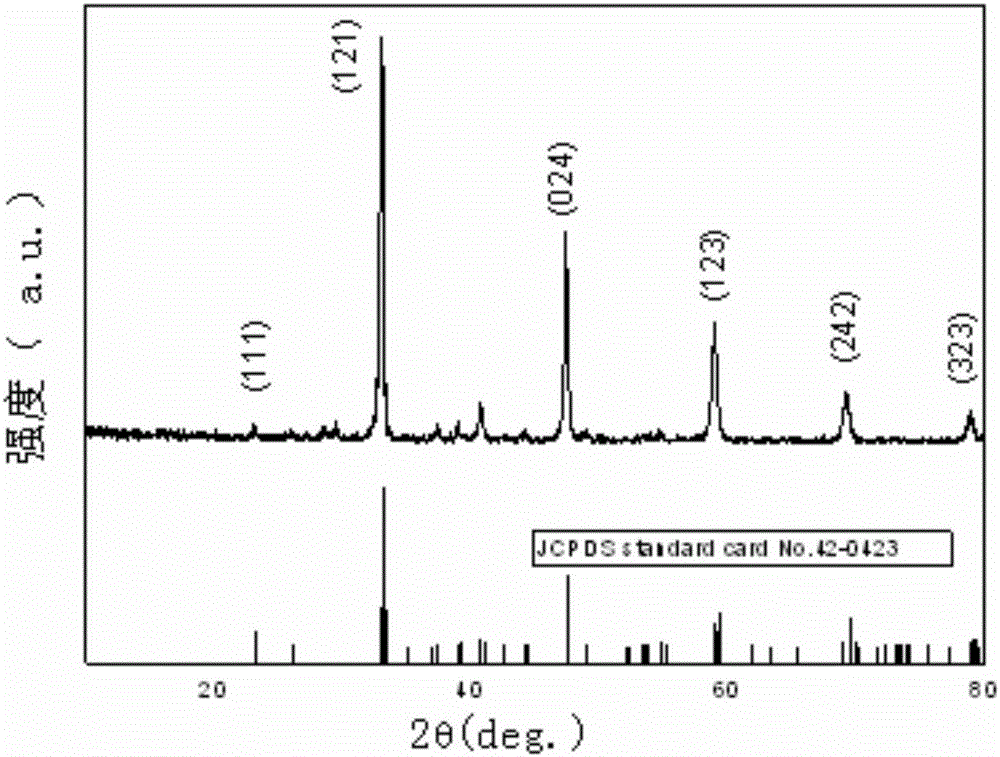

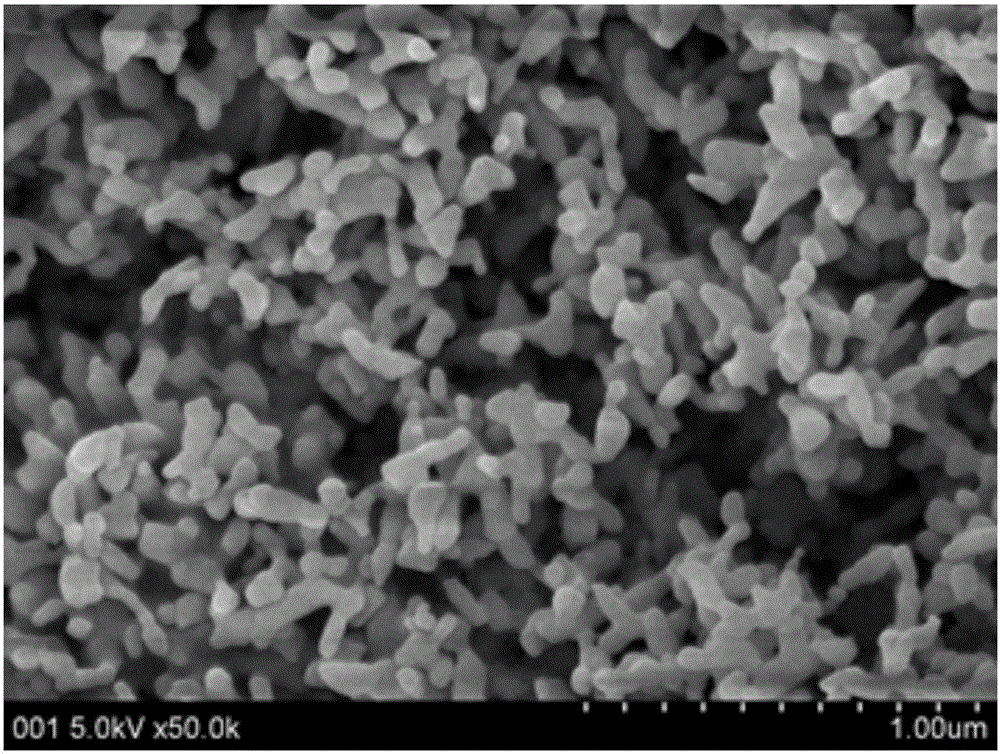

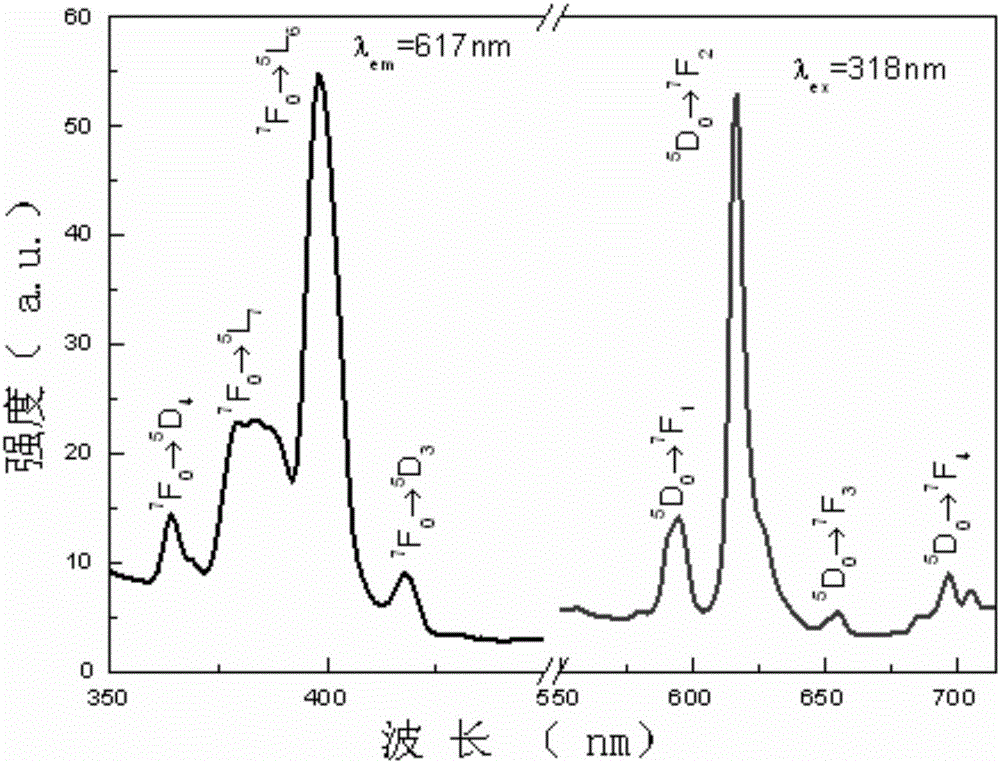

(SrxCay)0.97TiO3:Eu3+0.03 fluorescent powder and preparing method thereof

A phosphor and solution technology, applied in chemical instruments and methods, luminescent materials, etc., can solve problems such as unfavorable mass production, inability to observe the reaction process in hydrothermal synthesis, and poor experimental repeatability, and achieve improved luminous intensity, crystallinity, etc. Small particle size and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 0.3152g of oxalic acid dihydrate and dissolve it in 10ml of absolute ethanol to obtain a clear solution A, weigh 0.3523g of ammonium oxalate and dissolve it in 70ml of deionized water to obtain a clear solution B, dissolve 1ml of tetrabutyl titanate in 10ml of To obtain a clear solution C in absolute ethanol, weigh 0.5048g of calcium nitrate tetrahydrate, 0.0503g of strontium nitrate, and 0.0388g of europium nitrate hexahydrate, and dissolve them in 50ml of deionized water to obtain a clear solution D; put solutions A and B drop by drop in order Add solution C, and control the pH between 2.5-3, stir continuously to obtain clear solution E, add D dropwise to E, control the magneton speed to 2400rpm, stir and react for 2 hours, the obtained precipitate; Wash twice with water, once with 5mol / L hydrochloric acid, and once with absolute ethanol; the speed of centrifugation is 5000r / min, and the time is controlled at 5min; dry for 12h to obtain the precipitated product. ...

Embodiment 2

[0027] Weigh 0.3152g of oxalic acid dihydrate and dissolve it in 10ml of absolute ethanol to obtain a clear solution A, weigh 0.3523g of ammonium oxalate and dissolve it in 70ml of deionized water to obtain a clear solution B, dissolve 1ml of tetrabutyl titanate in 10ml of To obtain a clear solution C in absolute ethanol, weigh 0.3926g of calcium nitrate tetrahydrate, 0.1509g of strontium nitrate, and 0.0388g of europium nitrate hexahydrate, and dissolve them in 50ml of deionized water to obtain a clear solution D; put solutions A and B drop by drop in order Add solution C, and control the pH between 2.5-3, stir continuously to obtain clear solution E, add D dropwise to E, control the magneton speed to 2400rpm, stir and react for 2 hours, the obtained precipitate; Wash twice with water, once with 5mol / L hydrochloric acid, and once with absolute ethanol; the speed of centrifugation is 5000r / min, and the time is controlled at 5min; dry for 12h to obtain the precipitated product. ...

Embodiment 3

[0029] Weigh 0.3152g of oxalic acid dihydrate and dissolve it in 10ml of absolute ethanol to obtain a clear solution A, weigh 0.3523g of ammonium oxalate and dissolve it in 70ml of deionized water to obtain a clear solution B, dissolve 1ml of tetrabutyl titanate in 10ml of To obtain a clear solution C in absolute ethanol, weigh 0.5048g of calcium nitrate tetrahydrate, 0.0503g of strontium nitrate, and 0.0388g of europium nitrate hexahydrate, and dissolve them in 50ml of deionized water to obtain a clear solution D; put solutions A and B drop by drop in order Add solution C, and control the pH between 2.5-3, stir continuously to obtain clear solution E, add D dropwise to E, control the magneton speed to 2400rpm, stir and react for 2 hours, the obtained precipitate; Wash twice with water, once with 5mol / L hydrochloric acid, and once with absolute ethanol; the speed of centrifugation is 5000r / min, and the time is controlled at 5min; dry for 12h to obtain the precipitated product. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com