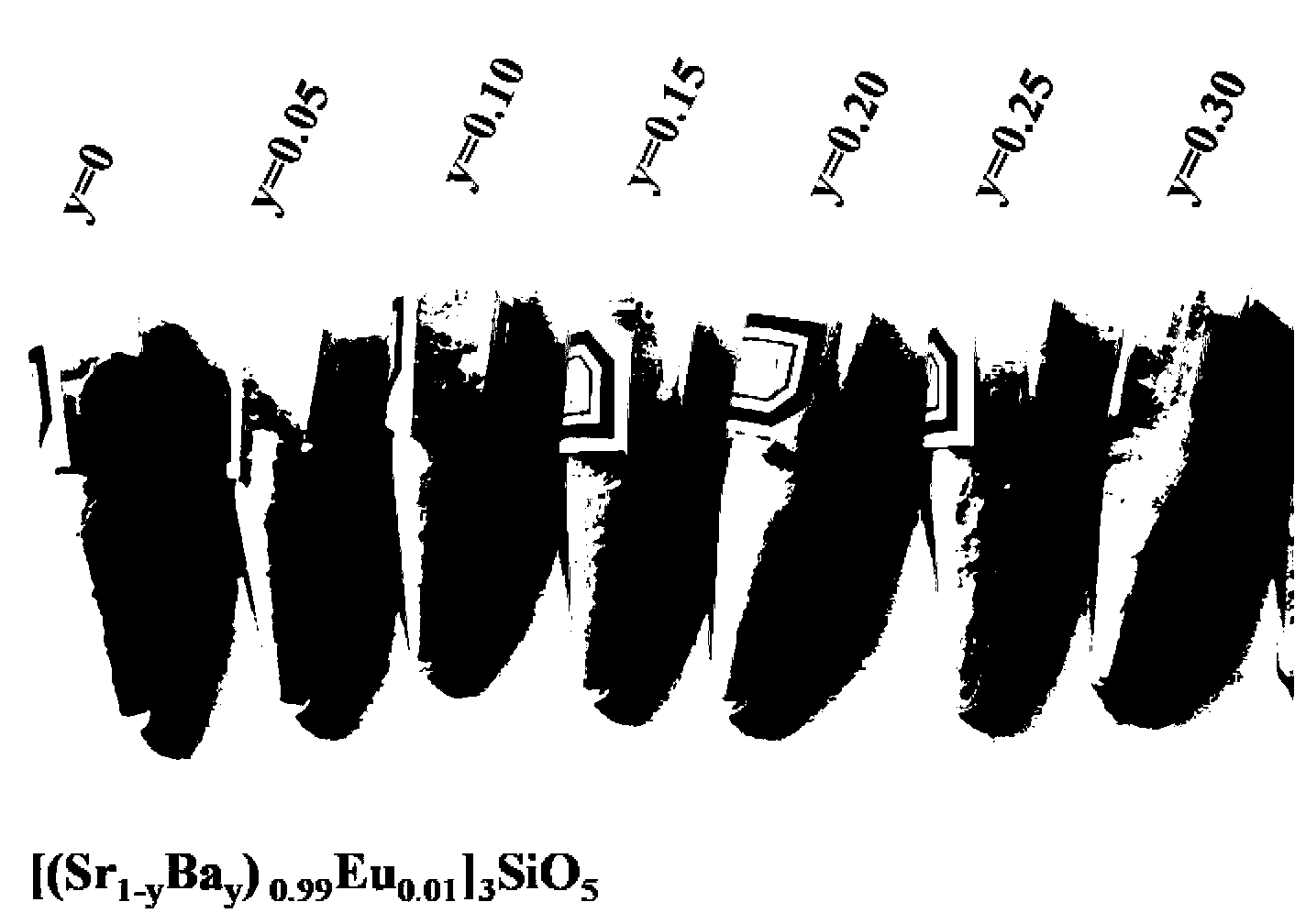

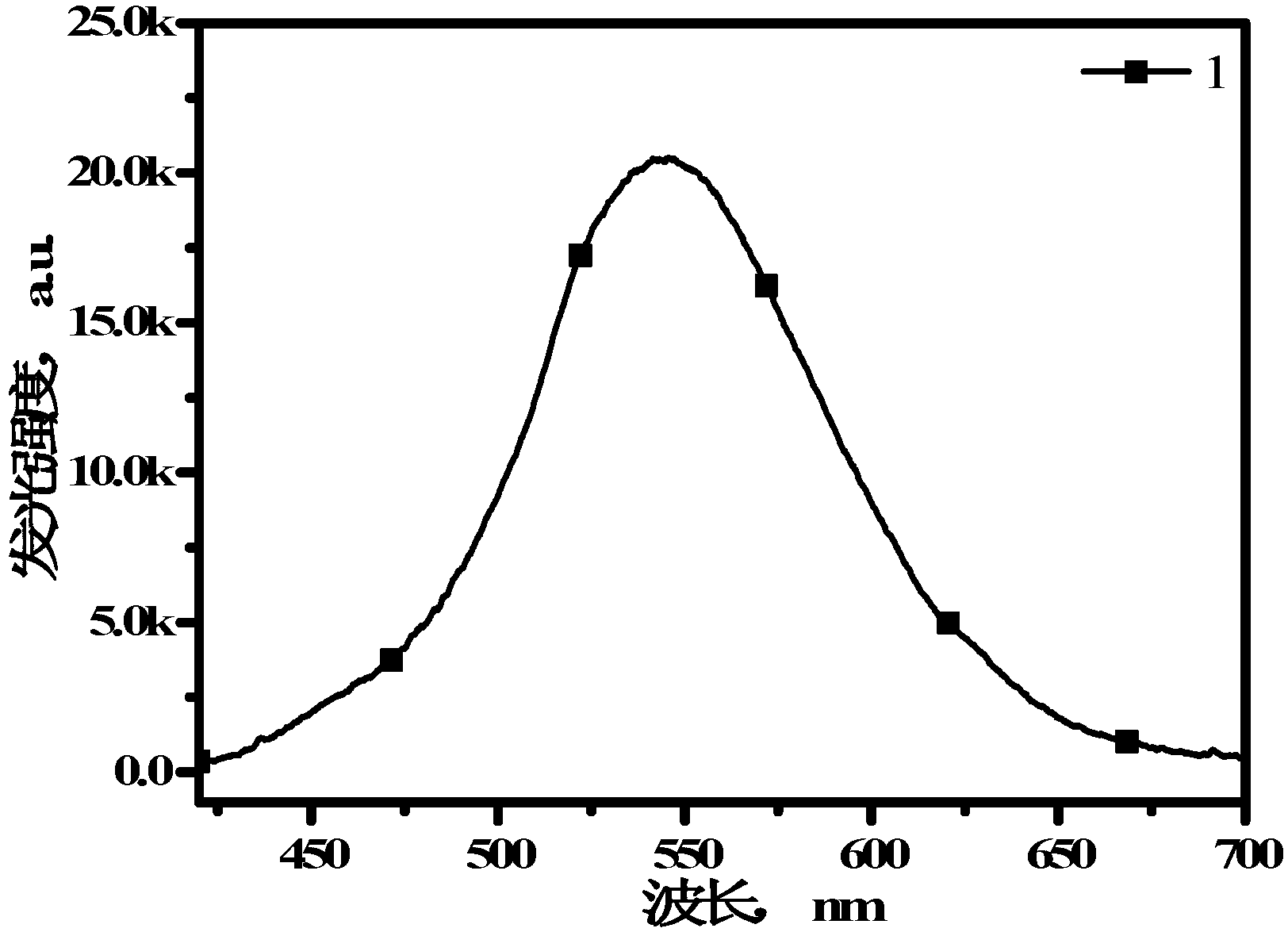

[0046] The chemical formula of the fluorescent material in this embodiment is (Sr 0.99 Eu 0.01 ) 3 SiO 5 .

[0047] In this example, SrCO3 , SiO 2 and Eu 2 o 3 Raw materials, where SiO 2 It is a conventional micron powder. After being fully ground, put the mixed product into a corundum crucible, cover it and put it into a tube furnace, tighten the flange, and then pass H into the furnace. 2 / N 2 =5 / 95 reducing gas. The high-temperature furnace sintering system is as follows: firstly, the temperature is raised from room temperature to 600°C at 5°C / min, then the temperature is raised to 900°C at 4°C / min, and then the temperature is raised to 1300°C at 3°C / min. Cool down to 900°C at 4°C / min, then cool down to 600°C at 5°C / min, turn off the power, cool the sample to room temperature with the furnace, and finally turn off the reducing gas. After the samples were released from the furnace, they were ground and pulverized, and the emission spectrum and crystal structure of ...

Embodiment 2

[0049] The general chemical formula of the synthesized substance in this embodiment is (Sr 0.99 Eu 0.01 ) 3 SiO 5 .

[0050] This embodiment synthesizes five samples, wherein nano-SiO 2 The percentages of the total mass of silicon source materials are 0, 10%, 30%, 50% and 70%, respectively. According to the sample composition ratio shown in Table 1, the raw material SrCO 3 , nano-SiO 2 , conventional SiO 2 Micropowder and Eu 2 o 3 , then fully grind various raw materials, put the mixed product into a corundum crucible, and burn it at 1000°C for 2 hours in the atmosphere, grind the sample again after it comes out of the furnace, and then put the sample into the corundum crucible, cover it into a tube furnace at H 2 / N 2 Calcination at 1400°C for 4 hours under a reducing atmosphere of =25 / 75, until the furnace temperature is cooled to room temperature and the reducing gas is turned off. After the samples come out of the furnace, they are ground and pulverized, classif...

Embodiment 3

[0055] The general chemical formula of the synthesized substance in this embodiment is (Sr 0.99 Eu 0.01 ) 3 SiO 5 .

[0056] The preparation method of the present embodiment is the same as embodiment 2, and the difference is that in H 2 / N 2 Calcination at 1450°C for 4 hours under a reducing atmosphere of =25 / 75. The emission spectrum of the synthesized sample in this embodiment is as follows: Figure 4 shown. The luminous intensity of the sample varies with the nano-SiO 2 The luminescence intensity of the sample with the doping amount of 10% has been significantly improved compared with that of the undoped sample; when the SiO 2 When the dosage is 30%, the luminous intensity reaches the maximum, and its luminous intensity is 161% of the undoped sample; when nano-SiO 2 When the content increased to 50%, the luminous intensity decreased slightly; the luminous intensity of the two samples with doping amount of 50% and 70% was almost the same. This practice synthesizes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com