Preparation of magnetic reduced graphene oxide composite material and method for removing quinolone antibiotics from water by the same

A technology of composite materials and quinolones, which is applied in the field of water treatment, can solve the problems of easy aggregation of magnetic nanoparticles, poor dispersion, and influence on the adsorption effect, and achieve the effect of easy separation, simple process, and low production equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

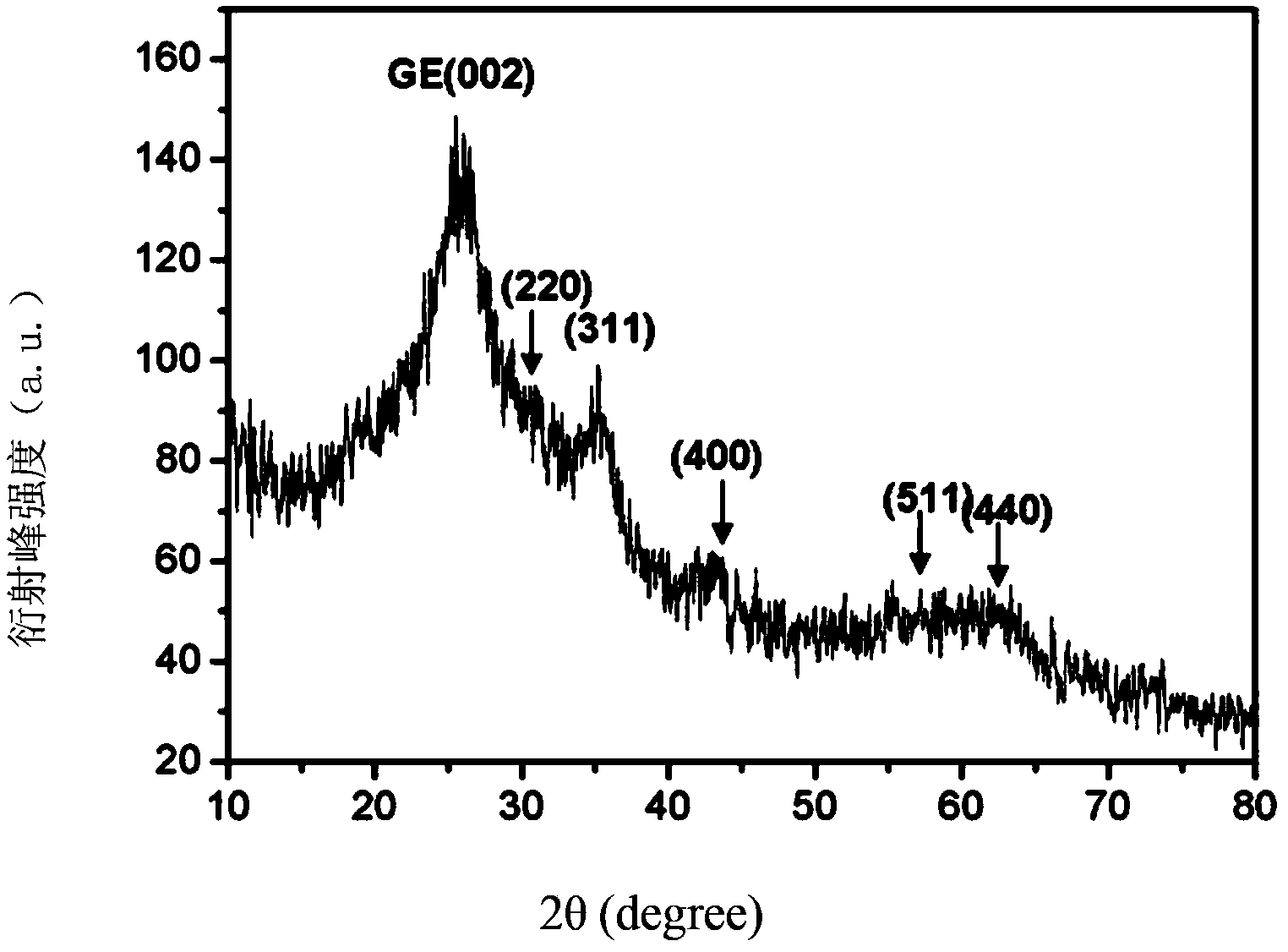

Embodiment 1

[0049] (1) First add 0.025g of graphene oxide into 20ml of ethylene glycol, the concentration of graphene oxide is 1.25g / L, ultrasonic for 3 hours, so that the graphene oxide is evenly mixed in ethylene glycol.

[0050] (2) Dissolve 0.201g of sodium citrate in 15ml of ethylene glycol, the concentration of sodium citrate is 13.4mg / L, heat to 60°C, and let it react for 20 minutes.

[0051] (3) At room temperature, 0.1g FeCl 3 ·6H 2 O and 0.15 g of urea were dissolved into the sodium citrate and ethylene glycol mixed solution obtained in step (2) with the assistance of strong magnetic stirring to obtain the ethylene glycol mixed solution of iron salt and urea.

[0052] (4) The graphene oxide / ethylene glycol mixed solution obtained in step (1) and the ethylene glycol mixed solution of iron salt and urea obtained in step (3) were reacted for 1 hour. Then it was transferred to a 50 mL polytetrafluoroethylene-lined stainless steel reaction kettle, reacted at 180 °C for 8 hours, and...

Embodiment 2

[0056] (1) First add 0.025g of graphene oxide into 11ml of ethylene glycol, the concentration of graphene oxide is 2.27g / L, and sonicate for 3 hours to mix the graphene oxide in ethylene glycol evenly.

[0057] (2) Dissolve 0.75g of sodium citrate in 15ml of ethylene glycol, the concentration of sodium citrate is 50.0g / L, heat to 80°C, and let it react for 50 minutes.

[0058] (3) At room temperature, 0.1g FeCl 3 ·6H 2 O and 0.325g urea were dissolved into the sodium citrate and ethylene glycol mixed solution obtained in step (2) under the assistance of strong magnetic stirring to obtain the ethylene glycol mixed solution of iron salt and urea.

[0059] (4) The graphene oxide / ethylene glycol mixed solution obtained in step (1) and the ethylene glycol mixed solution of iron salt and urea obtained in step (3) were reacted for 2.5 hours. Then it was transferred to a 50 mL polytetrafluoroethylene-lined stainless steel reactor, reacted at 200 °C for 12 hours, and then cooled natu...

Embodiment 3

[0063] (1) First add 0.025g of graphene oxide into 8ml of ethylene glycol, the concentration of graphene oxide is 3.13g / L, sonicate for 3 hours, so that graphene oxide is evenly mixed in ethylene glycol.

[0064] (2) Dissolve 1.302g of sodium citrate in 15ml of ethylene glycol, the concentration of sodium citrate is 86.8g / L, heat to 70°C, and let it react for 80 minutes.

[0065] (3) At room temperature, 0.1g FeCl 3 ·6H 2 O and 0.5 g of urea were dissolved into the sodium citrate and ethylene glycol mixed solution obtained in step (2) under the assistance of strong magnetic stirring to obtain the ethylene glycol mixed solution of iron salt and urea.

[0066] (4) The graphene oxide / ethylene glycol mixed solution obtained in step (1) and the ethylene glycol mixed solution of iron salt and urea obtained in step (3) were reacted for 4 hours. Then it was transferred to a 50 mL polytetrafluoroethylene-lined stainless steel reaction kettle, reacted at 220°C for 24 hours, and then c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com