Collosol-coating preparation method of lithium iron phosphate being the positive electrode material of lithium ion battery

A lithium iron phosphate, lithium ion battery technology, applied in electrode manufacturing, battery electrodes, chemical instruments and methods, etc., can solve the problem of low electronic conductivity and ionic conductivity, high requirements for precursor manufacturing equipment, and high rate charge and discharge Poor performance and other problems, to achieve stable electrochemical performance, avoid uneven mixing problems, and stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

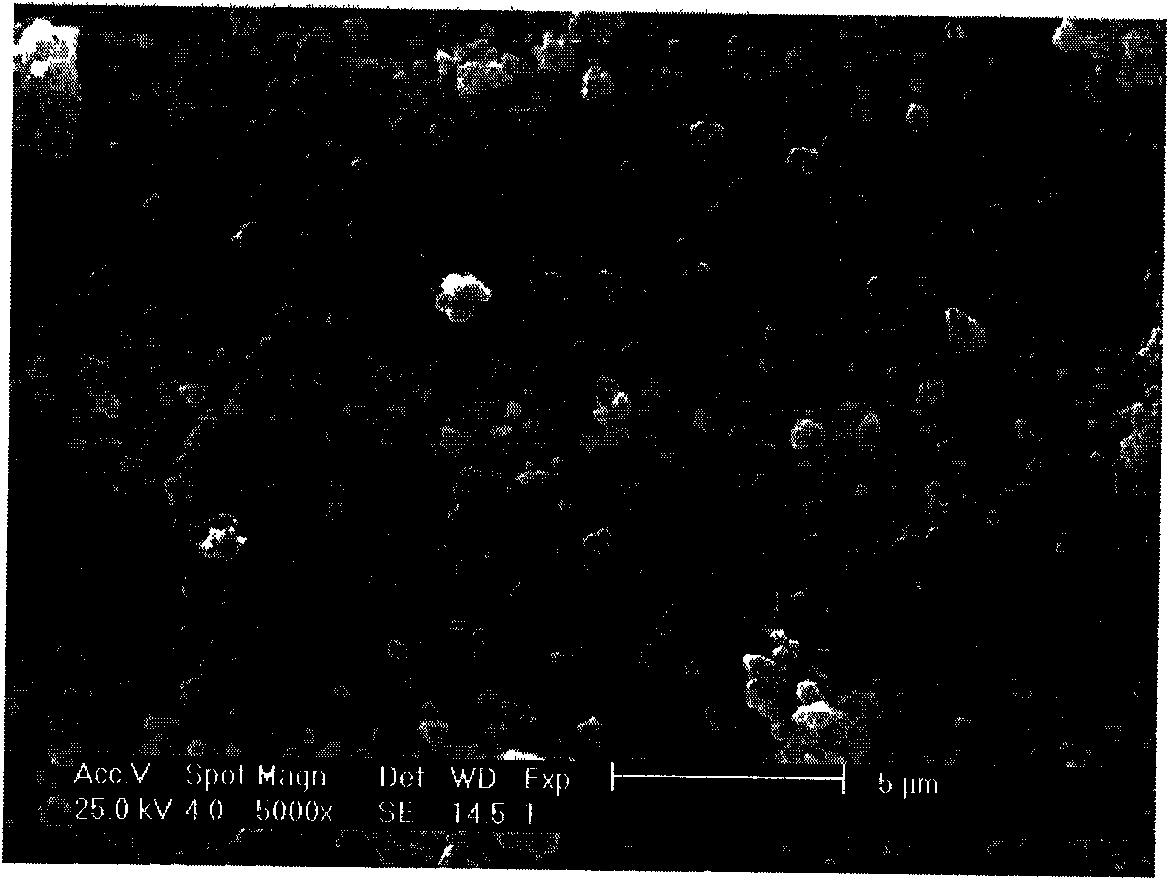

[0033] Lithium-ion battery cathode material lithium iron phosphate sol coating preparation method: first disperse 3Gg of natural plant starch in 97g of distilled water, then mix iron acetate, lithium hydroxide, and ammonium dihydrogen phosphate in accordance with the stoichiometric ratio 20g into the starch suspension Cloudy liquid. High-speed shear liquid phase dispersion was used for 0.5 hours. Then, it is pulverized by a colloid mill, so that the particle size of the solid powder is further ground to below 1 micron. Put the dispersed liquid into the reaction kettle, slowly raise the temperature to 85°C under stirring, and keep the temperature constant for 5 hours to form a high-viscosity gel-like solution in which the solid powder is uniformly dispersed. Pass the gel suspension into the casting machine and coat it into a slurry layer with a thickness of 1mm. The slurry layer is dried in the drying channel at 80°C for about 1 hour, and the solid powder is densely settled to...

Embodiment 2

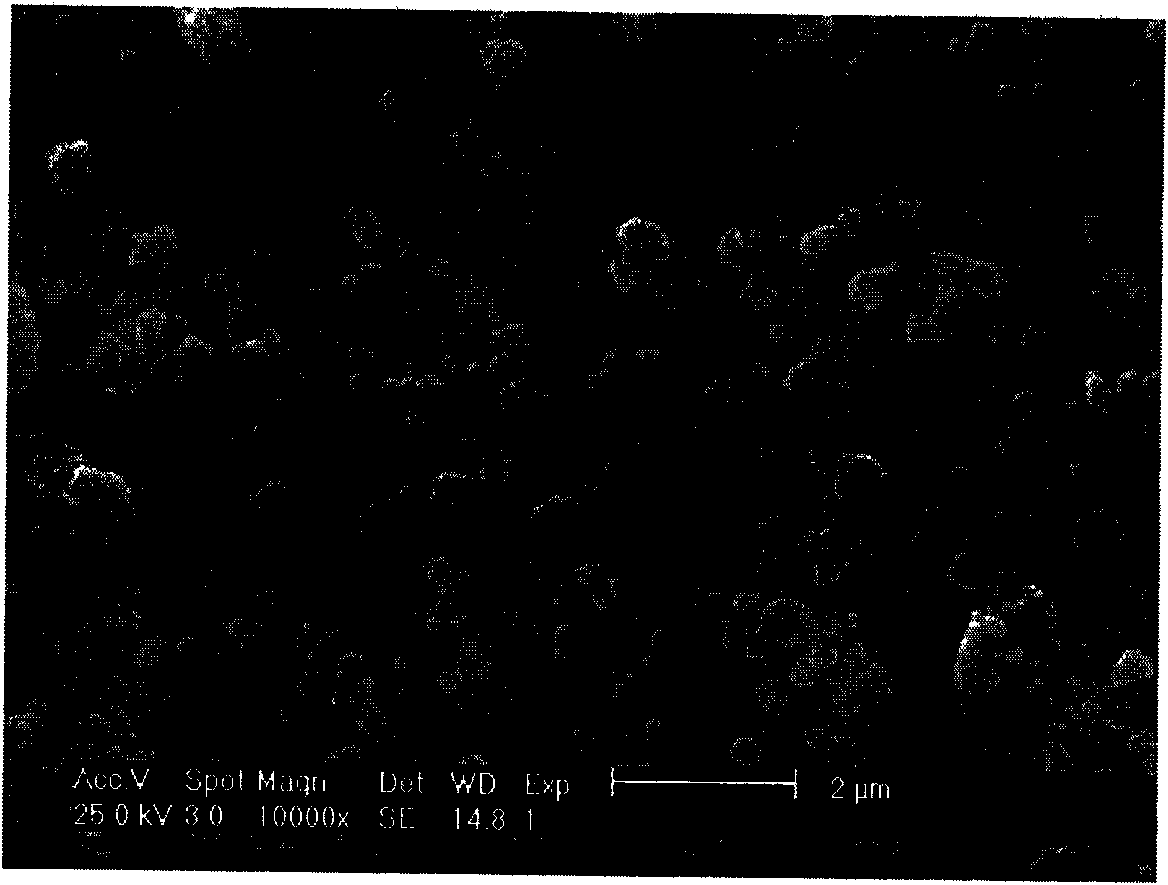

[0036]Lithium-ion battery cathode material lithium iron phosphate sol coating preparation method: first disperse 10g of soluble starch in 90g of distilled water, then mix 100g of ferric nitrate, lithium carbonate, and ammonium hydrogen phosphate in accordance with the stoichiometric ratio into the prepared liquid . Use a high-speed shear disperser to disperse for 1 hour. Then, it is pulverized by a colloid mill, so that the particle size of the solid powder is further ground to below 1 micron. Put the dispersed liquid into the reaction kettle, slowly raise the temperature to 100°C under stirring, and keep the temperature constant for 1 hour to form a high-viscosity gel-like solution in which the solid powder is uniformly dispersed. Pass the gel suspension into the casting machine and coat it into a slurry layer with a thickness of 1mm. The slurry layer is dried in the drying channel at 110°C for about 0.5 hours, and the solid powder is densely settled to form a dense xerogel....

Embodiment 3

[0039] Lithium-ion battery cathode material lithium iron phosphate sol coating preparation method: first disperse 6.5g of natural plant starch in 93.5g of distilled water, then mix 50g of ferric oxalate, lithium nitrate, and triammonium phosphate that meet the stoichiometric ratio into the prepared in the liquid. Use a high-speed shear disperser to disperse for 0.75 hours. Then, it is pulverized by a colloid mill, so that the particle size of the solid powder is further ground to below 1 micron. Put the dispersed liquid into the reaction kettle, slowly raise the temperature to 90°C under stirring, and keep the temperature constant for 3 hours to form a high-viscosity gel-like solution in which the solid powder is uniformly dispersed. Pass the gel suspension into the casting machine and coat it into a slurry layer with a thickness of 2mm. The slurry layer is dried in the drying channel at 105°C for about 0.75 hours, and the solid powder is densely settled to form a dense xerog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com