Method for preparing nickel-doped zinc oxide (NixZn1-xO) magnetic microspheres by alcohol-thermal method

A technology of nixzn1-xo and magnetic microspheres, which is applied in the field of preparation of nickel-doped zinc oxide magnetic microspheres by alcohol thermal method, which achieves the effects of excellent room temperature ferromagnetism, good dispersion and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] At room temperature, weigh 1.3387g Zn(NO 3 ) 2 ·6H 2 O, 0.1454g Ni(NO 3 ) 2 ·6H 2 O, measure 45ml of ethylene glycol into a three-necked flask, mechanically stir at a speed of 650rpm for 30 minutes, then add 4.5g of anhydrous sodium acetate and 1.1ml of polyethylene glycol-200 for ultrasonic dispersion for 45 minutes, until completely dissolved and dispersed evenly , and then pour the above solution into the reaction kettle, raise the temperature to 180° C., and react for 12 hours. After the reaction was completed, cool naturally to room temperature, centrifuge at 7000rpm for 10 minutes to obtain the product; wash the product 4 times with deionized water and 2 times with absolute ethanol, and then dry at 50°C for 8 hours to obtain Ni 0.1 Zn 0.9 O magnetic microspheres.

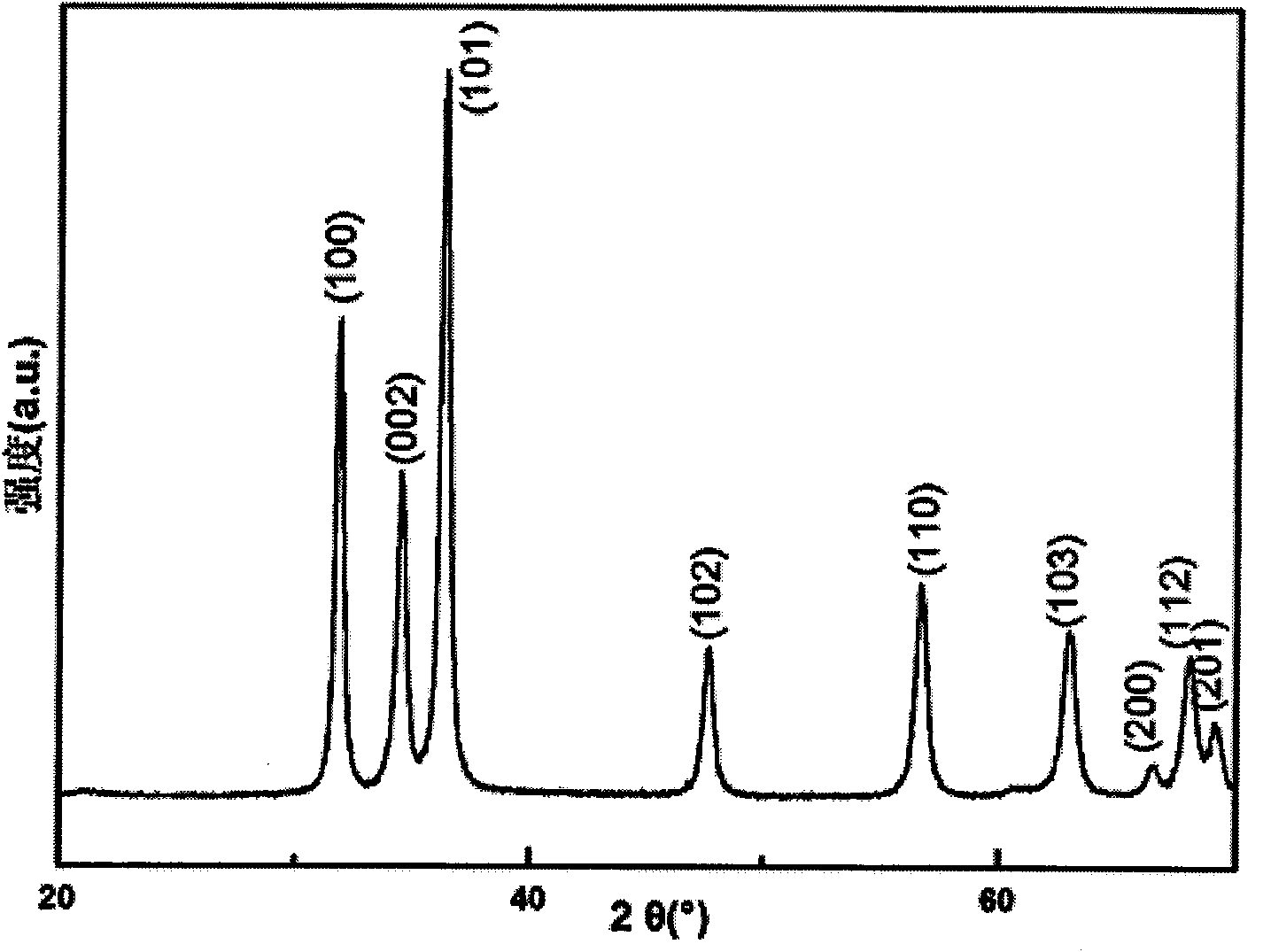

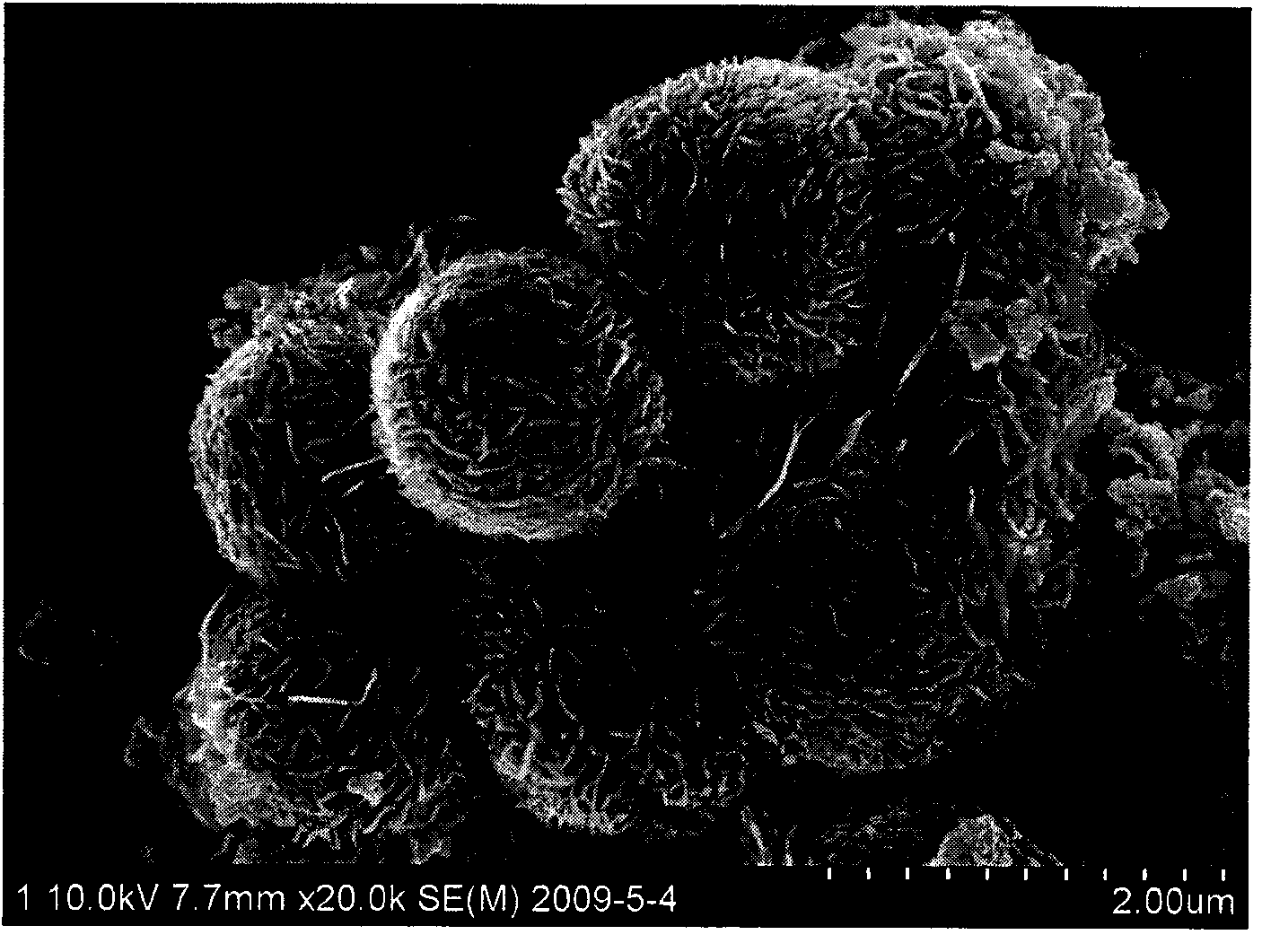

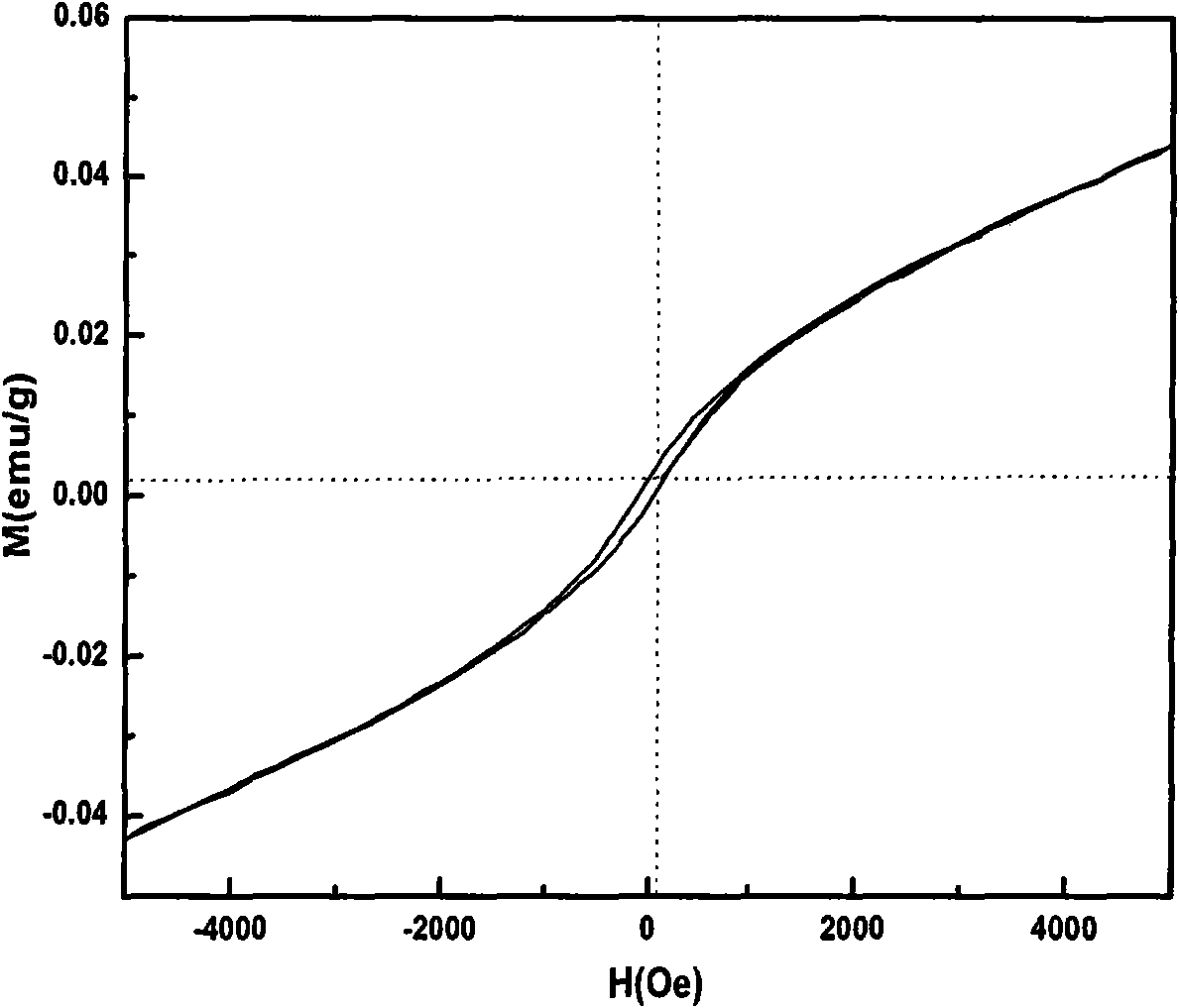

[0033] figure 1 This is the X-ray diffraction pattern of the product synthesized in this example. Compared with the standard XRD pattern, it shows that the synthesized powder is ZnO in hexagona...

Embodiment 2

[0035] At room temperature, weigh 1.041g Zn(CH 3 COO) 2 2H 2O, 0.0622g Ni(CH 3 COO) 2 4H 2 0, measure 55ml of ethylene glycol and put it into a three-necked flask, mechanically stir at a speed of 500rpm for 40 minutes, then add 3g of anhydrous sodium acetate, 1.2ml of polyethylene glycol-200 and ultrasonically disperse for 60 minutes, after completely dissolving and dispersing evenly, Then the above solution was poured into the reactor, the temperature was raised to 200° C., and the reaction was carried out for 14 hours. After the reaction was completed, it was naturally cooled to room temperature and centrifuged at 6000rpm for 20 minutes to obtain the product; the product was washed with deionized water and absolute ethanol three times respectively, and then dried at 60°C for 5 hours to obtain Ni 0.05 Zn 0.95 O magnetic colloidal microspheres.

[0036] Figure 4 This is the X-ray diffraction pattern of the product synthesized in this example. Compared with the standar...

Embodiment 3

[0038] At room temperature, weigh 0.5111g ZnCl 2 , 0.2971g NiCl 2 ·6H 2 0, measure 35ml of ethylene glycol and put it into a three-necked flask, mechanically stir at a speed of 800rpm for 20 minutes, then add 6g of anhydrous sodium acetate and 1ml of polyethylene glycol-200 for ultrasonic dispersion for 30 minutes, until completely dissolved and dispersed evenly, then The above solution was poured into the reaction kettle, the temperature was raised to 220°C, and the reaction was carried out for 10 hours. After the reaction was completed, it was naturally cooled to room temperature and centrifuged at 8000rpm for 5 minutes to obtain the product; the product was washed with deionized water 6 times and absolute ethanol once, and then dried at 40°C for 12 hours to obtain Ni 0.25 Zn 0.75 O magnetic colloidal microspheres.

[0039] Image 6 It is the X-ray diffraction pattern of the synthesized product in this example, and compared with the standard XRD pattern, it shows that t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com