Cerium dioxide-based composite catalyst, and preparation method and application thereof

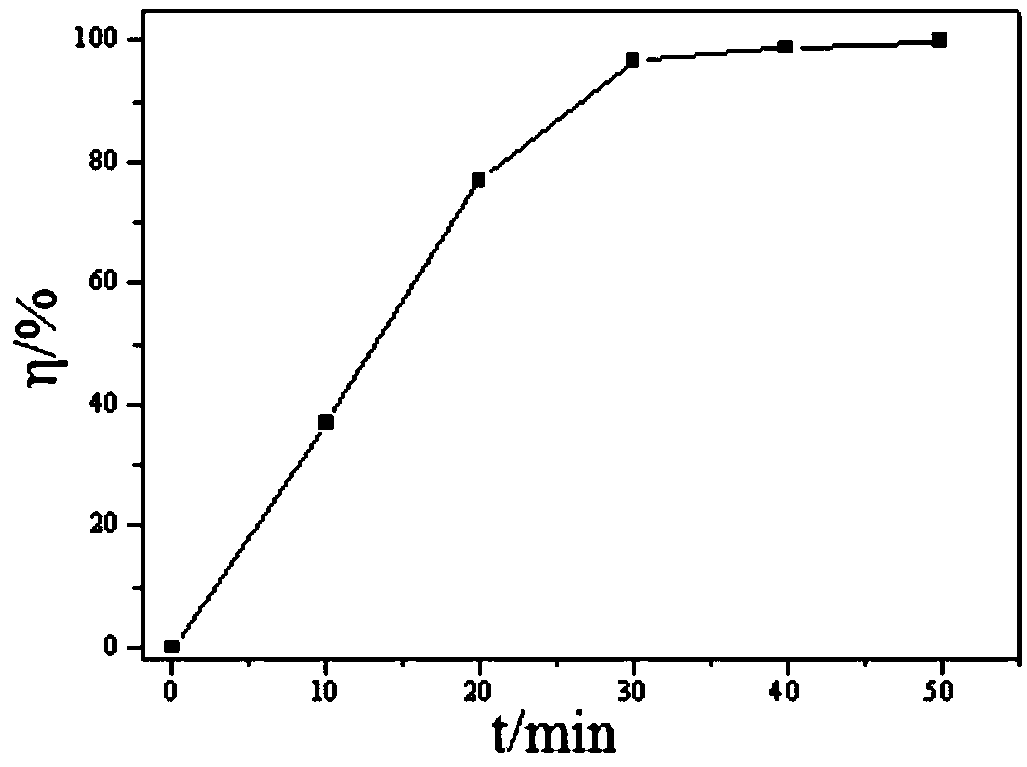

A technology of composite catalyst and ceria, which is applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problems of low catalytic efficiency and high cost, and achieve particle Uniform size, low cost, good catalytic degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

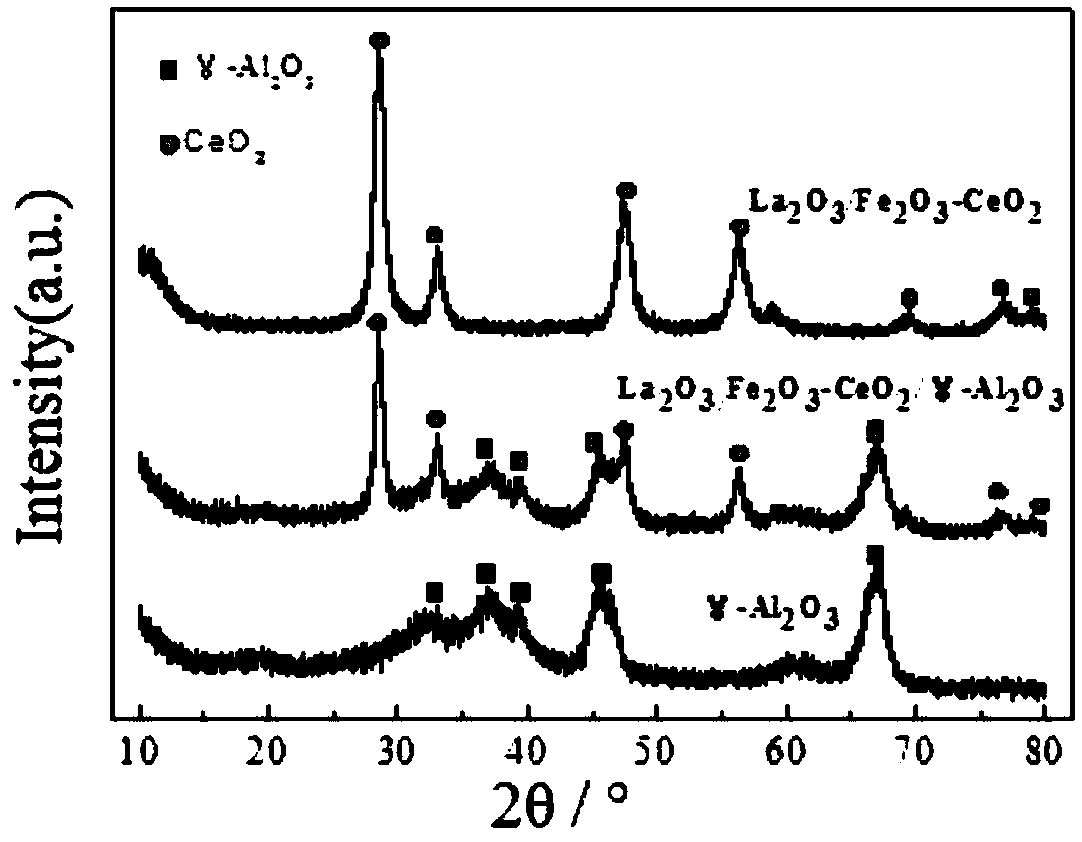

[0030] 1. Co-precipitation method to prepare ceria-based composite catalyst active component La 2 o 3 / Fe 2 o 3 -CeO 2

[0031] Dissolve 0.868g of cerium nitrate hexahydrate, 0.013g of lanthanum nitrate and 0.024g of ferric nitrate in 100mL of deionized water and mix evenly, then slowly add the solution into a 250mL three-necked bottle, heat water at 80°C, and mechanically stir at a speed of 350rpm. Add 1.0 mol / L ammonium bicarbonate solution dropwise at mL / min, control the end point pH of the reaction solution to be about 10.0, and continue heating and stirring for 0.5 h. After cooling to room temperature, the red precipitate was obtained by centrifugal filtration, and washed with deionized water until neutral, and the obtained precipitate was dried in an oven at 80°C for 10 hours to obtain a precursor, which was then roasted in a muffle furnace at 550°C for 4 hours. ceria-based composite catalyst active component La 2 o 3 / Fe 2 o 3 -CeO 2 ;

[0032] 2. Ceria-based...

Embodiment 2

[0038] All the other are the same as embodiment 1, change the doping amount of lanthanum nitrate and ferric nitrate, the add-on of lanthanum nitrate and ferric nitrate is changed by 0.008g, 0.016g, 0.04g, 0.056g and 0.08g respectively.

Embodiment 3

[0040] All the other are the same as embodiment 1, change La 2 o 3 / Fe 2 o 3 -CeO 2 Relative to γ-Al 2 o 3 content, La 2 o 3 / Fe 2 o 3 -CeO 2 The amount of the added amount was changed by 0.06g, 0.14g and 0.2g respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com