Vacuum attaching device and display mother board attaching method

A bonding device and vacuum technology, applied in the structural connection of printed circuits, optics, instruments, etc., can solve problems such as weak bonding strength, poor precision, substrate misalignment, etc., and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

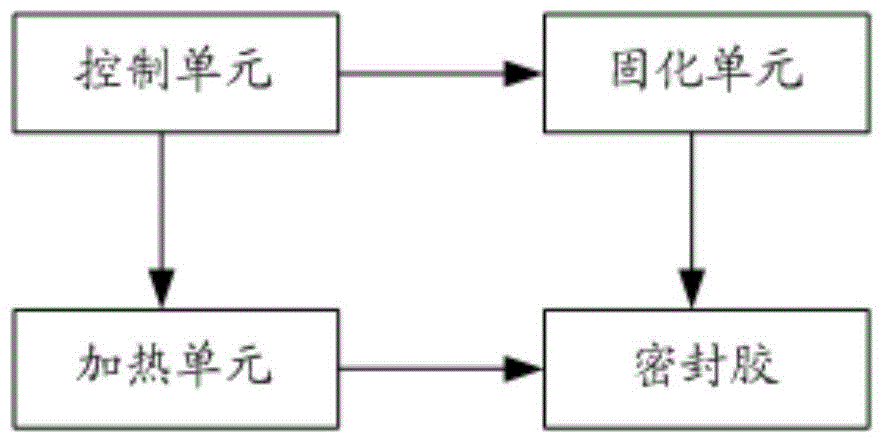

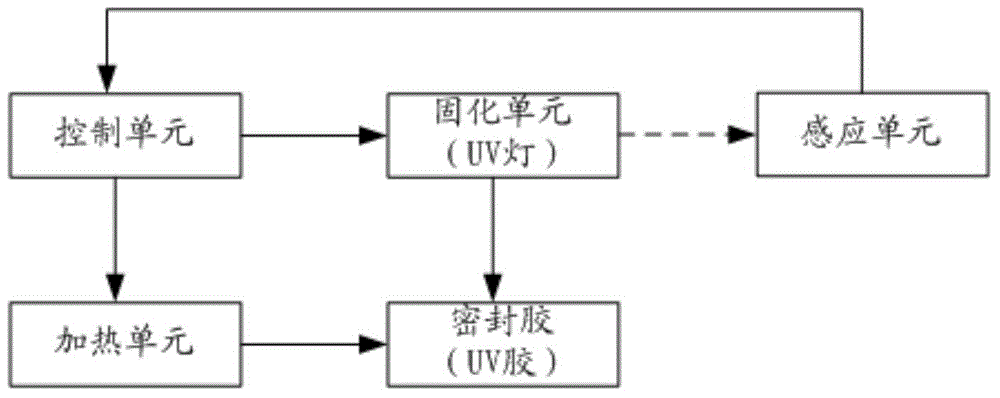

[0033] Such as figure 2 As shown, this embodiment provides a vacuum laminating device, which includes a control unit, an induction unit, a first bearing platform and a second bearing platform arranged oppositely, and a heating unit arranged on the peripheral area of the first bearing platform, The curing unit on the second carrier; the first carrier is used to carry the first mother board, the second carrier is used to carry the second mother board; the peripheral area of the first mother board or the second mother board is coated with The sealant is described by taking as an example that the peripheral area of the first mother board is coated with sealant. Among them, the sealant is UV glue, and the curing unit is a UV lamp.

[0034] Specifically, after the first mother board on the first bearing platform and the second mother board on the second bearing platform are aligned with each other, the UV lamp emits ultraviolet light to the area where the UV glue is located to c...

Embodiment 2

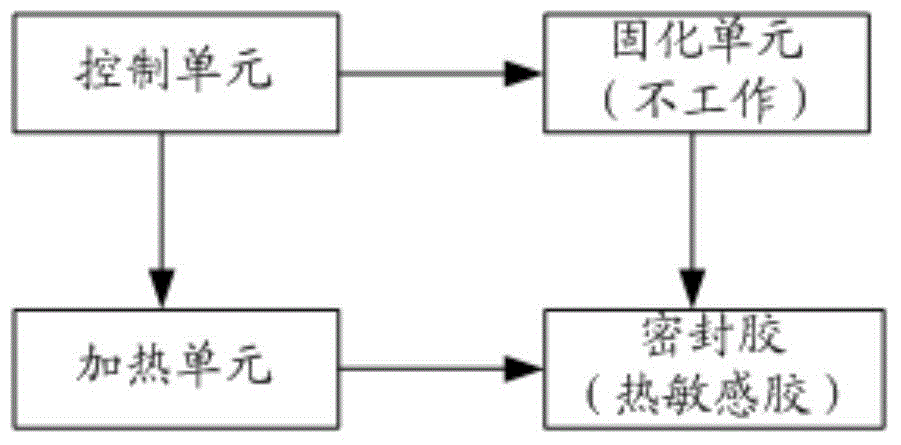

[0046] Such as image 3 As shown, this embodiment provides a vacuum laminating device, which includes a control unit, a first bearing platform and a second bearing platform arranged opposite to each other, a heating unit arranged on the peripheral area of the first bearing platform, and a heating unit arranged on the second bearing platform. The curing unit on the stage; wherein the first bearing stage is used to carry the first mother board, and the second bearing platform is used to carry the second mother board; the peripheral area of the first mother board or the second mother board is coated with sealant, Take the example that the peripheral area of the first mother board is coated with sealant as an example. In this embodiment, the sealant adopts heat-sensitive adhesive. At this time, the control unit controls the curing unit to stop working.

[0047] Since the sealant in this embodiment adopts heat-sensitive glue, it is only necessary to heat the heat-sensitive glue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com