Preparation method and application of {010} high-energy facet exposed BiOCl nanosheet

A {010}, nanosheet technology, applied in the field of new functional materials, can solve the problems of high manufacturing cost, cumbersome steps, unsuitable for industrial production, etc., and achieves environmental friendliness, simple preparation process, and easy control of microscopic morphology and particle size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Mix the raw materials 10mmol bismuth nitrate, 10mmol potassium chloride and 30mmol potassium hydroxide evenly, add the raw material mixture and corundum balls into the ball mill tank at a mass ratio of 1:80, and ball mill for 6 hours at a speed of 1000rpm to obtain the precursor Then put the precursor in the muffle furnace, set the heating rate at 5°C / min, keep the temperature at 450°C for 4 hours, cool to room temperature, take out the sample, and then wash the sample with deionized water and absolute ethanol to remove impurities 1. Solid-liquid separation is carried out by filtration, and finally the solid product obtained by filtration is vacuum-dried at 100° C. for 12 hours to prepare a BiOCl nanosheet material.

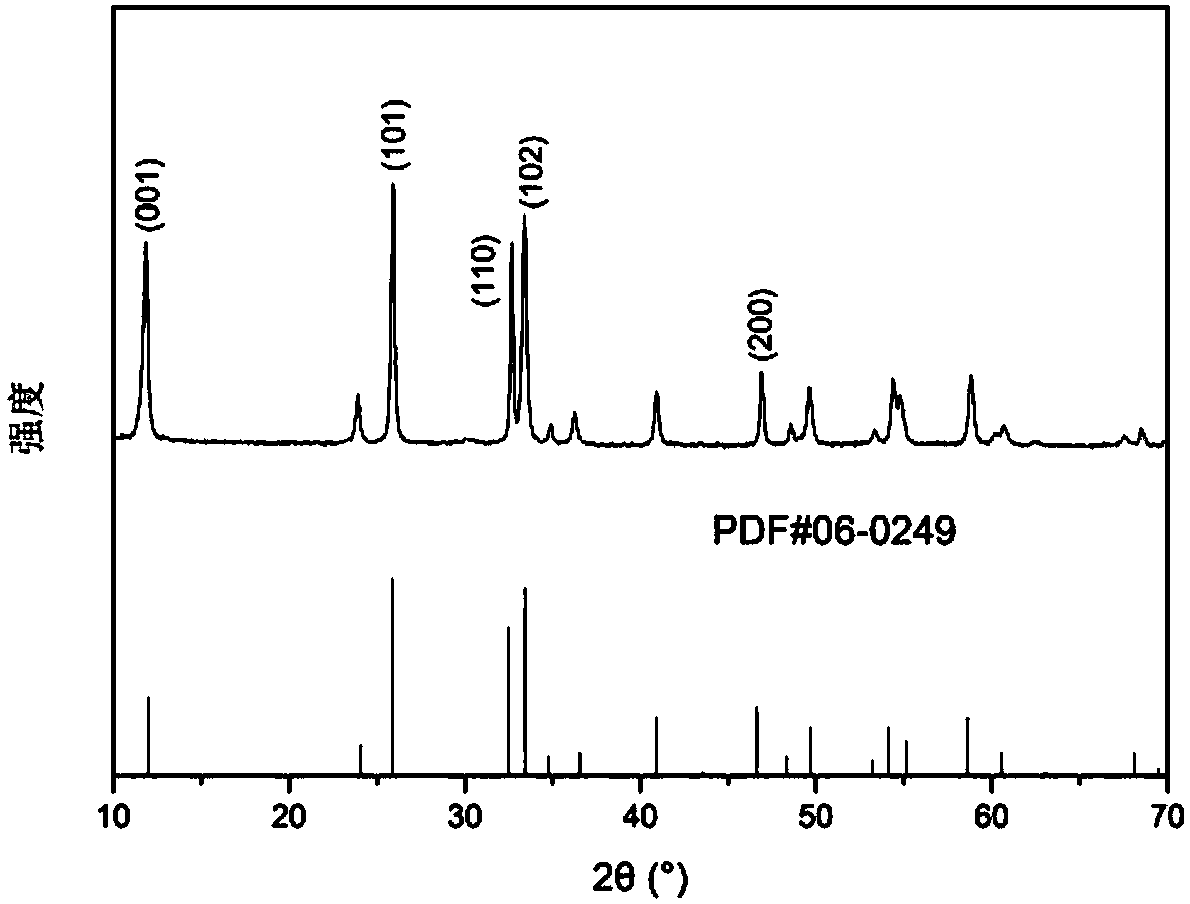

[0029] 2. Carry out X-ray diffraction test to the BiOCl nano sheet material prepared in embodiment 1, as figure 1 As shown, the crystal phase of the obtained BiOCl nanosheet product is pure, without other impurity peaks, and the crystallinity is good. ...

Embodiment 2

[0031] 1. Mix the raw materials 5mmol bismuth oxide, 10mmol zinc chloride and 50mmol potassium citrate evenly, add the raw material mixture and porcelain grinding balls into the ball milling tank at a mass ratio of 1:100, and ball mill for 8 hours at a speed of 800rpm to obtain Then put the precursor in the muffle furnace, set the heating rate at 5°C / min, keep the temperature at 500°C for 2 hours, cool to room temperature, take out the sample, and then wash the sample with deionized water and absolute ethanol to remove Miscellaneous, solid-liquid separation was carried out by filtration, and finally the solid product obtained by filtration was dried at 110° C. for 12 hours to prepare BiOCl nanosheet material.

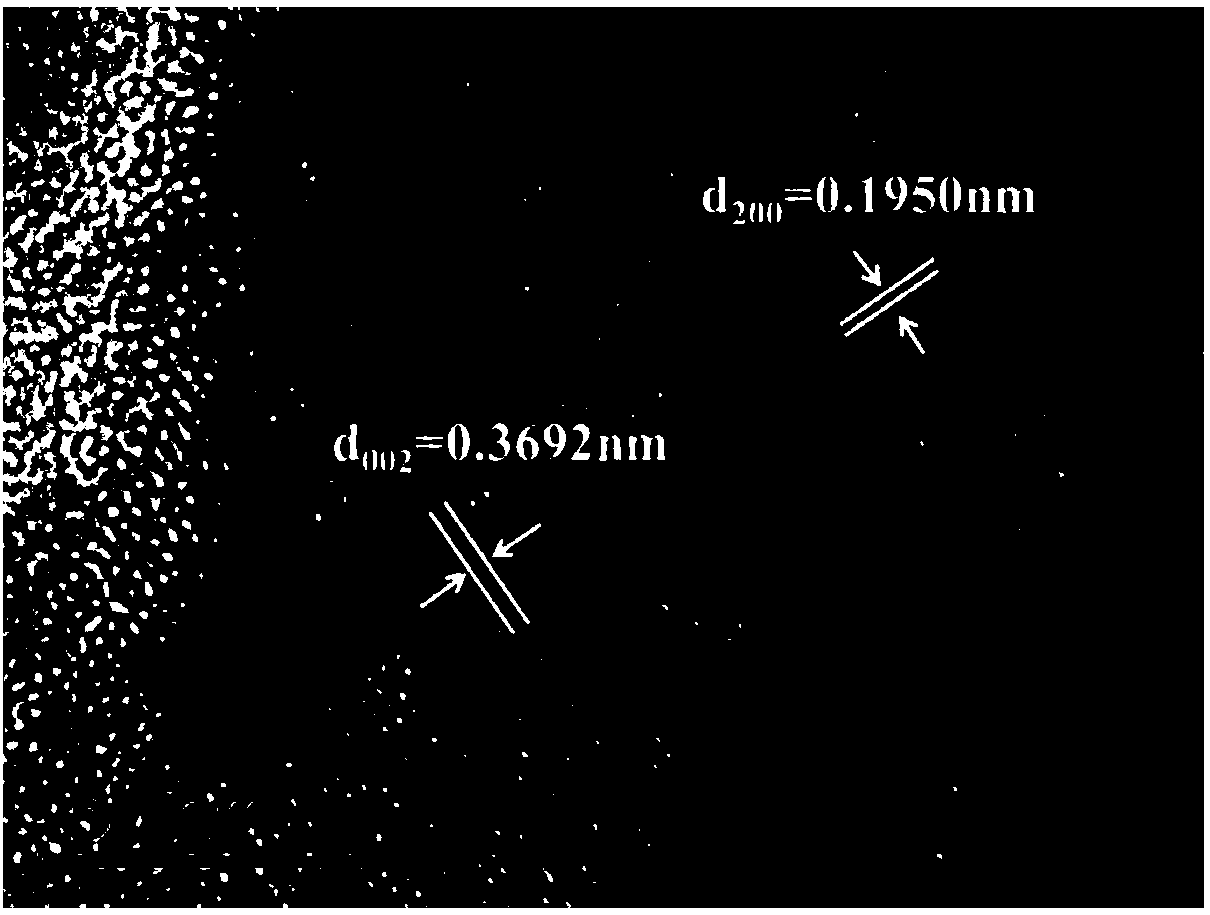

[0032] 2. Carry out transmission electron microscope test to the BiOCl nano sheet material prepared by embodiment 2, as figure 2 , 3 as shown, figure 2 The two lattice fringe spacings 0.3692nm and 0.1950nm marked in , respectively match the (002) crystal plane and (...

Embodiment 3

[0034] 1. Mix the raw materials 5mmol bismuth sulfate, 5mmol ammonium chloride and 50mmol sodium acetate evenly, add the raw material mixture and stainless steel balls into the ball mill tank at a mass ratio of 1:50, and ball mill for 4 hours at a speed of 1500rpm to obtain the precursor , and then put the precursor in the muffle furnace, set the heating rate to 5°C / min, keep the temperature at 400°C for 5h, cool to room temperature, take out the sample, and then wash the sample with deionized water and absolute ethanol to remove impurities, The solid-liquid separation was carried out by filtration, and finally the solid product obtained by filtration was dried at 90° C. for 16 h to prepare the BiOCl nanosheet material.

[0035] 2. Carry out scanning electron microscope test to the BiOCl nano sheet material prepared by embodiment 3, as Figure 4As shown, it can be seen from the scanning electron microscope image of the sample that the prepared BiOCl nanosheet material is compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com