Liquid organic silicon optical adhesive as well as preparation method and application thereof

A silicone and optical adhesive technology, applied in the direction of bonding methods, adhesives, adhesive additives, etc., can solve the problems of low interface adhesion, low cohesive strength, and low aging resistance of optical adhesives, and achieve improved interface adhesion And mechanical properties, overcoming low pressure anti-foaming or glue opening, strong chemical bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0120] This example provides a liquid silicone optical glue, including component A and component B with a mass ratio of 1:1; the specific components are as follows:

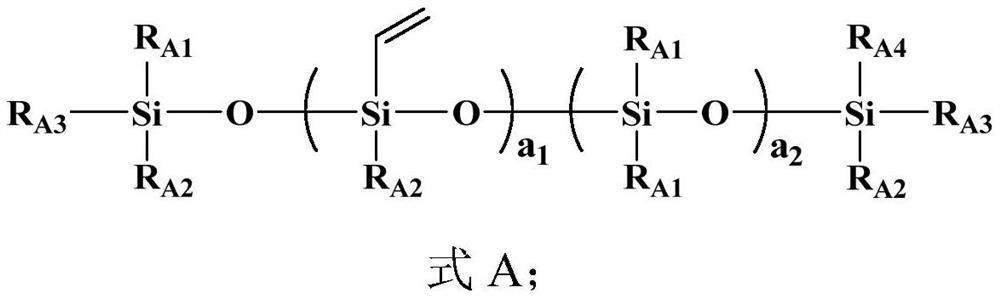

[0121] A component includes by weight: vinyl silicone oil (structure is Viscosity is 300mPa s) 60 parts, vinyl MQ silicone resin (viscosity is 20000mPa s) 30 parts, adjusting aid 10 parts (hydroxyl silicone oil, structure is The viscosity is 20000mPa·s), and the catalyst (the chloroplatinic acid vinyl silicone oil compound solution with a platinum content of 5%) is 15ppm.

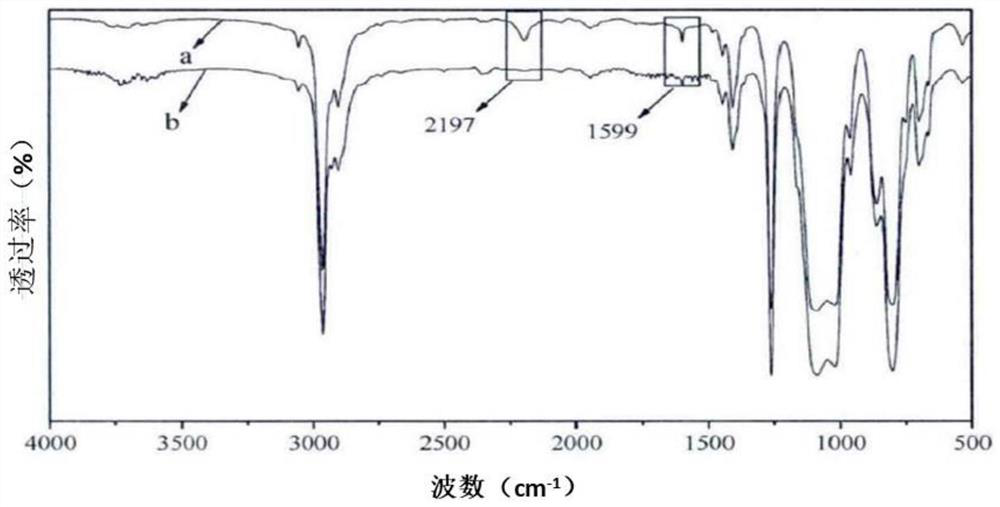

[0122] Component B includes by weight: hydrogen-containing silicone oil (structure is Viscosity is 500mPa s) 60 parts, hydrogen-containing MQ silicone resin (viscosity is 500mPa s) 25 parts, macromolecule modified silane coupling agent B1 (infrared spectrum as shown in figure 1 Shown) 5 parts, other additives (methyl silicone oil, the structure is Viscosity is 500mPa·s) 9.9 parts, inhibitor (ethynyl cyclohexanol) 100ppm.

[0123] The p...

Embodiment 2

[0127] This example provides a liquid silicone optical glue, including component A and component B with a mass ratio of 1:1; the specific components are as follows:

[0128] A component includes by weight: vinyl silicone oil (structure is Viscosity is 10000mPa s) 50 parts, vinyl MDT silicone resin (viscosity is 300mPa s) 30 parts, adjusting aid 20 parts (methyl silicone oil, the structure is Viscosity is 8000mPa·s), catalyst (platinum chloroplatinic acid vinyl silicone oil compound solution with 5% platinum content) 10ppm.

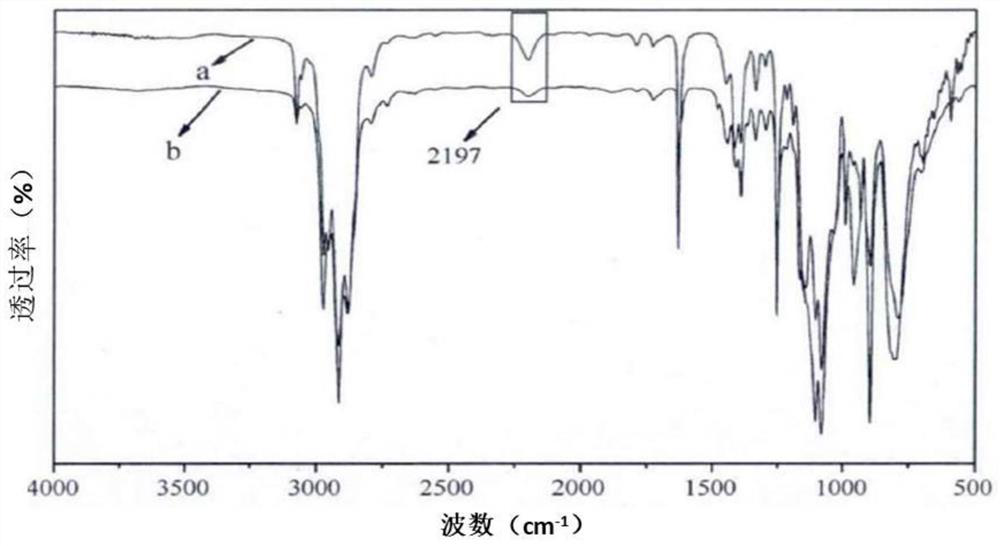

[0129] Component B includes by weight: hydrogen-containing silicone oil (structure is Viscosity is 300mPa s) 50 parts, hydrogen-containing MDT silicone resin (viscosity is 300mPa s) 30 parts, macromolecule modified silane coupling agent B2 10 parts, other additives (structure is x:y=3:1, viscosity is 20000mPa·s) 10 parts, inhibitor (1,1,3-triphenyl-2-propyn-1-ol) 80ppm.

[0130] The preparation method and method of use are the same as in Example 1. ...

Embodiment 3

[0132] This example provides a liquid silicone optical glue, including component A and component B with a mass ratio of 1:1; the specific components are as follows:

[0133] A component includes by weight: vinyl silicone oil (structure is x:y=7:3, 55 parts of viscosity is 50000mPa·s), 30 parts of vinyl MQ silicone resin (viscosity of 20000mPa·s), 15 parts of adjustment aid (methyl silicone oil, the structure is Viscosity is 10000mPa·s), catalyst (platinum chloroplatinic acid vinyl silicone oil compound solution with 5% platinum content) 10ppm.

[0134] Component B includes by weight: hydrogen-containing silicone oil (structure is 55 parts of viscosity is 8000mPa·s), 30 parts of hydrogen-containing MQ silicone resin (viscosity of 5000mPa·s), 5 parts of macromolecule modified silane coupling agent (composition of B2 and B3 with a mass ratio of 3:2), Other additives (structure is x:y=3:1, viscosity is 30000mPa·s) 10 parts, inhibitor (ethynyl cyclohexanol) 80ppm.

[0135] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com