Electrophoretic particle and preparation method thereof, microcapsule and electronic ink screen

A technology of electrophoretic particles and microcapsules, applied in instruments, optics, nonlinear optics, etc., can solve the problems of poor dispersion of electrophoretic particles, poor loading capacity, insensitivity to motion, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

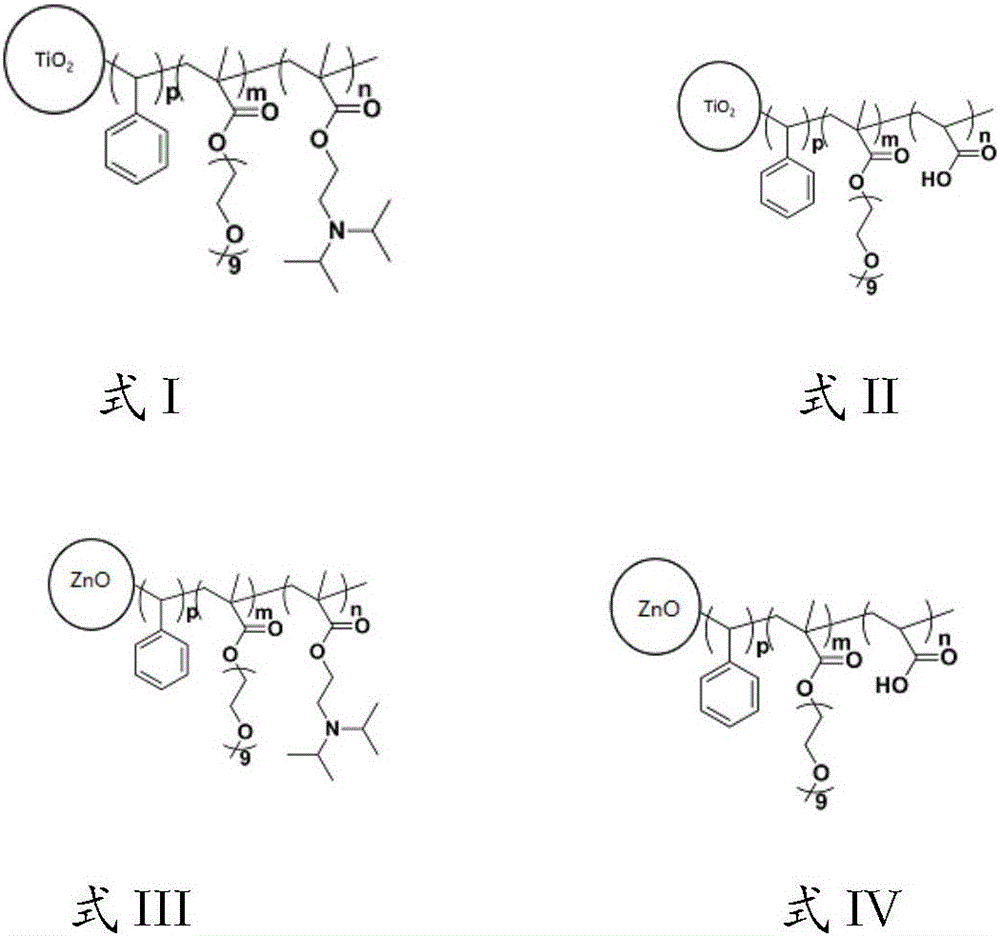

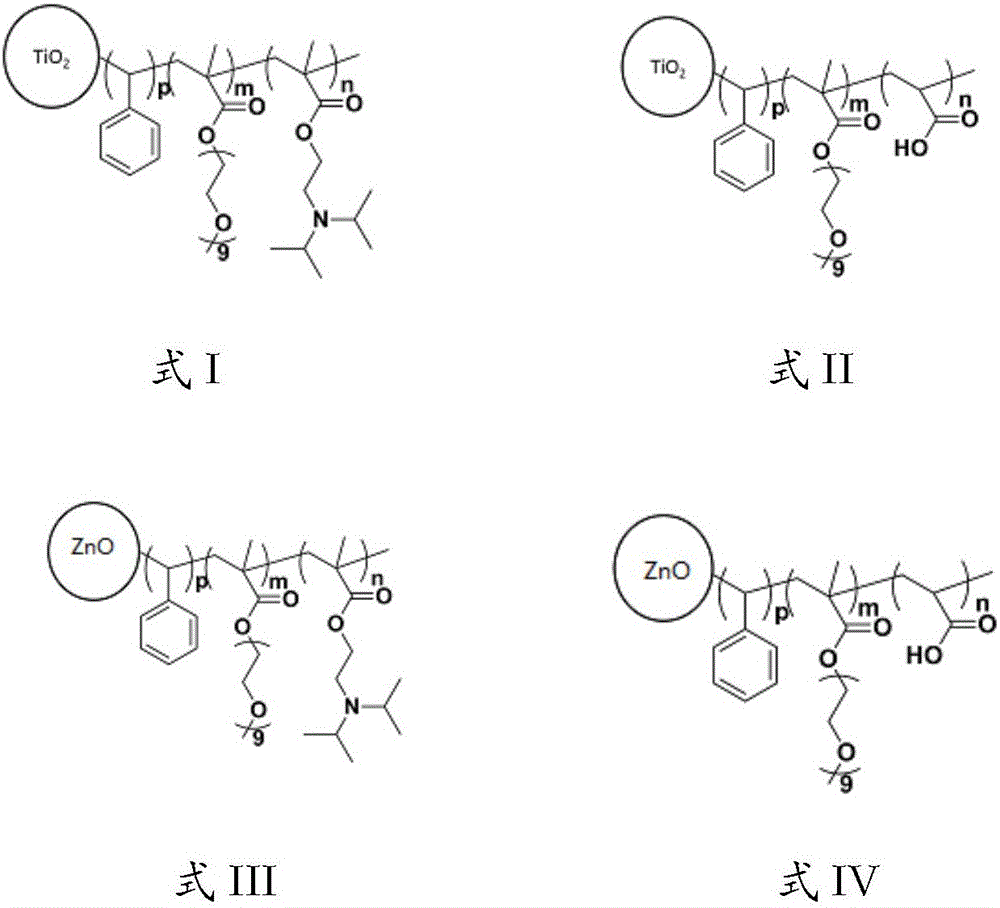

[0047] According to one embodiment of the electrophoretic particle of the present invention, the hydrophilic segment is composed of polyethylene glycol methyl ether methacrylate and polyelectrolyte.

[0048] According to the electrophoretic particle of the present invention, polyoligoethylene glycol methyl ether methacrylate contains the structure of ethylene glycol, so it has the performance of a lubricant, can reduce the surface energy of the electrophoretic particle, and solve the problem that the electrophoretic particle is easy to agglomerate; On the one hand, polyoligoethylene glycol methyl ether methacrylate can stabilize the dispersion of electrophoretic particles through the steric hindrance effect.

[0049] According to the electrophoretic particle of the present invention, the polyelectrolyte is polydiisopropylaminoethyl methacrylate or polyacrylic acid.

[0050] According to the electrophoretic particle of the present invention, the amine group of polydiisopropylam...

Embodiment 1

[0088] The preparation method of electrophoretic particles according to the present invention comprises the steps of: modifying the chain transfer agent: the chain transfer agent is trithiocarbonate; TiO 2 The surface of the microspheres contains hydroxyl groups, and 1 equivalent of TiO 2 Microspheres undergo esterification reaction with 5 equivalents of chain transfer agent to modify chain transfer agent; modified polystyrene: 1 equivalent of TiO modified with chain transfer agent 2 Microspheres, living radical polymerization with 40 equivalents of styrene, on TiO modified with a chain transfer agent 2 Polystyrene modified on microspheres; modified oligoethylene glycol methyl ether methacrylate: 1 equivalent of TiO modified with polystyrene 2 Or ZnO microspheres, and 15 equivalents of oligoethylene glycol methyl ether methacrylate for living free radical polymerization, in the modified polystyrene TiO 2 or ZnO microspheres modified with polyethylene glycol methyl ether meth...

Embodiment 2

[0090] The preparation method of electrophoretic particles according to the present invention comprises the steps of: modifying the chain transfer agent: the chain transfer agent is dithiocarbonate; TiO 2 The surface of the microspheres contains hydroxyl groups, and 1 equivalent of TiO 2 Microspheres undergo esterification reaction with 10 equivalents of chain transfer agent to modify chain transfer agent; modified polystyrene: 1 equivalent of TiO modified with chain transfer agent 2 Microspheres, living radical polymerization with 60 equivalents of styrene, on TiO modified with a chain transfer agent 2 The microspheres are modified with polystyrene; modified oligoethylene glycol methyl ether methacrylate: 1 equivalent of TiO modified with polystyrene 2 Microspheres, living radical polymerization with 125 equivalents of oligoethylene glycol methyl ether methacrylate, on polystyrene-modified TiO 2 The microspheres are modified with polyoligoethylene glycol methyl ether methac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com