Aqueous dissociating abrasive cutting fluid used for making solar silicon wafer and its preparation method

A technology of solar silicon wafers and free abrasives, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of unfavorable silicon wafer cleaning, easily polluted equipment, high production costs, etc., to reduce production costs, easy follow-up cleaning, and low production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

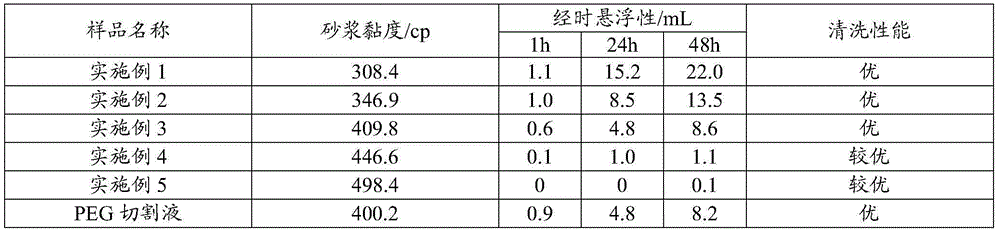

Examples

preparation example Construction

[0022] The present invention is used for the preparation method of the water-based free abrasive cutting liquid that solar silicon chip is made, comprises the following steps:

[0023] 1) Dissolve 0.5-1.2 parts of ACULYN22 / 23, XC-190, Aculyn33 or T-901 in 98-99 parts of deionized water, and stir until it is fully dispersed in deionized water to obtain a mixed solution;

[0024] 2) Adjust the pH value of the mixed solution to 7.0 with triethanolamine;

[0025] 3) Add 0.10-0.20 parts of silicone defoamer SRECN, silicone defoamer SE-47, silicone oil or cutting fluid foam control agent DF-965 and 0.15-0.25 parts of Triethanolamine oleic acid soap, then stirred until the solute is completely dissolved to obtain a water-based free abrasive cutting fluid for solar silicon wafer manufacturing.

Embodiment 1

[0028] Take 0.5 part of T-901 produced by Shanghai Lingling Chemical Industry, dissolve it in 99 parts of deionized water, and stir it with JJ-1 precision booster electric mixer for 30 minutes to fully disperse the T-901 emulsion in the water. The pH was adjusted to 7.0 using triethanolamine as a neutralizing agent. Then add 0.15 parts of silicone defoamer SRECN and 0.2 parts of triethanolamine oleic acid soap to the system, and continue stirring with JJ-1 precision booster electric stirrer until completely dissolved. A water-based free abrasive cutting fluid for solar wafer fabrication was prepared.

Embodiment 2

[0030] Take 0.6 parts of T-901, dissolve in 98.8 parts of deionized water, and stir with JJ-1 precision booster electric mixer for 30 minutes to fully disperse T-901 emulsion in water. The pH was adjusted to 7.0 using triethanolamine as a neutralizing agent. Then add 0.15 parts of silicone defoamer SRECN and 0.2 parts of triethanolamine oleic acid soap to the system, and continue stirring with JJ-1 precision booster electric stirrer until completely dissolved. A water-based free abrasive cutting fluid for solar wafer fabrication was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com