Preparation method of granular titanium-based lithium ion sieve adsorbent with high adsorption capacity

A titanium-based lithium, high-adsorption technology, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of separation and washing difficulties, reduction of specific surface area, difficulty in filtration and separation, etc. Achieve the effect of high lithium adsorption capacity, small specific gravity and simple molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] A method for preparing high adsorbing capacity granulated titanium-based lithium ion sieve adsorbents, including steps:

[0042] Step 1, preparing titanium-based lithium ion sieve precursor powder;

[0043] a) mix the lithium source, titanium dioxide, and dispersant mechanical ball milling, control the purification Li / Ti molar ratio 2: (1-1.2), then add a high temperature mixing agent mix, and the spray is dry to granulate powder, will The grain powder was transferred to a microwave high temperature sintering furnace, and the calcination of 2-3 h, cooled, and the titanium-based lithium ion sieve precursor powder was carried out at 350-650 ° C.

[0044] Or b) mix the titanium source, lithium hydroxide, and appropriate amount of water, control the feed Li / Ti molar ratio 2: (1-1.2), and add 0.5 to 1.5 wt% hydrogen oxygen, stirred under ultrasound 60-90 ° C. 3-6h, sequentially filtered, washed, added high-temperature mixing agent mixing, spray drying to granulated powder, t...

Embodiment 1

[0068] A method for preparing high adsorbing capacity granulated titanium-based lithium ion sieve adsorbents, including steps:

[0069] (1) Preparation of lithium titanate powder;

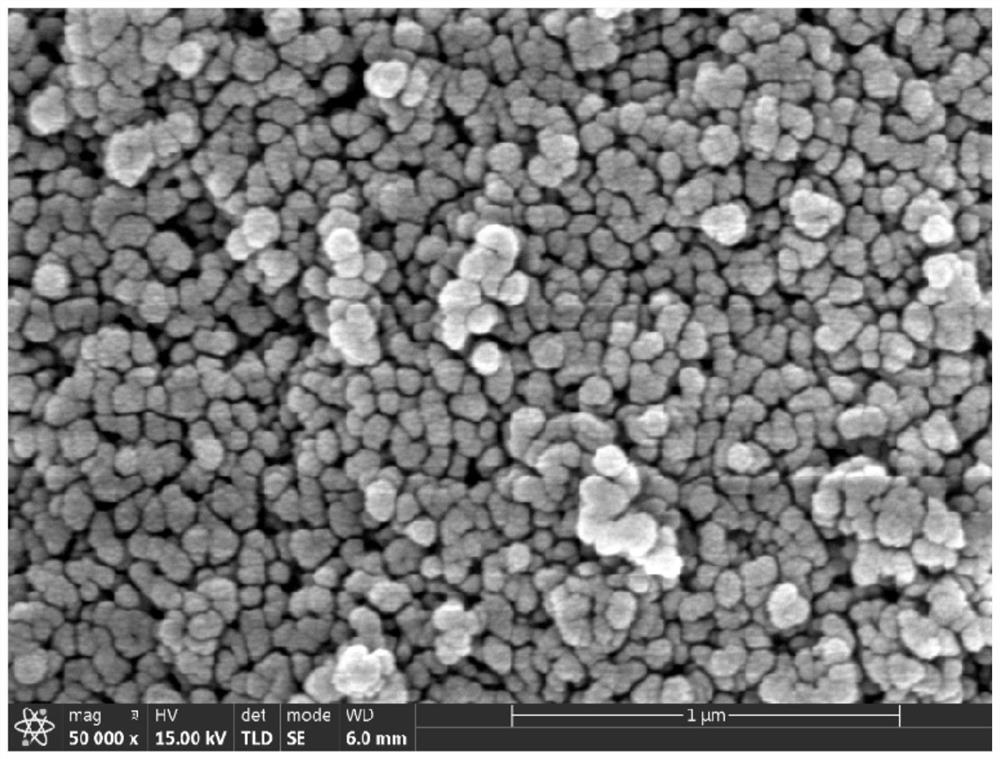

[0070] 19.7 kg of titanium dioxide, 17.4 kg of battery-grade carbonate, 0.1 kg of 1.5 wt% PEG6000 aqueous solution high-speed dispersion, mechanical ball milling control particle size D50 = 550 ~ 850 nm, then add polyether sulfone powder mixing to spray precomive grain, spray The pre-storage temperature is set 200 ° C, and finally calcined the lithium ion screen before the microwave oven 600 ° C. 2 TiO 3 ;

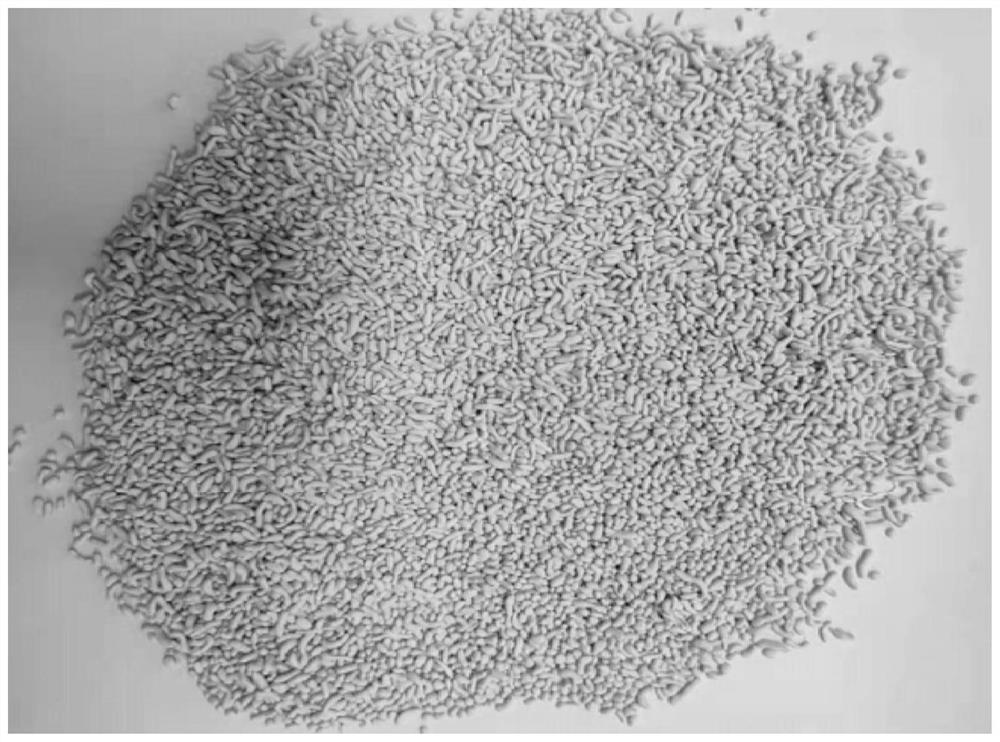

[0071] (2) PES-H 2 TiO 3 Rod-shaped adsorbent

[0072] S1 Preprocessing: After the precursor of the lithium-bias ion sieve precursor was ground, it was 250 mesh, and the lithium-sized ion-sieve precursor was obtained.

[0073] S2 15% PES sol formulation: Take 2.7 kg of PES (polyether sulfone) to add 15 l of dimethylacetamide, continuously stirred in a 50 ° C water bath to completely dissolve, 15% P...

Embodiment 2

[0086] (1) Preparation of lithium titanate powder;

[0087] 40 kg of titanium dioxide was mixed with 10 kg of water into a hierarrier, 10.5 kg of solid lithium hydroxide and mixed stirring uniform; the ultrasonic frequency was 10 ° C under conditions, and the reaction was stirred at normal pressure for 6 h, and the reaction process was added dropwise (total) 30% hydrogen oxide water is about 100 mL), filtered, washed, washed, obtained by tidal lithium ion sieve powder, filtrate returning generic cycle; wet material is pulped, add 0.1 kg of polymer pore agent polyethersulfone mixed, mixed, spray Pre-enrichment to 450 ° C under air atmosphere, calcined for 3 h, cool to room temperature to obtain a lithium-ion sieve Li 2 TiO 3 .

[0088] (2) PES-H 2 TiO 3 Rod-shaped adsorbent

[0089] PES-H 2 TiO 3 The preparation process of the rod-shaped adsorbent is in Example 1, and the granulation is used for centrifugal devices, and the slurry is over 80 mesh sieve, the drum diameter is 60 mm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com