Preparation of fluorine and carbon co-doped nano-titanium dioxide visible light photocatalyst

A nano-titanium dioxide, photocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as the inability to guarantee photocatalytic performance, and achieve easy industrial production, mild reaction conditions, raw materials easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

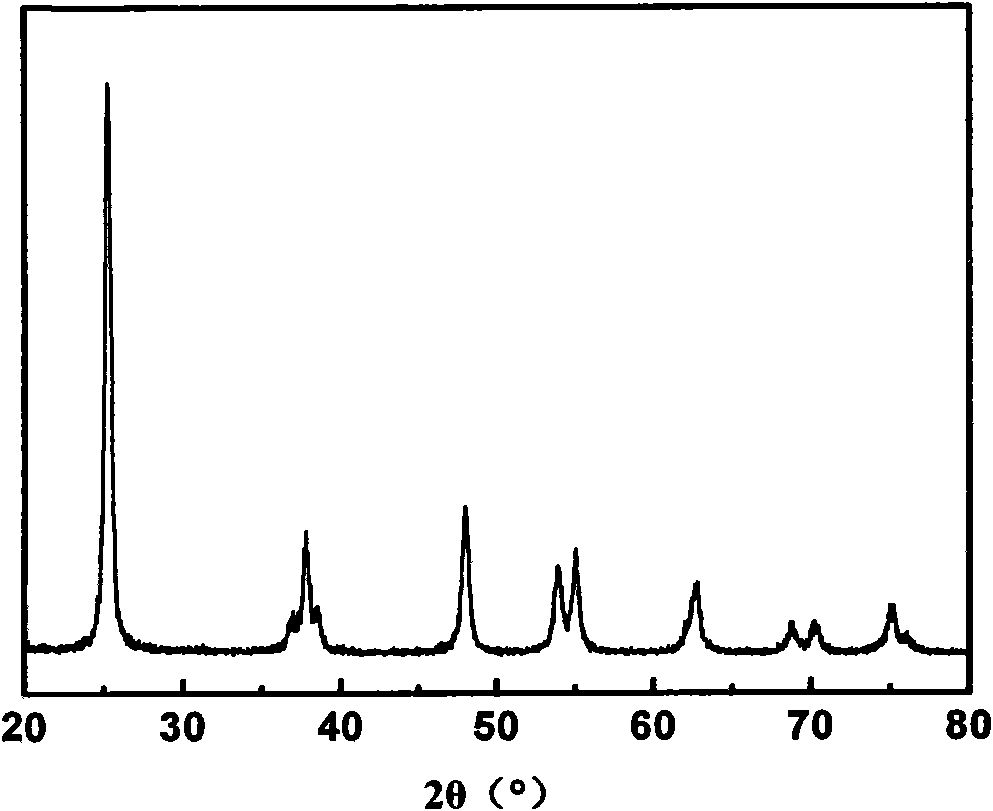

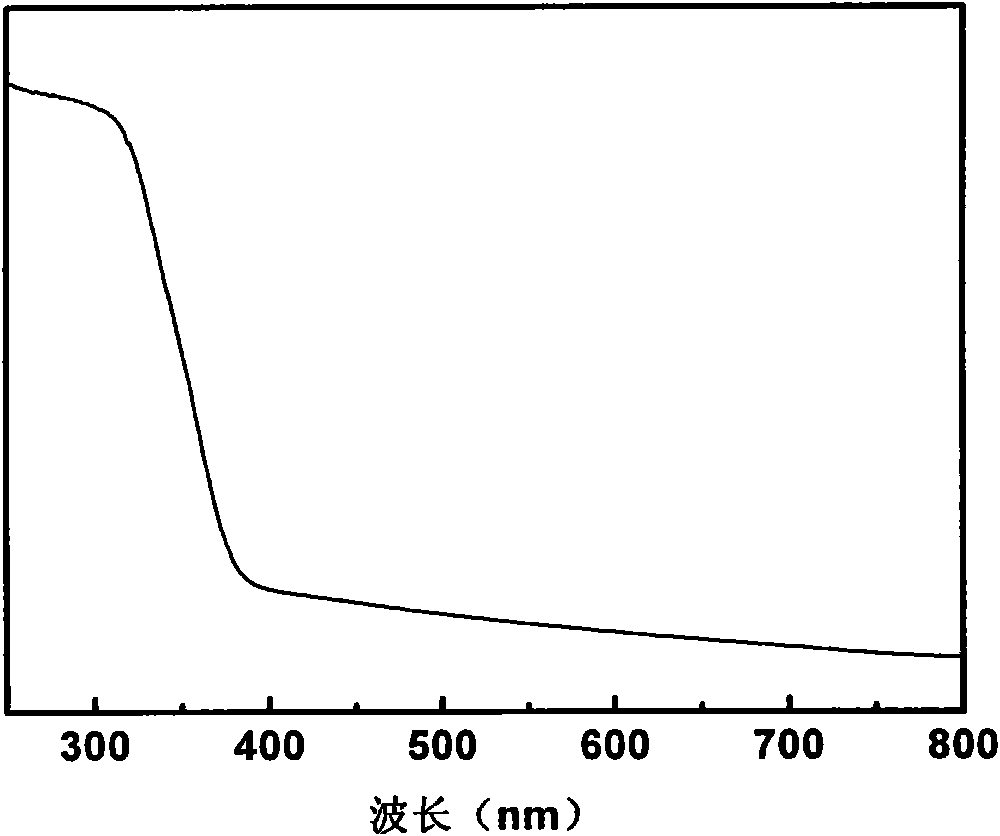

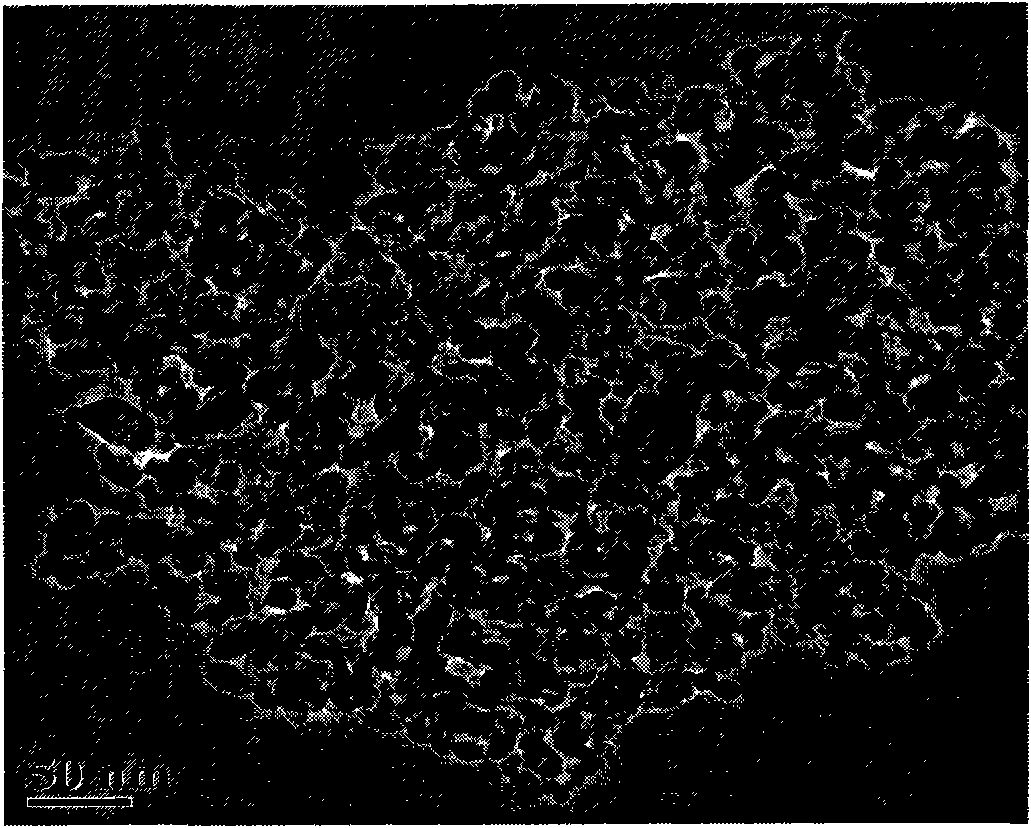

[0024] Measure 100mL of 0.05M ammonium fluoride solution and 1mL of ethylenediamine with a content greater than 99wt% in the reactor. Measure 100mL of 1M tetrabutyl titanate solution in absolute ethanol in the dropping funnel, and add the solution of tetrabutyl titanate in absolute ethanol dropwise to the aqueous solution of ammonium fluoride and ethylenediamine under stirring at room temperature. White precipitate. After the dropwise addition was completed, the solution was stirred at room temperature for 12 hours to further hydrolyze the tetrabutyl titanate to obtain a sol. Then the sol was dried at 80°C for 12 hours, and the water and ethanol were evaporated to obtain a pale yellow gel. Calcined at 400°C for 2 hours to obtain light gray powdery titanium dioxide co-doped with fluorine and carbon. figure 1 It is the X-ray diffraction pattern of fluorine and carbon co-doped titanium dioxide synthesized in this example, and the diffraction peaks in the figure indicate that t...

Embodiment 2

[0026] Measure 100 mL of 0.1 M ammonium fluoride solution and 1 mL of ethylenediamine with a content greater than 99 wt % in the reactor. Measure 100mL of 1M tetrabutyl titanate solution in absolute ethanol in the dropping funnel, and add the solution of tetrabutyl titanate in absolute ethanol dropwise to ammonium fluoride and ethylenediamine aqueous solution under stirring at room temperature. White precipitate. After the dropwise addition, the solution was stirred at room temperature for 10 hours to further hydrolyze the tetrabutyl titanate to obtain a sol. Then the sol was dried at 100°C for 10 hours, and the water and ethanol were evaporated to obtain a pale yellow gel. Calcined at 400°C for 2 hours to obtain a light gray powdery fluorine-carbon co-doped nano-titanium dioxide photocatalyst.

Embodiment 3

[0028] Measure 100mL of 0.05M ammonium fluoride solution and 2mL of ethylenediamine with a content greater than 99wt% in the reactor. Measure 100mL of 1M tetrabutyl titanate solution in absolute ethanol in the dropping funnel, under stirring at room temperature, add the solution of tetrabutyl titanate in absolute ethanol dropwise to ammonium fluoride and ethylenediamine In aqueous solution, a white precipitate appeared. After the dropwise addition, the solution was stirred at room temperature for 8 hours to further hydrolyze the tetrabutyl titanate to obtain a sol. Then the sol was dried at 100°C for 10 hours, and the water and ethanol were evaporated to obtain a pale yellow gel. Calcined at 400° C. for 2 hours to obtain a light brown powdery fluorine-carbon co-doped nano-titanium dioxide photocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com