Method and device for rapidly and continuously preparing zeolite molecular sieve from solid waste through ultraviolet irradiation

A technology of solid waste and zeolite molecular sieve, which is applied in chemical/physical/physical chemical processes, chemical instruments and methods, chemical/physical processes, etc., which can solve the problem of limited sources of synthetic raw materials, long production cycles, and large environmental pollution. to achieve excellent selective adsorption performance, improve crystal phase purity, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

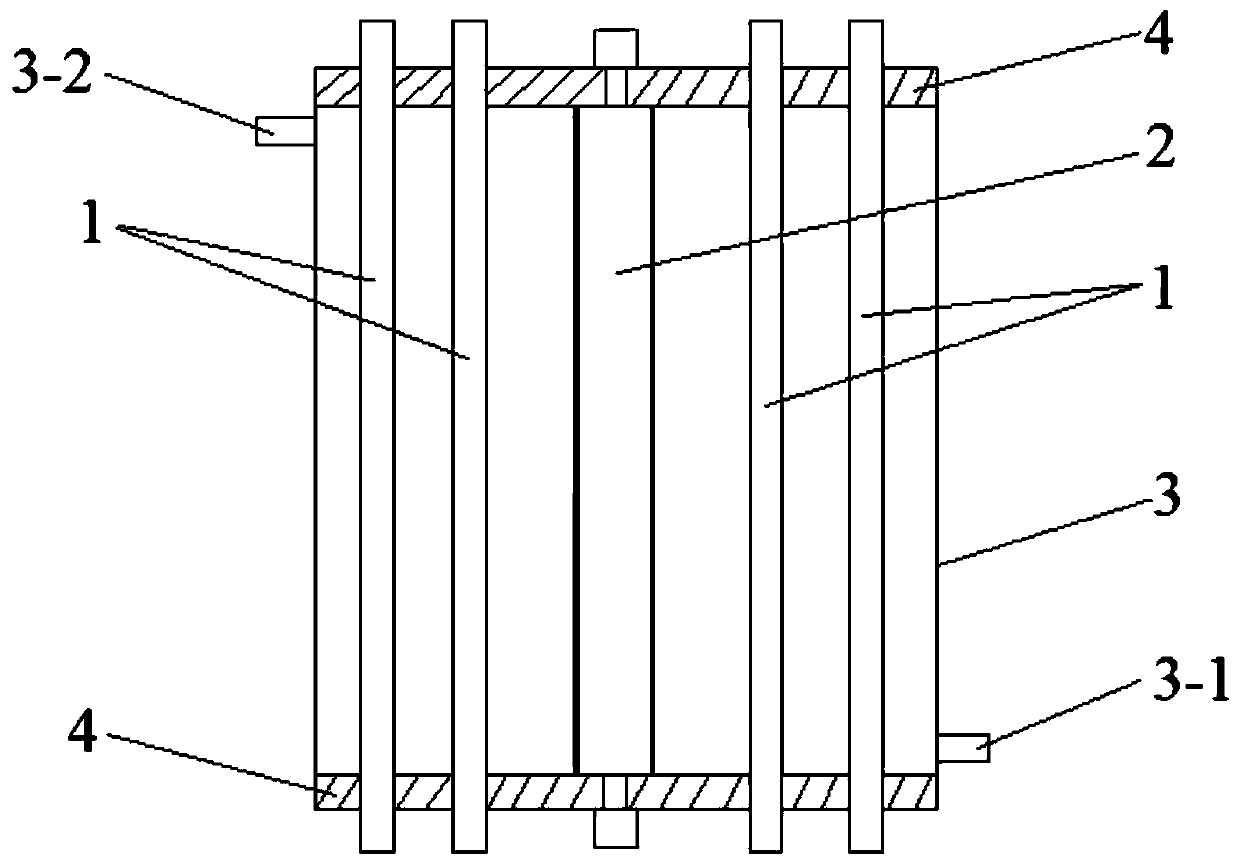

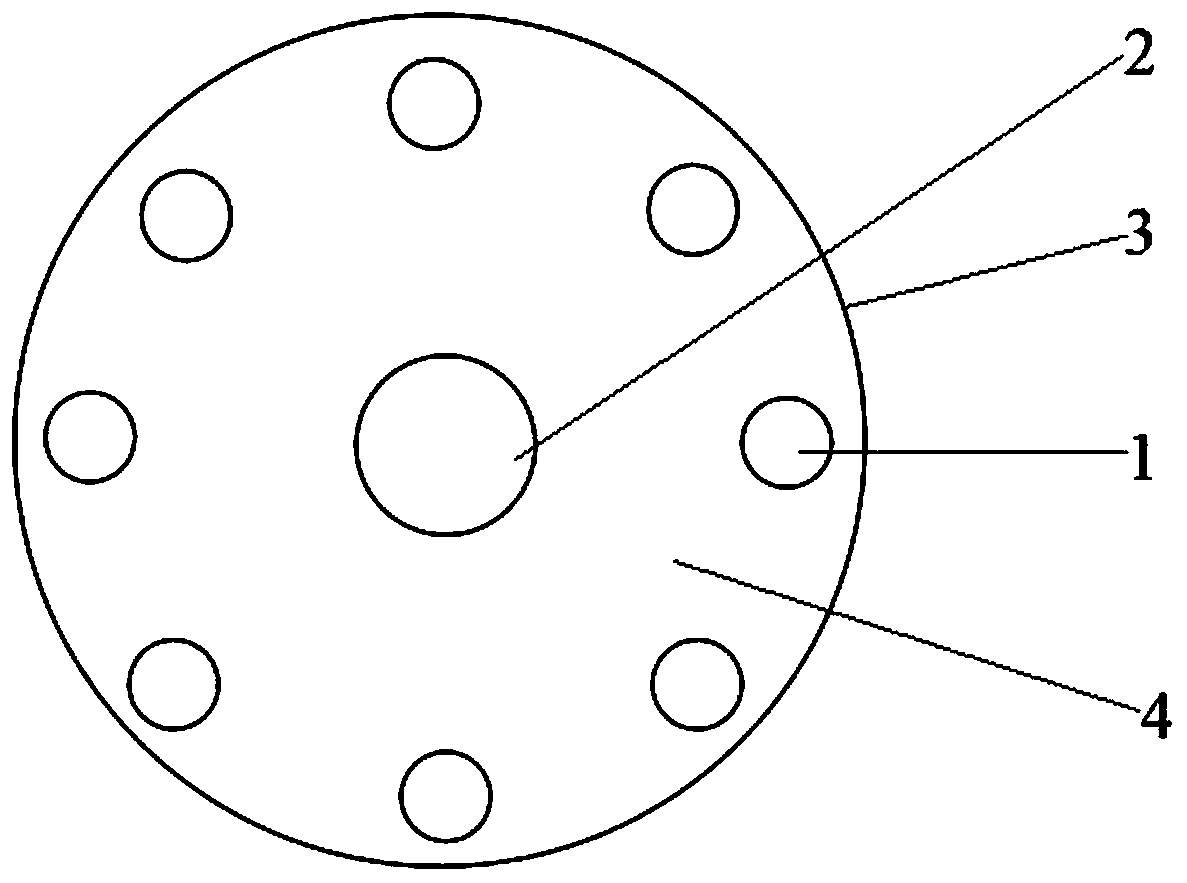

[0048] In this example, the schematic diagram of the device for rapidly and continuously preparing zeolite molecular sieves by ultraviolet irradiation is as follows Figure 1~2 shown, where figure 1 is a cross-sectional view of the device, figure 2 is a schematic diagram of the top of the device.

[0049] The device includes a channel unit composed of eight channels 1, an ultraviolet lamp 2 for applying ultraviolet light to the channel unit, and a temperature control structure 3 for applying temperature control to the channel unit. The device is used in conjunction with a syringe pump to pump molecular sieve precursors into the channel unit.

[0050] The temperature control structure 3 is composed of a channel unit accommodating part and a structure that provides constant temperature circulating water to the channel unit accommodating part. The channel unit accommodating part is a cylinder, and the lower part of the cylinder is provided with a constant temperature circulati...

Embodiment 2

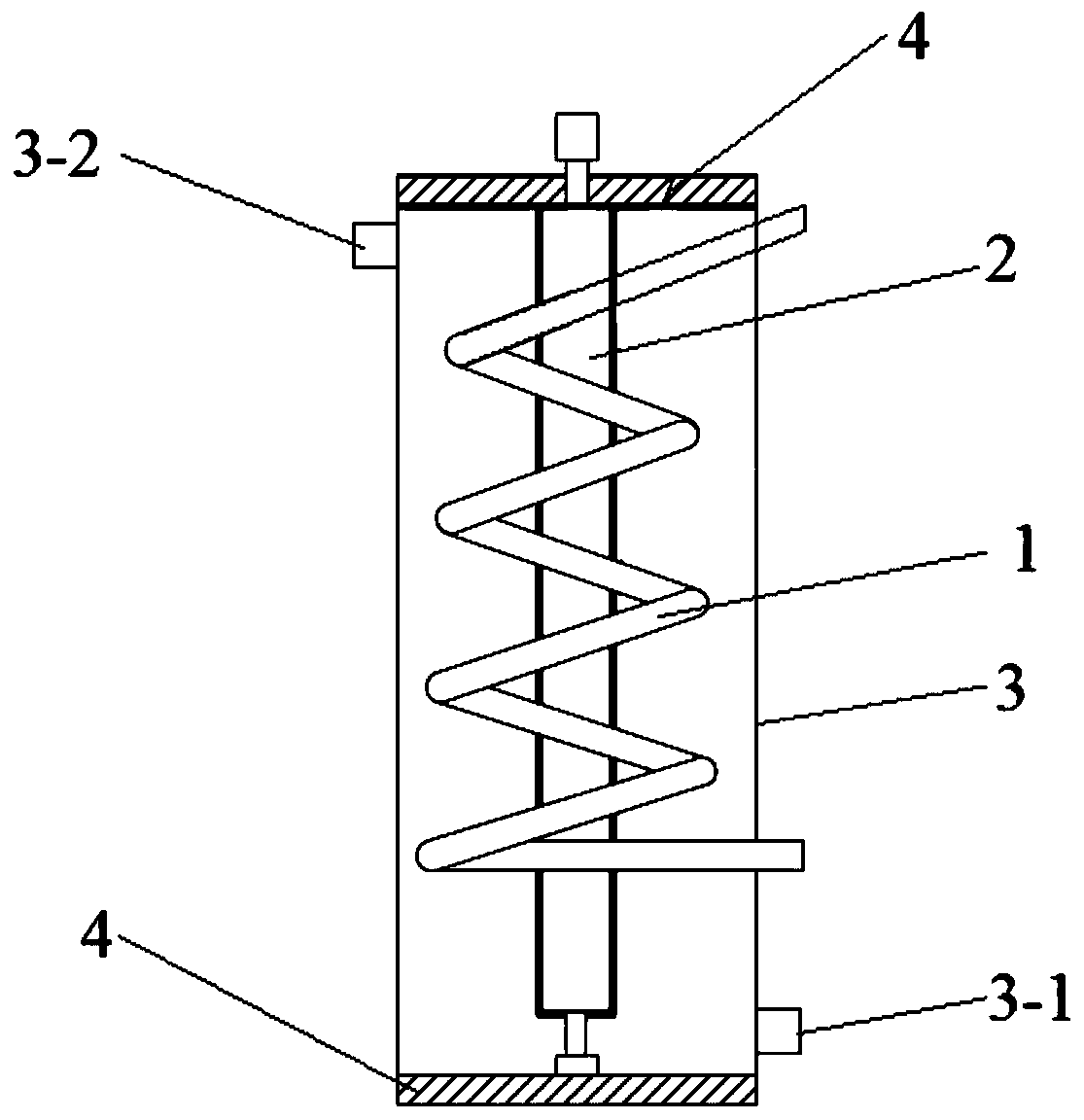

[0052] In this example, the schematic diagram of the device for rapidly and continuously preparing zeolite molecular sieves by ultraviolet irradiation is as follows image 3 shown.

[0053] The device includes a channel unit consisting of a channel 1, an ultraviolet lamp 2 for applying ultraviolet light to the channel unit, and a temperature control structure 3 for applying temperature control to the channel unit. The device is used in conjunction with a syringe pump to Pump the molecular sieve precursor into the channel cell.

[0054]The temperature control structure 3 is composed of a channel unit accommodating part and a structure that provides constant temperature circulating water to the channel unit accommodating part. The channel unit accommodating part is a cylinder, and the lower part of the cylinder is provided with a constant temperature circulating water inlet, a The upper part is provided with a constant temperature circulating water outlet, and the two ends of t...

Embodiment 3

[0056] In this example, the industrial waste slag lithium silicon powder produced in the production process of lithium carbonate is used as raw material, and the device described in Example 1 is used to continuously prepare zeolite molecular sieves, and the steps are as follows:

[0057] (1) Grinding the lithium silicon powder and passing it through a 200-mesh sieve to obtain a raw material powder.

[0058] (2) According to the ratio of adding 10 mL of hydrochloric acid with a concentration of 1 mol / L per 1 g of raw material powder, mix the raw material powder with the hydrochloric acid, stir and react for 2 hours, filter, wash the obtained filter residue until neutral, and put Dry for 12 hours to obtain the pretreated raw material.

[0059] (3) Fully grind and mix the pretreated raw material and sodium hydroxide solid according to the mass ratio of 1:1.7, roast at 500°C for 120min under a nitrogen atmosphere, then grind and pass through a 200-mesh sieve to obtain a roasted pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com