Green synthesis method of lanthanum-based perovskite

A synthesis method and perovskite technology, applied in chemical instruments and methods, cobalt compounds, manganese compounds, etc., can solve the problems of complex process, many influencing factors, and low efficiency of electrospinning, and achieve simple preparation process and source Broad, content-rich effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

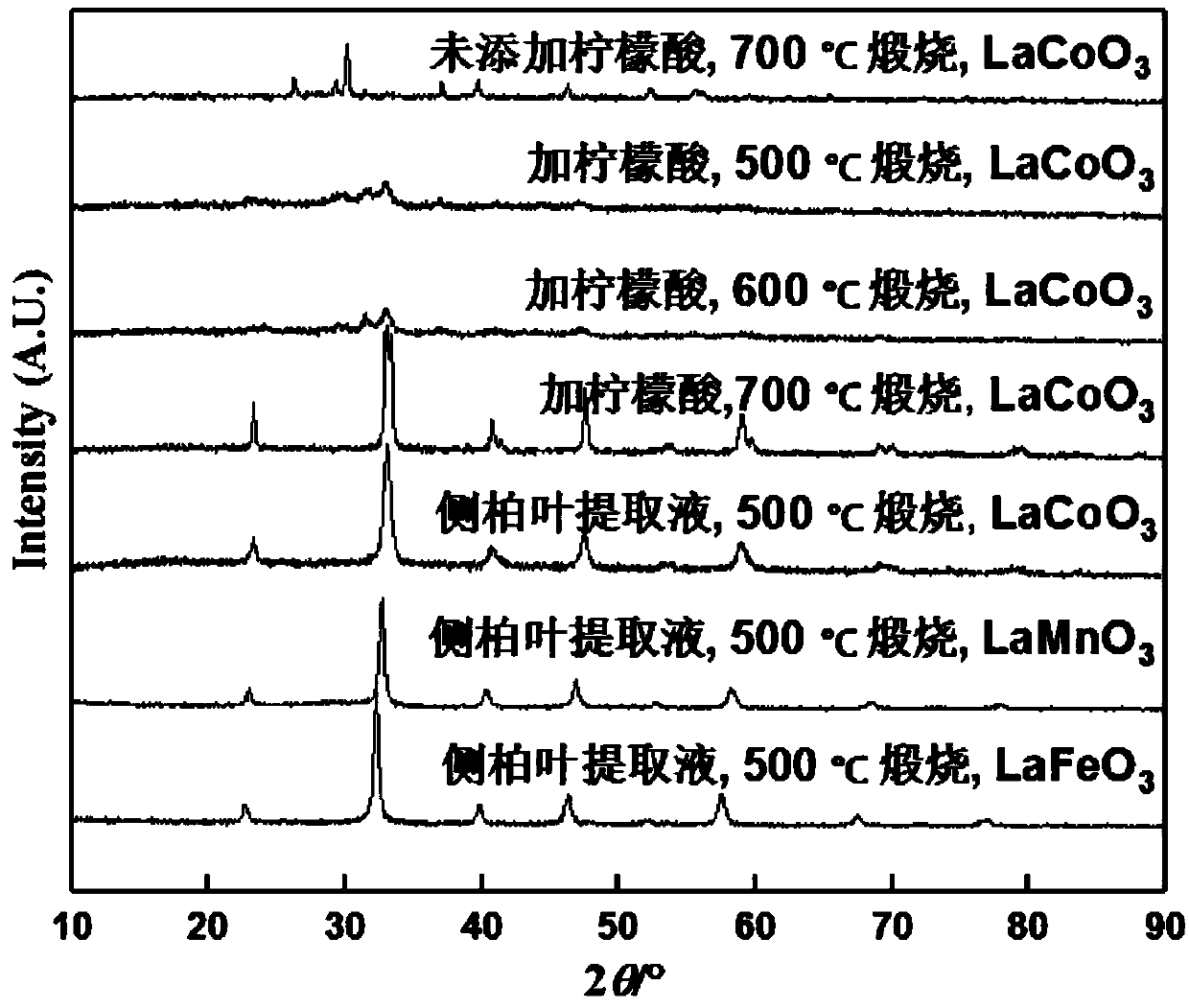

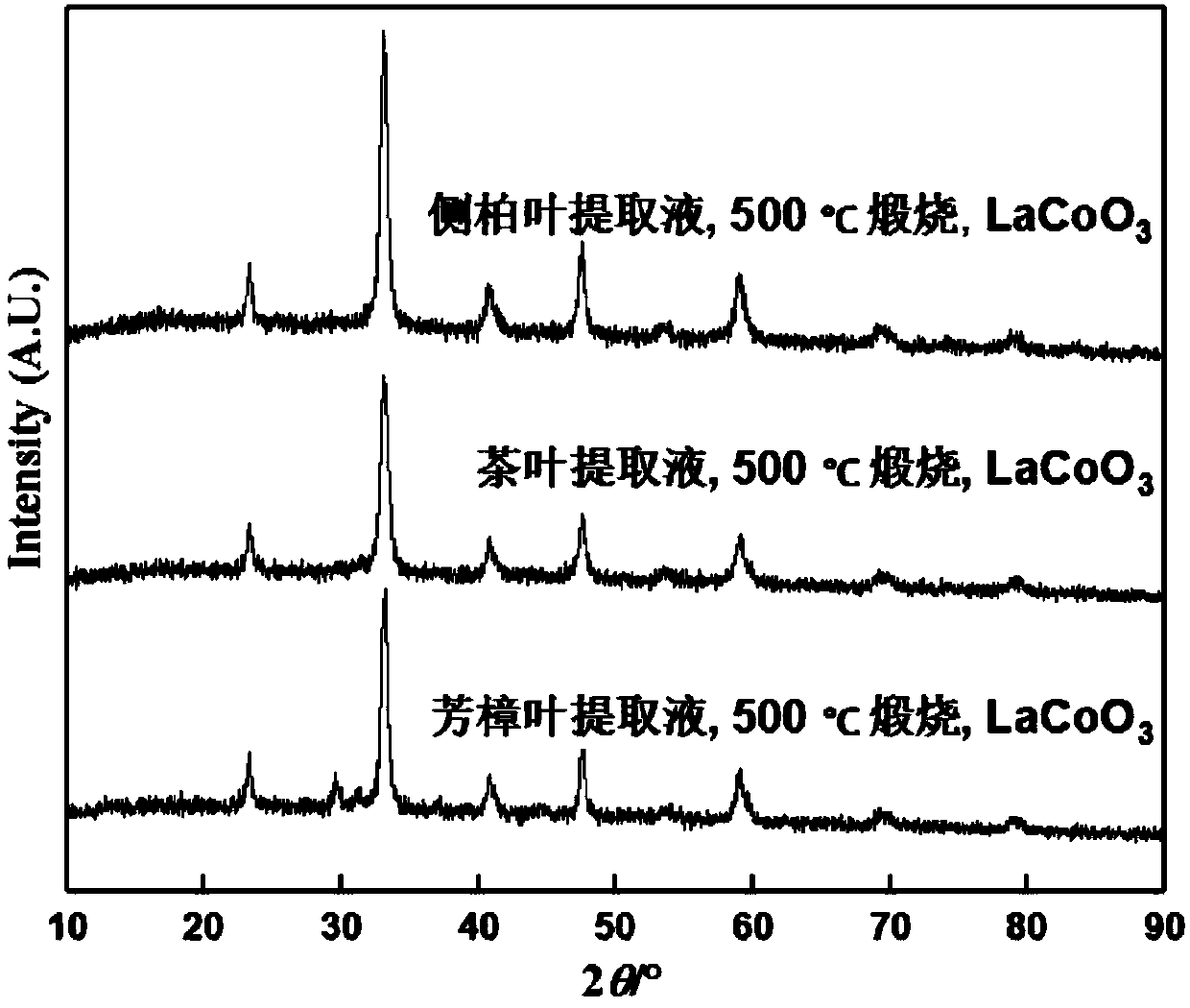

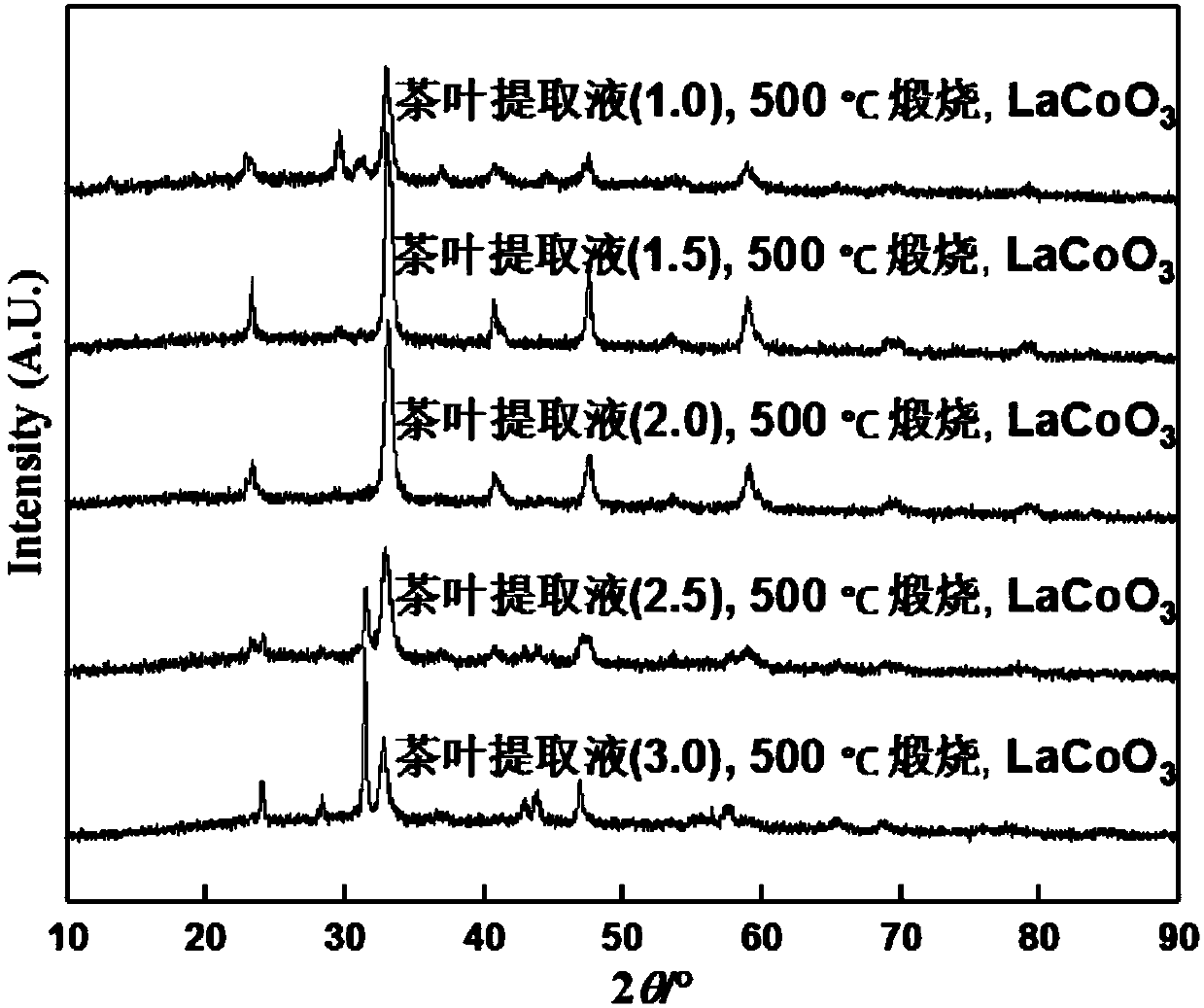

[0029] 1) Wash the leaves of orientalis leaves with distilled water, remove sundries and dust on the surface, dry them in an oven at 80°C, and then crush them with a crusher to obtain powder of leaves of orientalis leaves; weigh 8.0 g of leaves of orientalis leaves, Mix it with 150mL deionized water, shake and extract in a water bath at 30°C at a speed of 170r / min for 24h, then filter with suction to prepare the extract of oriental cypress leaves;

[0030] 2) Weigh 0.4000g lanthanum nitrate (La(NO 3 ) 3 ·6H 2 O) and 0.2688g cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O) in the Erlenmeyer flask of 50mL (ratio of the amount of substance of lanthanum nitrate and cobalt nitrate n 1 :n 2 =1:1), and add 20mL of orientalis leaf extract, stir magnetically at room temperature for 1 hour to fully dissolve the lanthanum nitrate and cobalt nitrate, put the solution in an oven at 80°C for 24 hours, and then dry the The sample was calcined in a muffle furnace, and the temperature was raised fr...

Embodiment 2

[0032] 1) Wash the leaves of orientalis leaves with distilled water, remove sundries and dust on the surface, dry them in an oven at 50°C, and then crush them with a crusher to obtain powder of leaves of orientalis leaves; weigh 10.0 g of leaves of orientalis leaves, Mix it with 150mL deionized water, shake and extract in a water bath at 30°C at a speed of 170r / min for 24h, then filter with suction to prepare the extract of oriental cypress leaves;

[0033] 2) Weigh 0.4000g lanthanum nitrate (La(NO 3 ) 3 ·6H 2 O) and 0.2264g manganese acetate (C 4 h 6 MnO 4 4H 2 O) in the Erlenmeyer flask of 50mL (ratio of the amount of substance of lanthanum nitrate and manganese acetate n 1 :n 2 =1:1), and add 20mL of orientalis leaf extract, stir magnetically at room temperature for 0.5h to fully dissolve the lanthanum nitrate and manganese acetate, put the solution in an oven at 70°C for 36h, and then dry the The dry sample was calcined in a muffle furnace, and the temperature was ...

Embodiment 3

[0035] 1) Wash the leaves of orientalis leaves with distilled water, remove sundries and dust on the surface, dry them in an oven at 65°C, and then crush them with a crusher to obtain powder of leaves of orientalis leaves; weigh 8.0 g of leaves of orientalis leaves, Mix it with 150mL deionized water, shake and extract in a water bath at 30°C at a speed of 170r / min for 24h, then filter with suction to prepare the extract of oriental cypress leaves;

[0036] 2) Weigh 0.4000g lanthanum nitrate (La(NO 3 ) 3 ·6H 2 O) and 0.3732g iron nitrate (Fe(NO 3 ) 3 9H 2 O) in the Erlenmeyer flask of 50mL (ratio of the amount of substance of lanthanum nitrate and ferric nitrate n 1 :n 2= 1:1), and add 20mL of orientalis leaf extract, stir magnetically at room temperature for 2 hours to fully dissolve the lanthanum nitrate and ferric nitrate, put the solution in an oven at 90°C for 48 hours, and then dry the The sample was calcined in a muffle furnace, and the temperature was raised from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com